Low-grade gold ore separation and tailing-free utilization process

A low-grade, gold ore technology, applied in sorting, solid separation, grain processing, etc., can solve the problems of unreasonable crushing and grading process, low sorting efficiency, and difficult production practice, so as to reduce the amount of system compliance and improve the total Recovery rate and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Experimental study on gold waste rock in a certain place

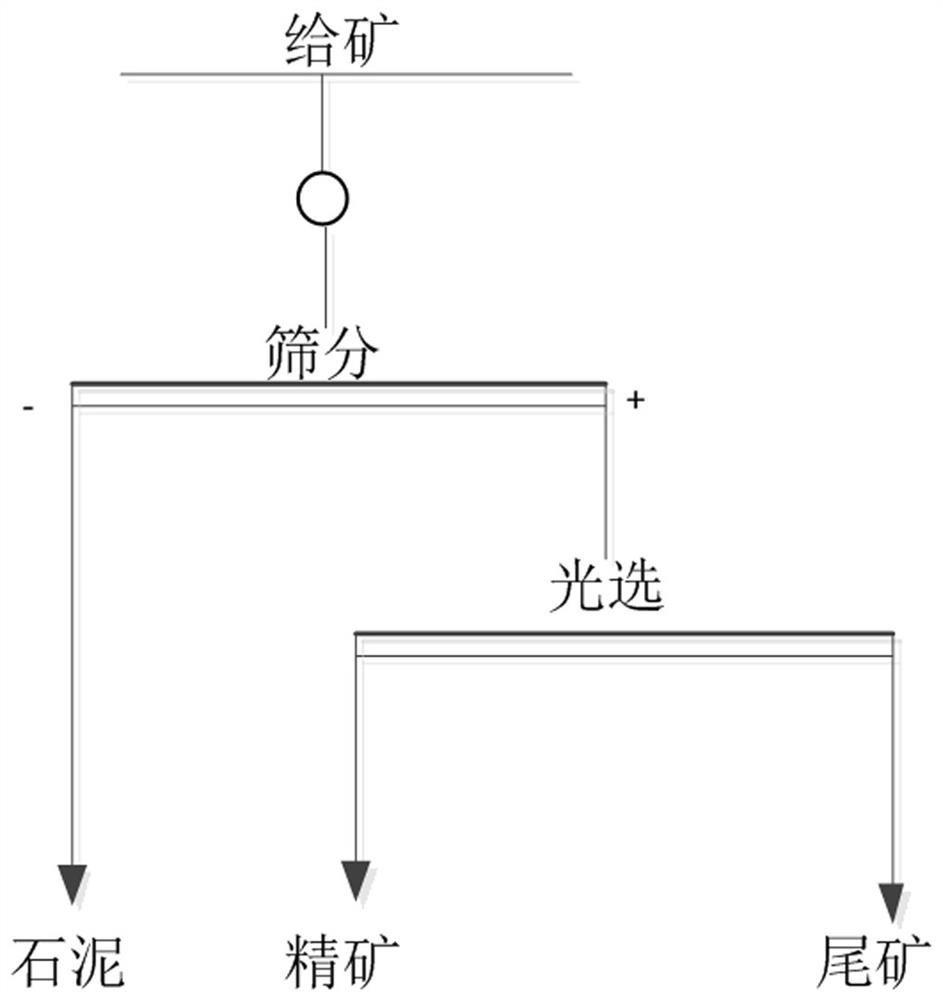

[0074] Such as Figure 5 In the example of the closed-circuit process for re-crushing of light-separated concentrate, raw ore is roughly crushed to obtain products of about 0-120mm in size, and the content of fine-grained grades is relatively small;

[0075] Obtain rough concentrate and rough tailings through a stage of light separation;

[0076] The coarse concentrate passes through the 10mm sieve after medium and fine crushing, and the product on the sieve passes through the second stage of optical separation; the second stage of optical separation concentrate is the final concentrate, and enters the grinding and gravity separation system; the second stage of optical separation concentrate is returned to the medium and fine crushing, and the second stage of optical separation tailings is tailings 1; The particle size of tailings 1 is above 10mm;

[0077] Coarse tailings pass through a 30mm sieve after enteri...

Embodiment 2

[0089] Technical renovation of crushing system in a gold beneficiation plant

[0090] Such as Figure 9 As shown, the raw ore enters the coarse sieve after coarse crushing, the product on the sieve enters the medium crushing, the medium crushing product enters the fine sieve, the product on the fine sieve enters the fine crushing, and the fine crushing product returns to the fine sieve; the fine sieve and the coarse sieve Combined into crushed products.

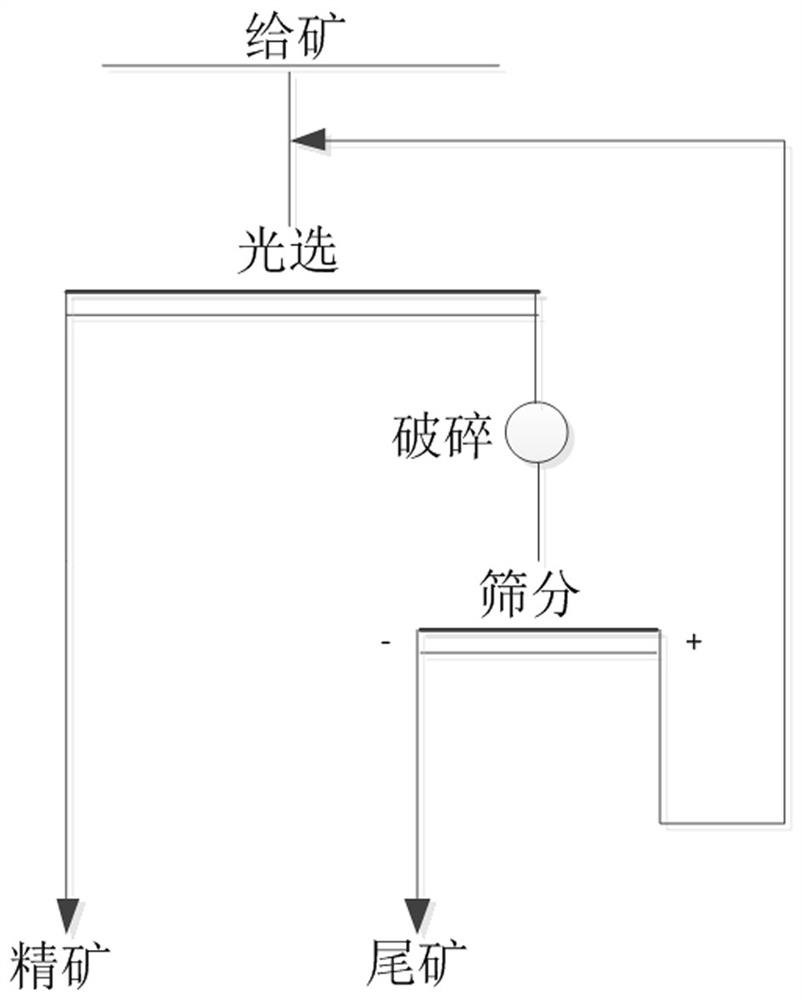

[0091] The mining enterprise has a large stockpile of gold waste rocks. In order to be able to recycle and treat this solid waste without tailings, the process is transformed. The process flow chart after transformation is as follows Figure 10 Shown:

[0092] The raw ore enters the 10mm coarse screen after coarse crushing, the product on the screen enters the medium crushing, the medium crushing product enters the fine screen, and the product on the fine screen enters the optical separation; the optical separation tailings...

Embodiment 3

[0097] Intelligent photoselection test of gold waste rock in a certain area

[0098] In a gold mine, a survey was carried out, and three types of waste rocks, high-grade waste rock, medium-grade waste rock, and low-grade waste rock were collected, and intelligent optical separation tests were carried out respectively.

[0099] , rough selection test

[0100] In this test, high-grade, medium-grade and low-grade ores were used for intelligent sorting machine sorting. The test results are shown in Tables 4-6.

[0101] Table 4 Separation test of high-grade gold waste rock

[0102]

[0103] Grade gold waste rock sorting test in Table 5

[0104]

[0105] Table 6 Separation test of low-grade gold waste rock

[0106]

[0107] It can be seen from the above table that there are certain differences in the sorting indicators of gold waste rocks of different grades. Generally, as the grade of gold waste rocks decreases, the total recovery rate also decreases.

[0108] , fine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com