Pearlescent pigment dispersing and coating method and polycarbonate plate with pearlescent effect

A polycarbonate and pearlescent pigment technology, applied in the direction of fibrous fillers, dyed polymer organic compounds, etc., can solve the problems of complex, oxide layer wear, particle size wear, poor appearance, narrow application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

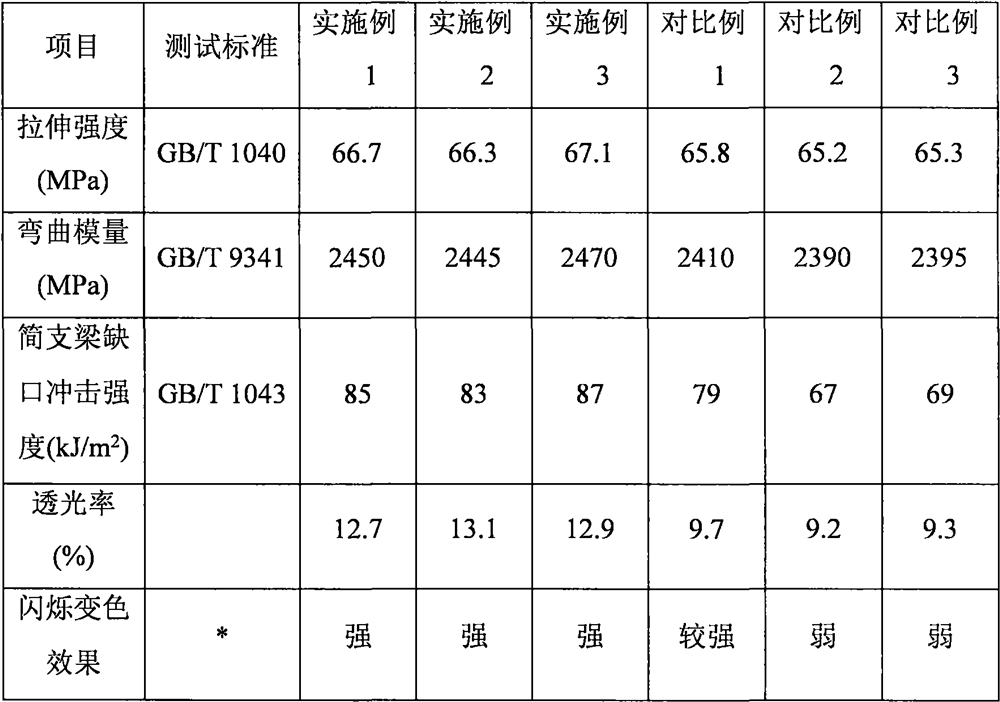

Examples

Embodiment 1

[0031] A coating method for pearlescent pigments, comprising the steps of:

[0032] 1) Dissolve 100g of polycarbonate particles (Zhetie Dafeng Company 02-10R) in 2000g of dichloroethane at room temperature in a 3L three-necked flask equipped with mechanical stirring and ultrasonic waves to make a solution;

[0033] 2) 100g of pearlescent pigment (brand name Pyrisma T30-00, Merck, Germany) is added under mechanical stirring at room temperature in the dichloroethane solution of polycarbonate, stirred and dispersed to obtain pearlescent pigment polycarbonate dichloride Chloroethane mixture;

[0034] 3) Add 200ml of absolute ethanol dropwise at room temperature at a rate of 20ml / min to the stirring pearlescent pigment polycarbonate dichloroethane mixture, the polycarbonate is precipitated and the flake pigment is coated to obtain a polycarbonate coated Pearlescent pigments;

[0035] 4) Filtrating to obtain the polycarbonate-coated pearlescent pigment and drying to obtain a powde...

Embodiment 2

[0039] A coating method for pearlescent pigments, comprising the steps of:

[0040] 1) Dissolve 100g of polycarbonate particles (SC-1100R of South Korea's Samsung Company) in 1000g of chloroform at room temperature in a 3L three-necked flask equipped with mechanical stirring and ultrasonic waves to make a solution;

[0041] 2) 300g pearlescent pigment (brand name Pyrisma T10-08, Merck of Germany), 100g pearlescent pigment (brand Iriodin 7217, Merck of Germany) was added to the chloroform solution of polycarbonate under mechanical stirring at room temperature In, stir and disperse to obtain the pearlescent pigment polycarbonate trichloromethane mixed solution;

[0042] 3) Add 100ml of methanol dropwise at room temperature at a rate of 20ml / min to the stirring pearlescent pigment polycarbonate chloroform mixture, the polycarbonate precipitates and coats the flaky pigment to obtain a polycarbonate-coated pearlescent pigment ;

[0043] 4) Filtrating to obtain the polycarbonate-c...

Embodiment 3

[0047] A coating method for pearlescent pigments, comprising the steps of:

[0048] 1) 45g of polycarbonate powder (brand CLARNATE 2100, Yantai Wanhua) was dissolved in 1800g of dichloromethane at room temperature in a 3L three-necked flask equipped with mechanical stirring and ultrasonic waves to make a solution;

[0049] 2) Add 5g of pearlescent pigment (designation YZ9126, Shanghai Yunzhu Company) under mechanical stirring at room temperature into the methylene chloride solution of polycarbonate, stir and disperse to obtain the pearlescent pigment polycarbonate dichloromethane mixed solution ;

[0050] 3) Add 200ml of isopropanol dropwise at room temperature at a rate of 20ml / min to the stirring pearlescent pigment polycarbonate methylene chloride mixture, the polycarbonate precipitates and coats the flaky pigment to obtain a polycarbonate-coated Pearlescent pigments;

[0051] 4) Filtrating to obtain the polycarbonate-coated pearlescent pigment and drying to obtain a powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com