Nanocarbon-loaded atomic-scale dispersion rhodium catalyst, preparation method thereof, and application of catalyst in hydrogenation reaction of nitrile compounds

A rhodium catalyst and hydrogenation reaction technology, applied in the field of organic chemical raw material synthesis, can solve the problems of harsh reaction conditions and poor selectivity, and achieve the effects of low raw material cost, stable performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation process of the catalyst is as follows:

[0036] (1) Preparation of carbon nanocarriers:

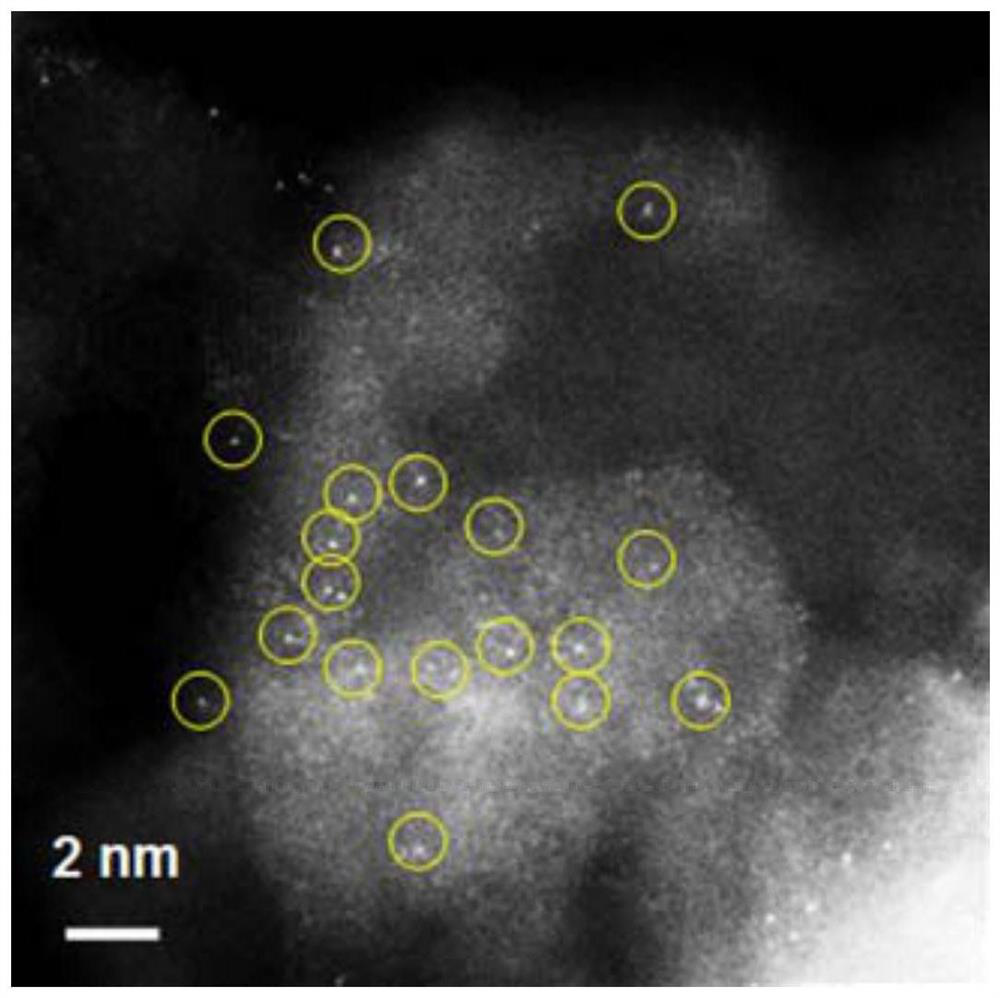

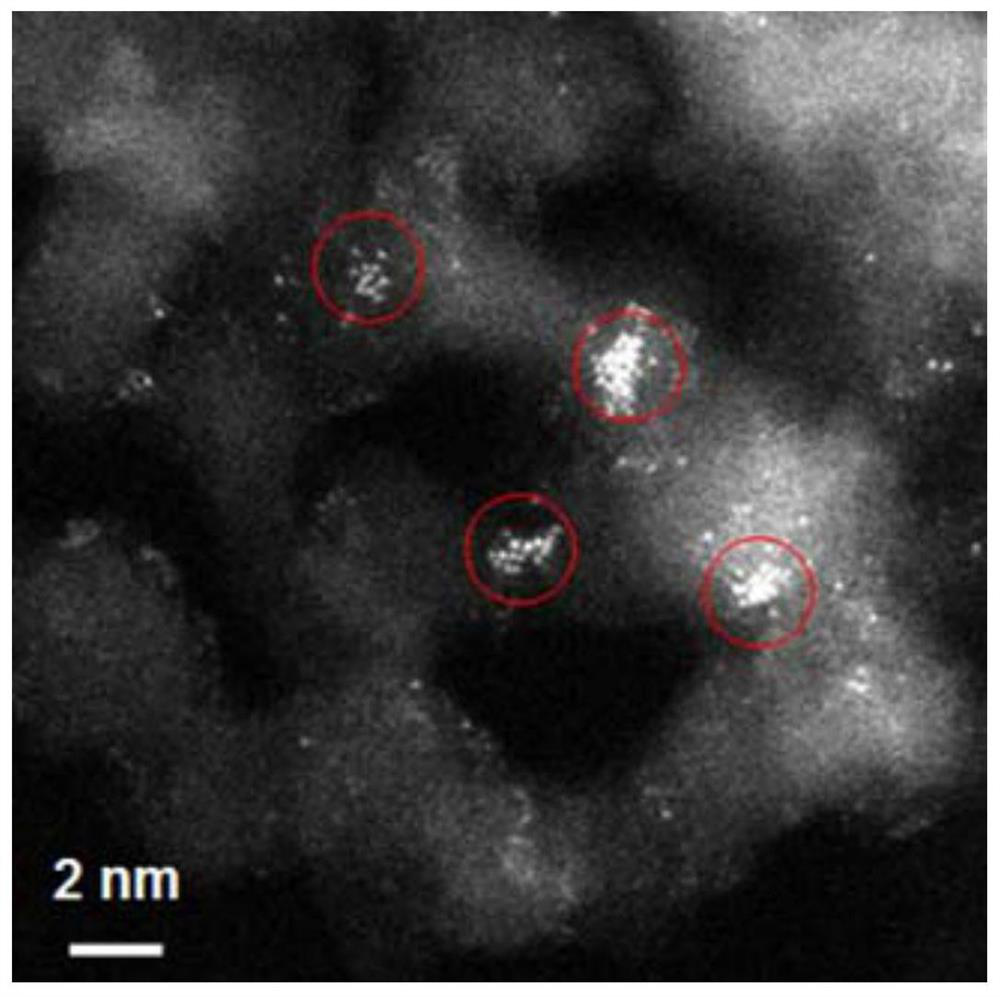

[0037] The nano-diamond raw material is placed in an argon atmosphere at 900-1300° C. and 80-100 mL / min for calcination treatment, and the treatment time is 3-4 hours. After the calcination treatment, a nano-carbon carrier with a core-shell structure is obtained. Such as figure 1 As shown, the prepared carrier has a core-shell structure with nano-diamond as the core and defect-rich graphene as the shell, and a core-shell structure with sp3 carbon core-sp2 carbon shell hybridization.

[0038] (2) The process of deposition precipitation method:

[0039] Add 20-40mL of water into a 100mL round bottom flask, put 200mg of nano-carbon carrier, ultrasonically disperse evenly, and then adjust the pH value to 11-12 with sodium carbonate solution to obtain a nano-carbon carrier dispersion; then prepare 0.01mol / L nitric acid rhodium solution, and calculate the consumption o...

Embodiment 2

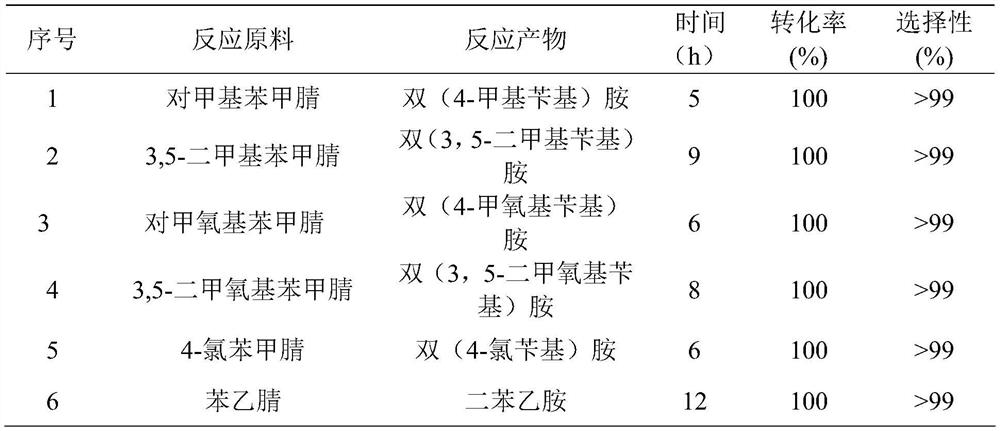

[0041] Weigh 30 mg of Rh / ND@G catalyst (rhodium atomic loading is 0.06 wt%) and disperse it in 10 mL of methanol, and add 0.5 mmol of benzonitrile. Filled with 0.6MPa H 2 , heated to 60°C, and stirred for 4h. The conversion rate of benzonitrile was 99.08%, and the selectivity of dibenzylamine was >99%.

Embodiment 3

[0043] Weigh 30 mg of Rh / ND@G catalyst (rhodium atomic loading is 0.06 wt%) and disperse it in 10 mL of methanol, and add 0.5 mmol of benzonitrile. Filled with 0.6MPa H 2 , warmed up to 40°C, and stirred for 4h. The conversion rate of benzonitrile was 81.41%, and the selectivity of dibenzylamine was >99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com