Low-dielectric low-high-frequency-loss LTCC material and preparation method thereof

A high-frequency loss, ceramic material technology, applied in the field of electronic components, microwave electronic components and ceramic materials, can solve the problems of unstable dielectric constant and high frequency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

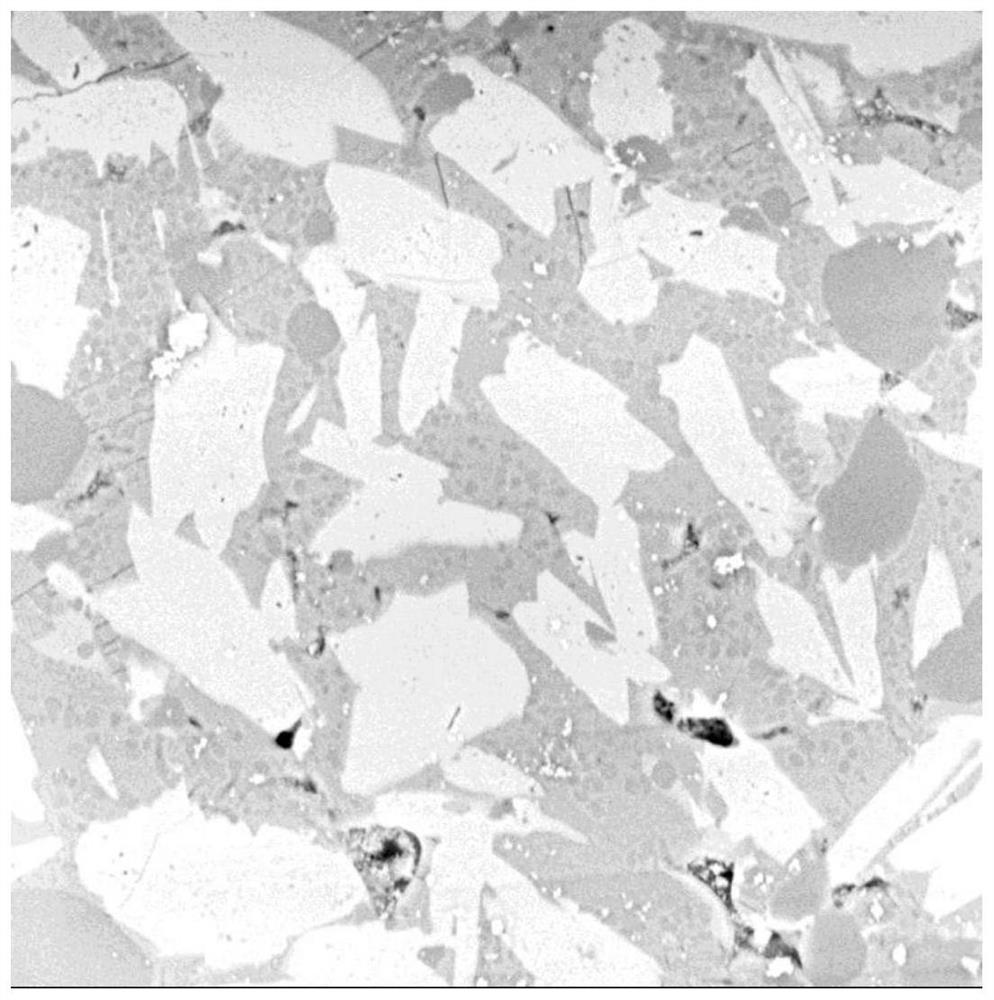

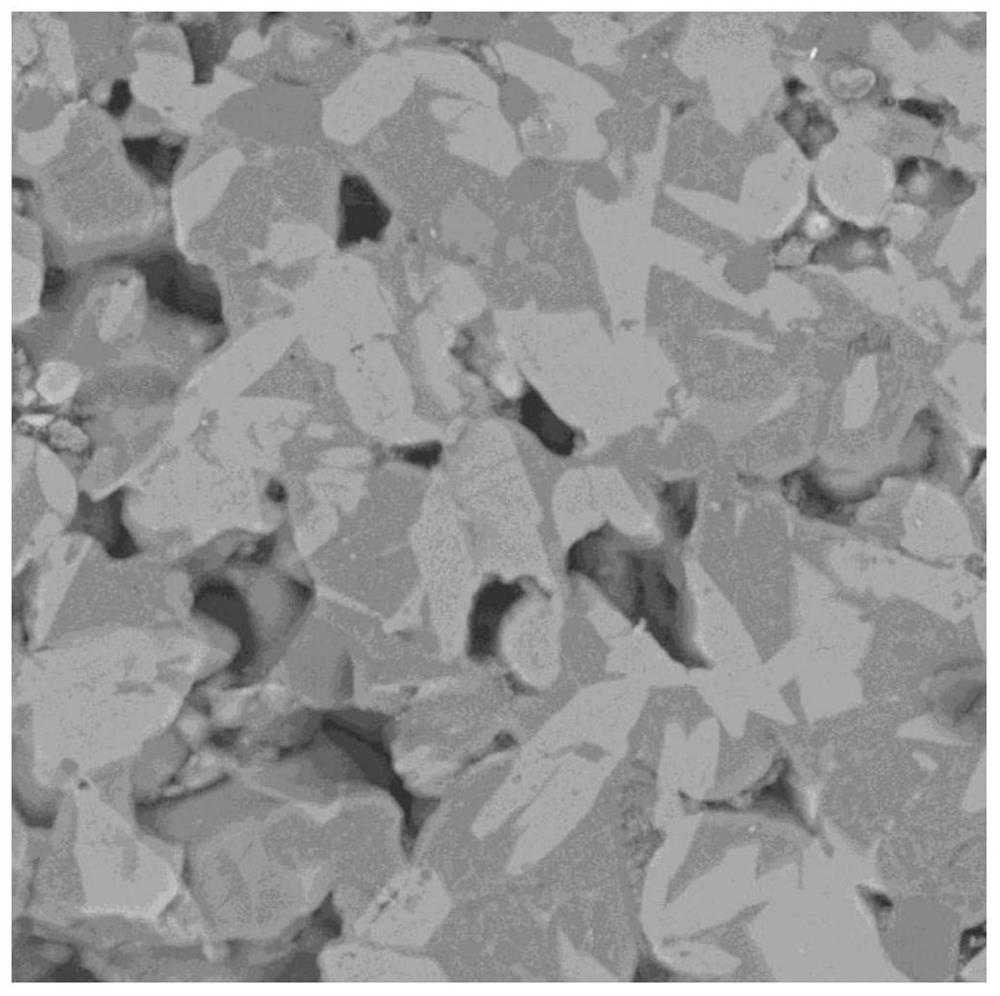

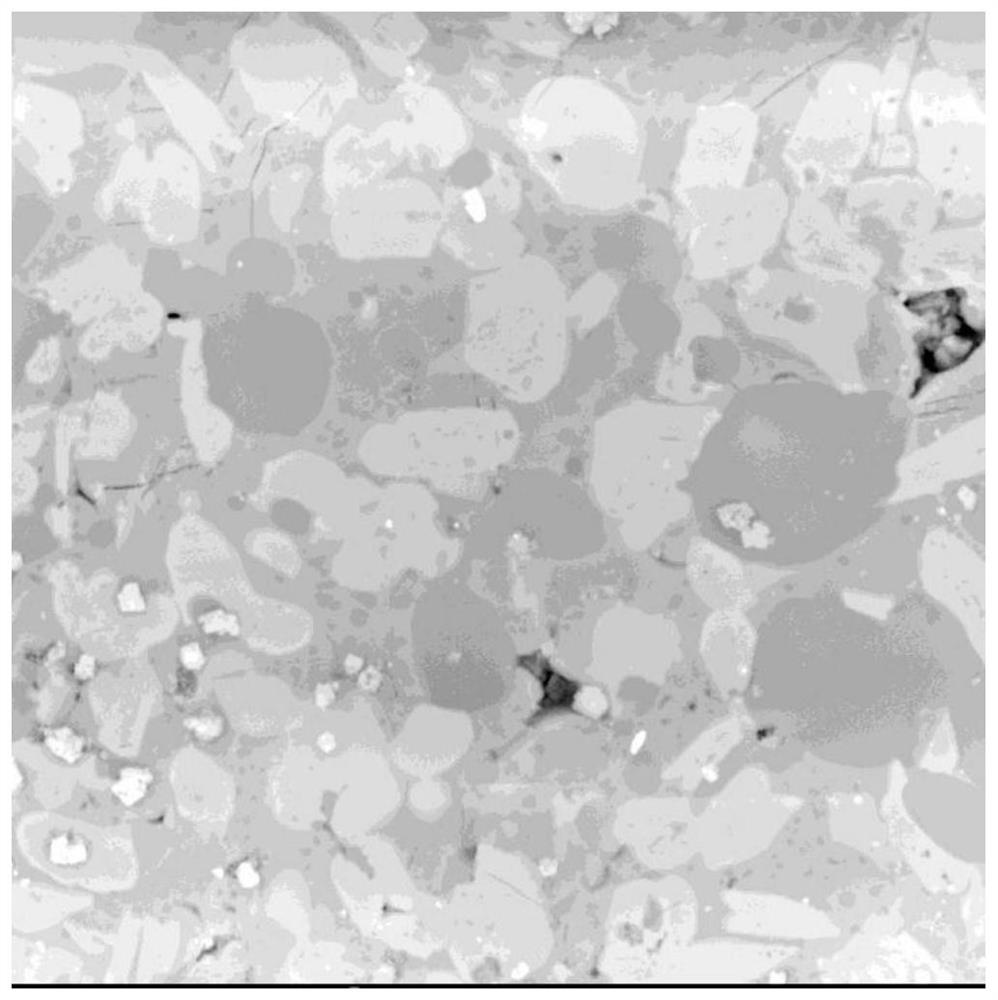

Image

Examples

Embodiment Construction

[0023] The glass formulation of a low-dielectric low-frequency loss LTCC ceramic material is shown in Table 1:

[0024] Table 1 Glass formulation of a low dielectric low high frequency loss LTCC ceramic material

[0025]

[0026]

[0027] In Table 1, SB means borosilicate glass series materials, and GBS means calcium borosilicate glass series materials. SB-7030 is borosilicate glass, composed of 70% silicon dioxide and 30% boron trioxide; SB-7525 is borosilicate glass, composed of 75% silicon dioxide and 25% boron trioxide; SB -8020 is borosilicate glass, which is composed of 80% silicon dioxide and 20% boron trioxide; GBS is calcium borosilicate glass, and GBS-1, GBS-2, GBS-3 are composed of corresponding borosilicate glass The best solution for glass-ceramic systems.

[0028] The main process parameters are as follows:

[0029] Glass smelting: Lime borosilicate glass at 1400°C, melting for 2 hours, borosilicate glass at 1600°C, melting for 2 hours.

[0030] Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com