Dyeing and finishing process of cellulose acetate fiber and protein fiber silk fabric

A technology of acetate fiber and protein fiber, applied in the field of dyeing and finishing, can solve the problems of easy color difference and poor dyeing quality of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

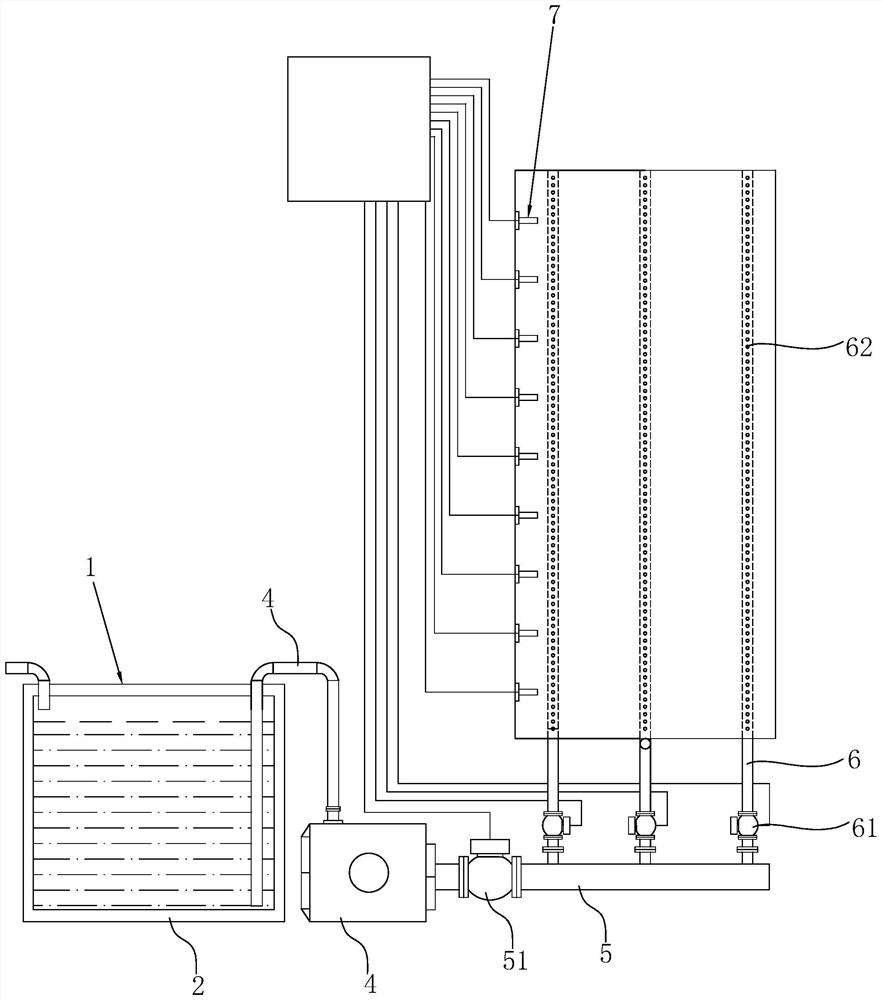

Method used

Image

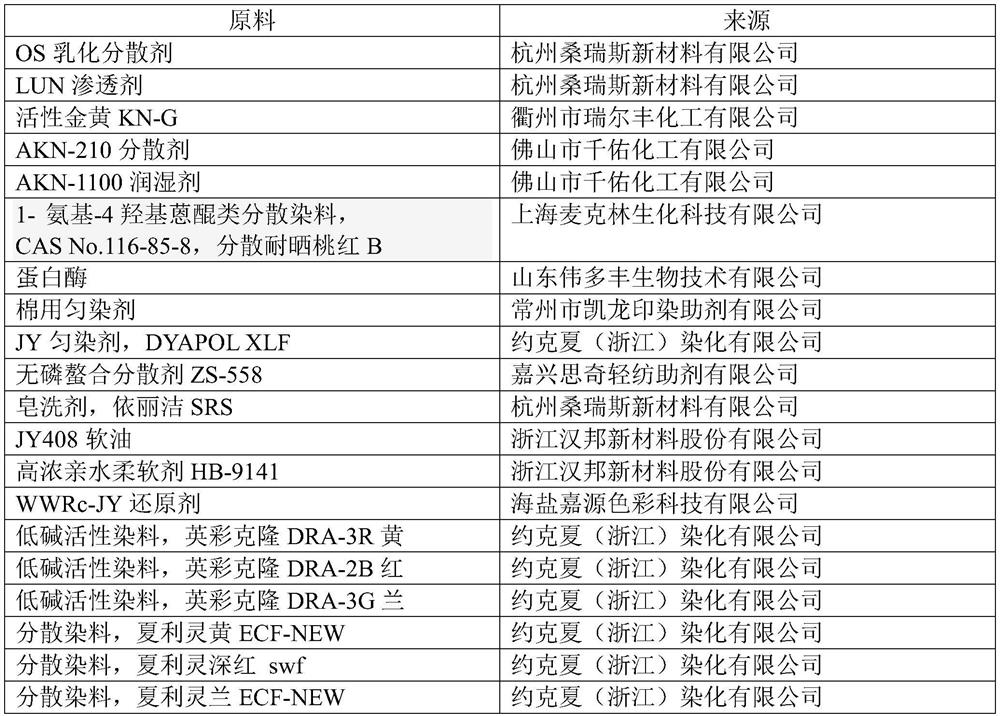

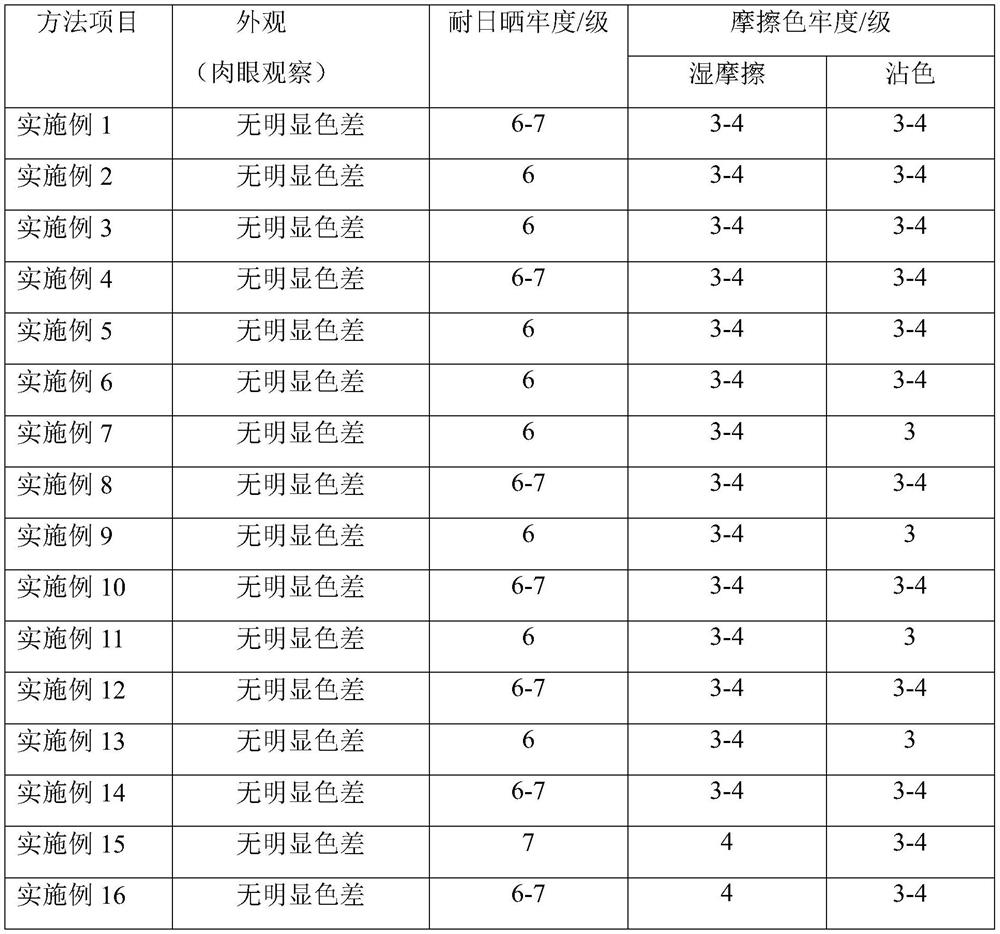

Examples

Embodiment 1

[0078] A kind of dyeing and finishing process of acetate fiber and protein fiber silk fabric disclosed by the application comprises the following steps:

[0079] Step 1, select the acetate silk J3705-2 in raw material 1, first refine the acetate silk J3705-2, put the acetate silk J3705-2 in 0.4g / L protease, 2.0g / L soda ash, 1.0g / l infiltration Soak for 60 minutes in the treatment solution with water temperature of 60°C, pH value of 10, bath ratio of 1:10, and then place the acetate silk J3705-2 fabric in the overflow dyeing machine. The concentration of the auxiliary agent in the overflow dyeing machine is: 2.0g / L OS emulsifying dispersant, 2.0g / L LUN penetrating agent, bath ratio 1:10, water temperature 80°C, soak acetate silk J3705-2 fabric for 30min, wash twice with 40°C deionized water , each cleaning time is 10min, standby;

[0080] Step 2, using the two-bath dyeing method to dye the acetate silk J3705-2 fabric that has completed the pretreatment in step 1. The two-bat...

Embodiment 2

[0099] The difference between Example 2 and Example 1 is that the dyeing formula 1 in Example 1 is replaced by dyeing formula 2: the target dyeing is red, the amount of Yingcai Clone DRA-2B red used is 2%, and the used Charlene deep red swf The dosage is 0.5%.

Embodiment 3

[0101] The difference between Example 3 and Example 1 is that the dyeing formula 1 in Example 1 is replaced by dyeing formula 3: the target dyeing is blue, the amount of Yingcai clone DRA-3G blue used is 2%, and the used Charlene blue ECF -NEW was used in an amount of 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com