Air gap manufacturing method, air gap and electronic equipment

A manufacturing method and technology of electronic equipment, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of reduced mechanical strength of the dielectric layer, unfavorable air gap shape and size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] In the preparation method of the air gap 10 provided by the present invention, after the groove 3 is formed by etching on the first dielectric layer 2, it is not necessary to remove other photoresist layers 5 that have not been removed immediately, and can be directly on the photoresist layer 5. Filling the conductive material in the trench 3 can simplify the process steps and reduce the process cost.

[0063] The height of the air gap is adjusted by adjusting the ratio of the thickness of the photoresist and the dielectric layer, so as to facilitate the control of the height of the air gap 10 .

[0064] Such as Figure 5 to Figure 8 As shown, in some examples, the step of filling the trench 3 with a conductive material and forming the bridging structure 4 includes: sequentially depositing a barrier layer 6 and a seed layer 7 in the trench 3 and on another part of the photoresist layer 5; Fill the conductive material on the seed layer 7; remove the barrier layer 6, the...

specific Embodiment 1

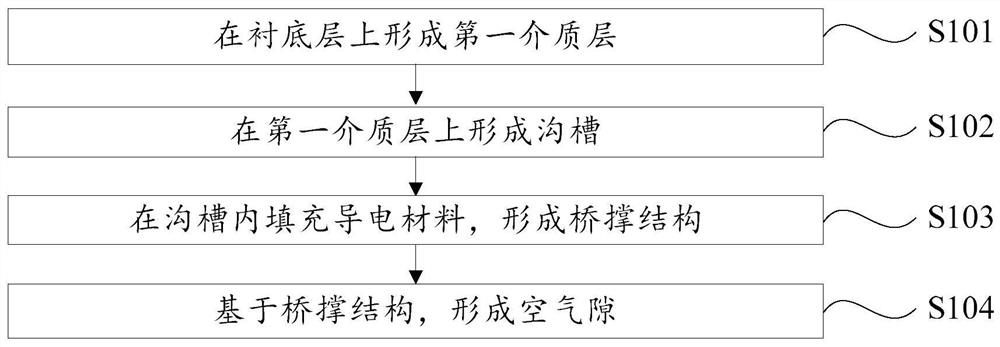

[0087] Such as Figure 2 to Figure 9 with Figure 17 As shown, this embodiment provides a method for manufacturing an air gap, including:

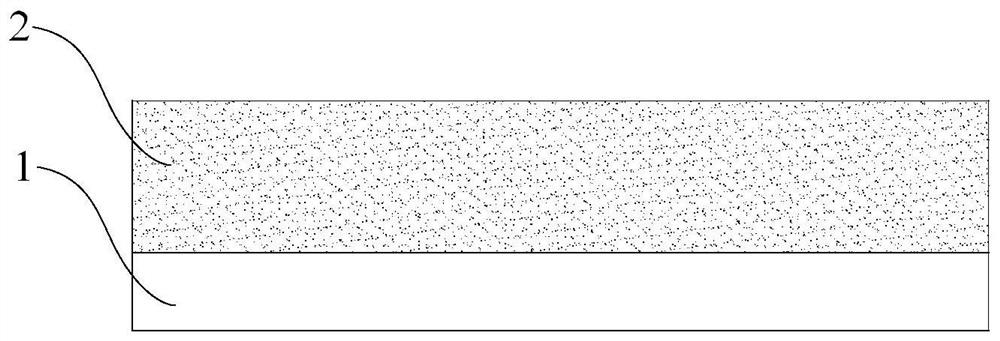

[0088] Step S201: forming a first dielectric layer on the substrate layer;

[0089] Step S201: forming a first dielectric layer on the substrate layer;

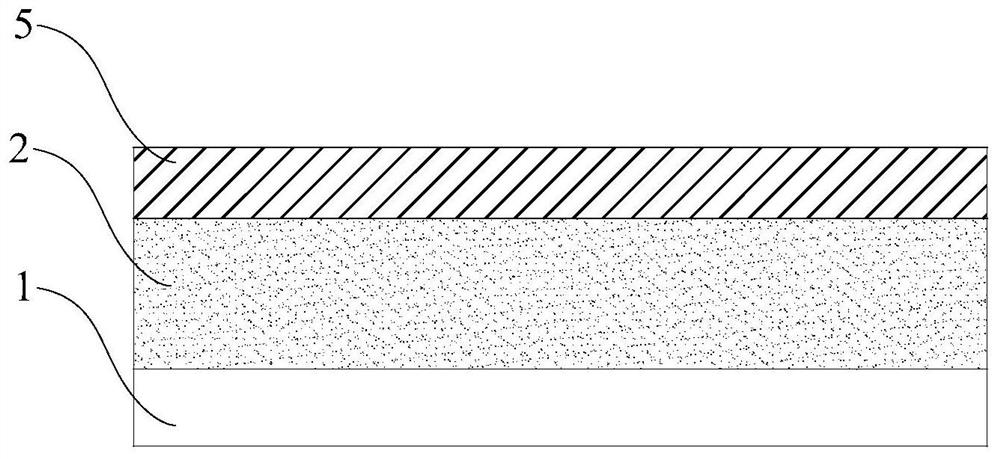

[0090] Step S202: setting a photoresist layer on the first dielectric layer;

[0091] Step S203: removing part of the photoresist layer through an exposure and development process, and removing part of the first dielectric layer through an etching process to form a trench;

[0092] Step S204: filling the trench and another part of the photoresist layer with conductive material;

[0093] Step S205: removing the conductive material on another part of the photoresist layer by etching or chemical mechanical polishing;

[0094] Step S206: Etching another part of the photoresist layer to form a bridge structure;

[0095] Step S207: Depositing a second dielectric layer on the bridging stru...

specific Embodiment 2

[0099] Such as Figure 10 to Figure 16 with Figure 18 As shown, this embodiment provides a method for manufacturing an air gap, including:

[0100] Step S301: forming a first dielectric layer on the substrate layer;

[0101] Step S302: setting a photoresist layer on the first dielectric layer;

[0102] Step S303: Etching part of the photoresist layer and part of the first dielectric layer by a photolithography process to form a trench;

[0103] Step S304: sequentially depositing a barrier layer and a seed layer in the trench and on another part of the photoresist layer;

[0104] Step S305: filling the seed layer with conductive material;

[0105] Step S306: removing the barrier layer, seed layer and conductive material on another part of the photoresist layer by etching or chemical mechanical polishing;

[0106] Step S307: etching another part of the photoresist layer to form a bridge structure;

[0107] Step S308: depositing a liner layer on the bridge structure and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com