Blood perfusion resin as well as preparation method and application thereof

A technology of blood perfusion and resin, applied in the field of medical polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

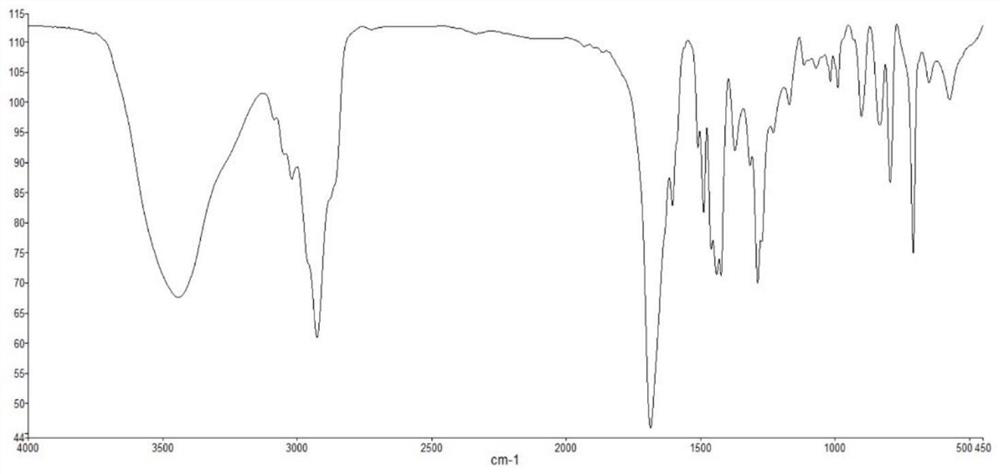

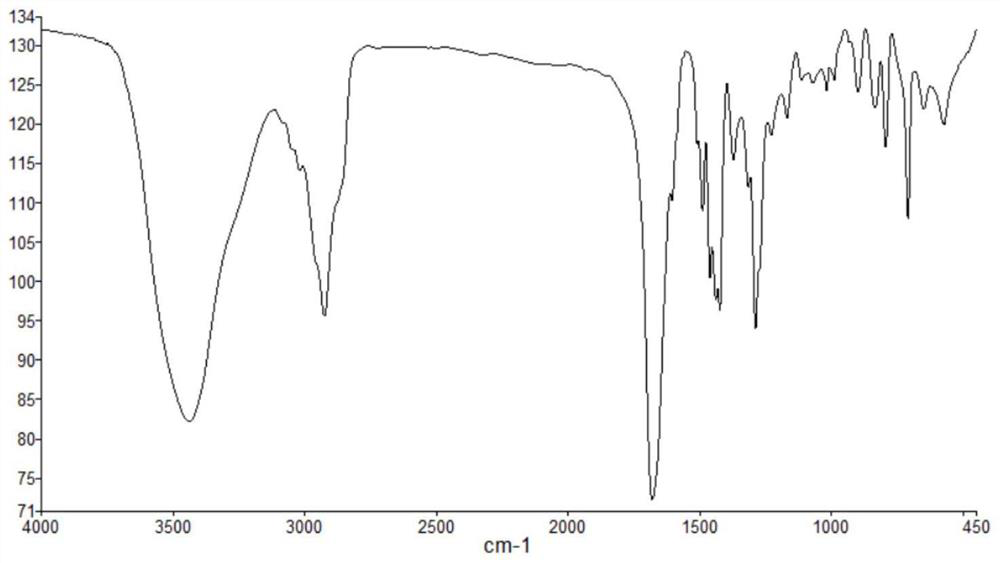

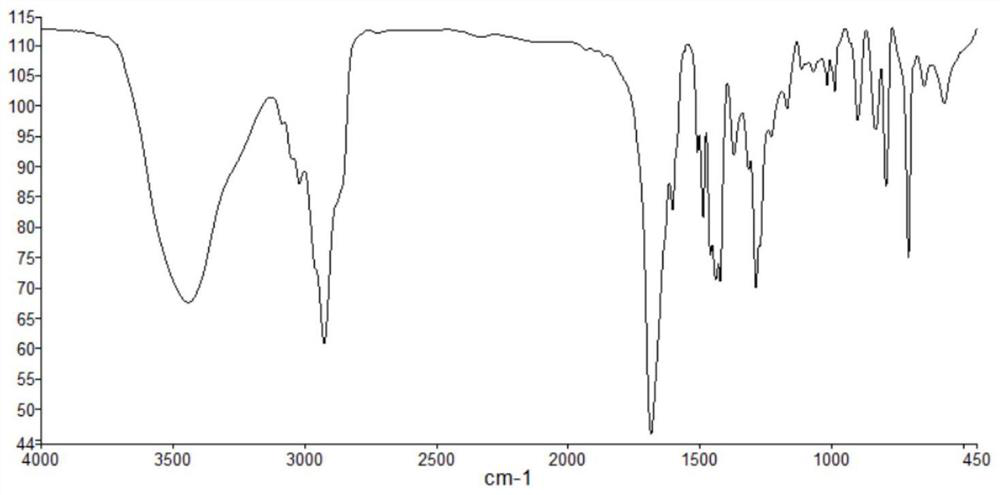

Image

Examples

Embodiment 1

[0062] This embodiment provides a hemoperfusion resin, the preparation method of which is as follows:

[0063] Add the water phase (96g of PVA aqueous solution of 10% by weight, 864g of distilled water) in a 2000ml three-necked flask, stir evenly, and heat up to 40°C. After the water phase is mixed evenly, add the oil phase prepared in advance (80g of DVB80 after deblocking, 240g of toluene, 0.8g of BPO), stir, and heat up at a speed of 5°C / 10min, first to 78°C, and keep warm for 2h; Raise the temperature to 83°C and keep it warm for 3h; finally raise the temperature to 88°C and keep it warm for 3h. After the polymerization is completed, the reaction system is cooled, the resin is packed into a column, the PVA is washed away with hot water, and then the toluene is washed away with ethanol. Put the resin into an oven and dry it at 65°C to obtain the base ball.

[0064] Add 20 g of the above-mentioned base balls into a 1000 ml three-necked flask, mix 64 g of toluene, 16 g of D...

Embodiment 2

[0066] This embodiment provides a hemoperfusion resin, the preparation method of which is as follows:

[0067] Add the water phase (96g of PVA aqueous solution of 10% by weight, 864g of distilled water) in a 2000ml three-necked flask, stir evenly, and heat up to 40°C. After the water phase is mixed evenly, add the oil phase prepared in advance (80g of DVB80 after deblocking, 240g of toluene, 0.8g of BPO), stir, and heat up at a speed of 5°C / 10min, first to 78°C, and keep warm for 2h; Raise the temperature to 83°C and keep it warm for 3h; finally raise the temperature to 88°C and keep it warm for 3h. After the polymerization is completed, the reaction system is cooled, the resin is packed into a column, the PVA is washed away with hot water, and then the toluene is washed away with ethanol. Put the resin into an oven and dry it at 65°C to obtain the base ball.

[0068] Add 20 g of the above-mentioned base balls into a 1000 ml three-necked flask, mix 64 g of toluene, 16 g of D...

Embodiment 3

[0070] This embodiment provides a hemoperfusion resin, the preparation method of which is as follows:

[0071] In a 2000ml there-necked flask, add the water phase (72g of an aqueous solution of 10% by weight of PVA, 648g of distilled water), stir evenly, and heat up to 40°C. After the water phase is mixed evenly, add the oil phase prepared by mixing in advance (DVB80 after deblocking 80g, toluene 240g, BPO 0.8g), adjust the stirring speed, stir, and heat up at a speed of 5°C / 10min, first to 78°C, Keep it warm for 2 hours; then raise the temperature to 83°C and keep it warm for 3 hours; finally raise the temperature to 88°C and keep it warm for 3 hours. After the polymerization is completed, the reaction system is cooled, the resin is packed into a column, the PVA is washed away with hot water, and then the toluene is washed away with ethanol. Put the resin into an oven and dry it at 65°C to obtain the base ball.

[0072] Add 20 g of the above-mentioned base balls into a 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com