Low-carbon steel RH molten steel nitrogen control method and low-carbon steel continuous casting method

A low-carbon steel and molten steel technology, which is applied in the continuous casting of low-carbon steel and the nitrogen control field of low-carbon steel RH molten steel, can solve problems such as difficulty in meeting performance requirements, low product qualification rate, and fluctuations in N content in products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The following steps are used for control in the RH vacuum stage:

[0033] (1) Arrange a furnace of HRB400 molten steel to wash the vacuum tank before the vacuum degassing of 10# steel;

[0034] (2) After the ladle trolley is driven to the processing station, temperature measurement, sampling and oxygen determination of molten steel are carried out;

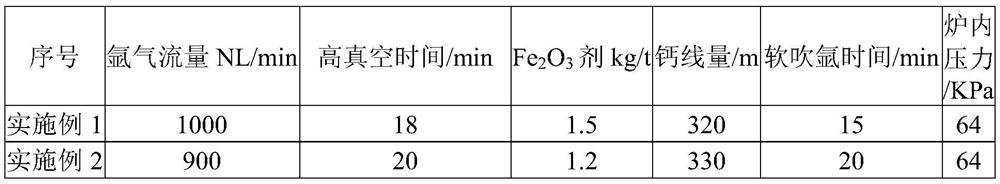

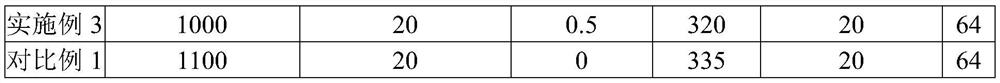

[0035](3) The lifting gas of the RH furnace is set to argon, and the flow rate and the high vacuum time in the furnace are controlled according to Table 2;

[0036] (4) Add a certain amount of Fe to the ladle when vacuuming 2 o 3 agent;

[0037] (5) Feed a certain length of calcium wire and perform soft argon blowing for a certain period of time. The main components of the molten steel of each embodiment before entering the RH vacuum are shown in Table 1; the parameter settings of each embodiment during the RH vacuum process are shown in Table 2;

[0038] It can be seen from Table 3 that in Examples 1 and 2, after soft...

Embodiment 3

[0039] In Example 3, after soft argon blowing for 20 minutes, the content of N element in the measured molten steel composition is 0.0035%, which is higher than the target value. If the content of N element is controlled within the range of 0.002%-0.003%, it needs to be kept at Continuously carry out soft argon blowing under the condition of high vacuum, the total soft argon blowing time is 25min, and keeping high vacuum for a long time increases the difficulty of the process, and the stability of the process is lower than that of Examples 1 and 2. The defective rate becomes high.

[0040] Similarly, in Comparative Example 1, after soft argon blowing for 20 minutes, the content of N element in the measured molten steel composition is 0.0044%, which is higher than the target value. If the content of N element is controlled within the range of 0.002%-0.003%, It is also necessary to keep soft argon blowing under high vacuum conditions. After the total soft argon blowing time is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com