Blasting method for complex rock masses of open pit coal mine in arid area

A technology for open-pit coal mines and arid areas, applied in the direction of blasting, etc., can solve problems such as safety facilities and equipment hazards in mining sites, impacts on mining and transportation safety operations, and inability to evenly distribute blasting energy. The loading and transportation are safe and convenient, and the effect of prolonging the crushing action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

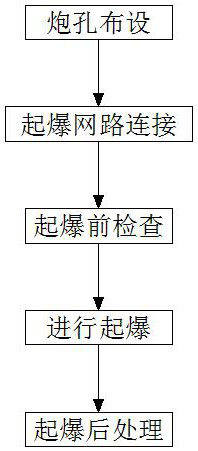

[0030] see figure 1 , this embodiment provides a method for blasting complex rock masses in an open-pit coal mine in an arid area, including the following steps:

[0031] Step 1: Layout of blastholes

[0032] Firstly, carry out on-site inspection of the bench blasting horizontal mining section in the open-pit mining area to be blasted, and analyze the lithological changes along the strike and inclination of the mining area, and then determine the blasting parameters and charge structure according to the analysis results, and then lay out the Mark the blasting hole position corresponding to the line spacing, and then drill the blast hole at the marked position. When laying out the marked blast hole position, lay out 5 rows of holes each time, and the number of blast holes in each row is 7, and ensure that the blasting area is free along the positive direction. The number of blastholes in the surface direction is more than the number of blastholes in the lateral free surface di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com