Novel microalgae having high loliolide productivity

A technology of ryegrass lactones and Scenedesmus, applied in unicellular algae, microorganism-based methods, medical raw materials derived from algae, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

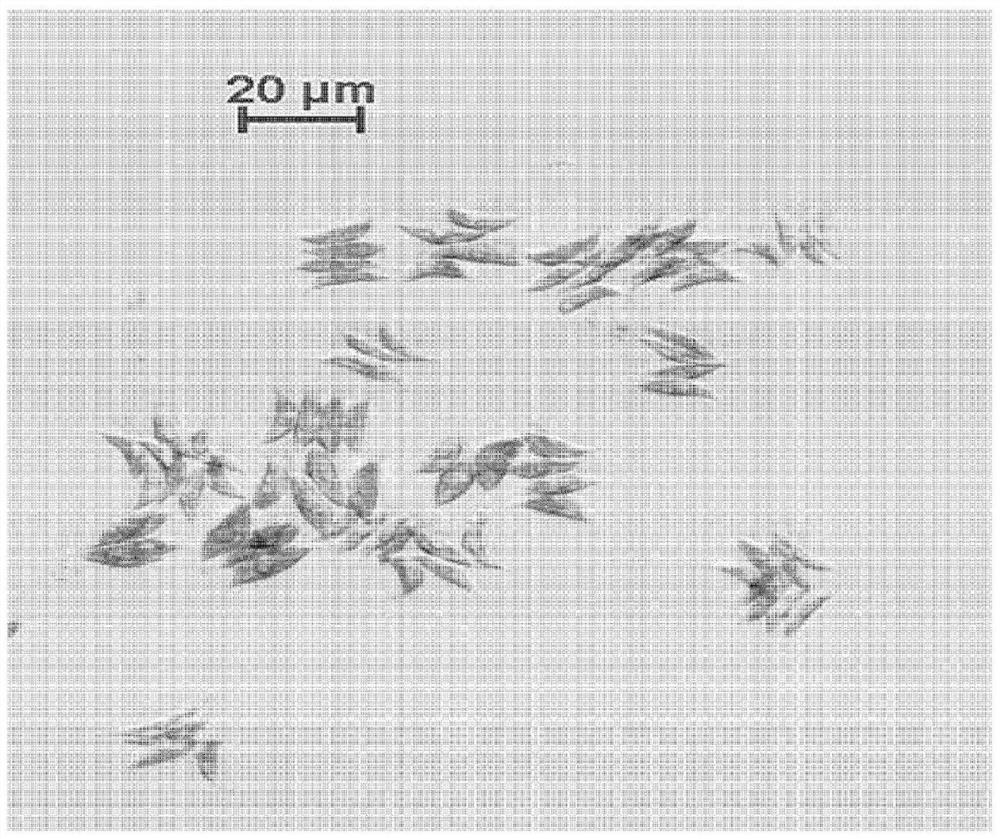

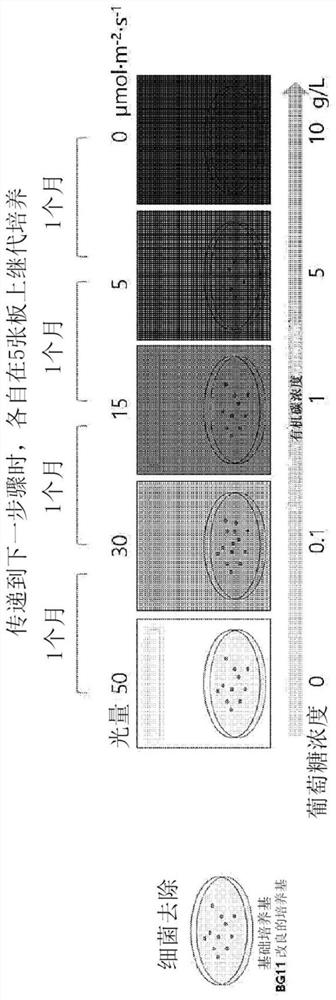

[0105] [Example 1] Improvement of Scenedesmus HS4 Microalgae

[0106] In order to produce a new type of microalgae that does not depend on light and has high efficiency in the dissimilation of organic carbon, and to guide the adaptive evolution of light and organic carbon, an improved microalgae of the genus Scenedesmus HS4 was prepared. As a mother plant for improvement, Scenedesmus genus JD052 microalgae (accession number KCTC1899P), which is one of the microalgae capable of producing ryegrass lactone, was used. Hydrosphere isolated microalgae. The Microalgae of the genus Scenedesmus JD052 was used as an object, and the organic carbon was supplied while changing the concentration, and the light irradiation amount was changed for cultivation. In order to develop microalgae that can grow even in the absence of light, the microalgae are cultivated in a conventional light culture medium for microalgae, wherein the method of gradually reducing the amount of light exposure by inc...

Embodiment 2

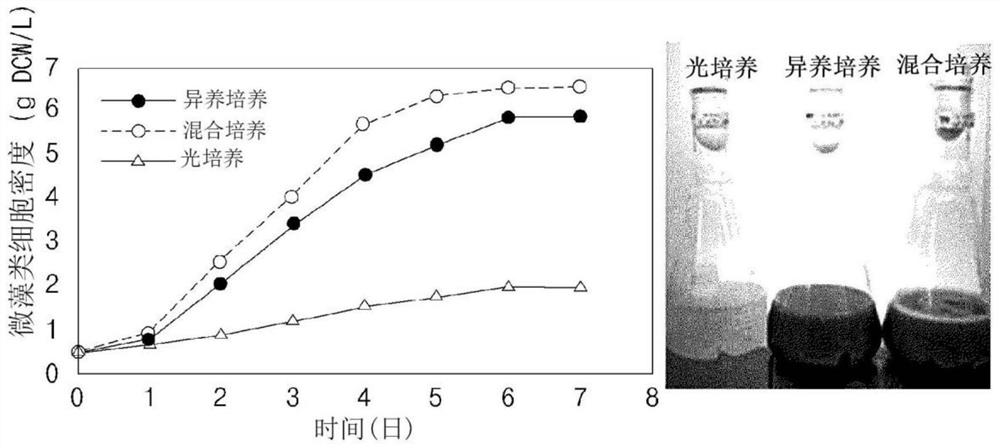

[0111] [Example 2] Confirmation of the growth curve according to the culture conditions

[0112] In order to confirm the growth of the improved Scenedesmus genus HS4 microalgae ensured by the above-mentioned Example 1 according to the culture conditions, the Scenedesmus genus HS4 was used as the object, according to heterotrophic culture (heterotrophic culture, culture conditions that provide organic carbon), The microalgae were cultured by setting different culture conditions for photoautotrophic culture (culture conditions for providing light) and mixed culture (for culture conditions for providing both organic carbon and light).

[0113]Specifically, in the case of heterotrophic culture conditions first, 10 g / L of glucose and 1 g / L of yeast extract were added to the sterilized medium (Ph7.1) composed of the components in Table 1. The culture solution (350 ml) was used to culture the Scenedesmus sp. HS4 of the present invention in a 1 L flask at 25° C. for seven days. The i...

Embodiment 3

[0117] [Example 3] Type analysis of active ingredients

[0118] In order to confirm what the active ingredient produced by Scenedesmus HS4 of the present invention is, 55 g of the extract was obtained from 1000 g of the culture solution of the microalgae, and the ingredient was analyzed. The cultured microalgae are centrifuged to remove the supernatant of the culture solution to obtain only the microalgae cells, which are freeze-dried at -70° C. to remove water. Then, cells were extracted from the freeze-dried biomass using ethyl acetate, and after the cells were extracted, the organic solvent was distilled using a rotary vacuum evaporator to obtain an extract. The extract sample is dissolved in a solvent, subjected to silica gel column chromatography (silica gel column Chromatography) and high performance liquid chromatography (HPLC, high performance liquid chromatography) for fractional distillation, and concentrates the active fraction in the fractions , purified by prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com