A kind of preparation method of cellulose composite porous imprinted adsorbent

A technology of imprinted adsorption and cellulose, which is applied in the direction of selective adsorption, chemical instruments and methods, ion exchange, etc., to achieve the effect of favorable adsorption capacity, excellent selection and recognition performance, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

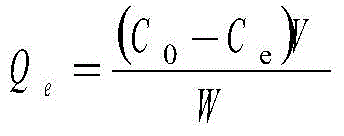

Method used

Image

Examples

Embodiment 1

[0033] 1. A preparation method of cellulose composite porous imprinted adsorbent, carried out according to the following steps:

[0034] (1) Preparation of NCCs:

[0035] Medical absorbent cotton and 50% concentrated sulfuric acid solution were mixed at a ratio of 1g:60ml, stirred at 50°C for 3 hours, the resulting NCCs were washed with a large amount of deionized water and dialyzed to neutrality, and the obtained colloidal suspension was refrigerated at 5°C for later use.

[0036] (2) Preparation of MIPFs

[0037] Dissolve the template molecule 4-NP and the functional monomer AM in the NCCs colloidal suspension, wherein the ratio of 4-NP, AM to the suspension is 0.5mmol: 10mmol: 3ml, and place it in the dark for 5h to form a pre-assembled Solution, add crosslinking agent MBAM, surfactant Tween 85, initiator potassium persulfate, ultrasonic 1min, form water phase (w), the dosage ratio of pre-assembly solution, MBAM, Tween 85, potassium persulfate is 3ml: 1mmol: 0.1ml: 0.02g;...

Embodiment 2

[0047] 1. A preparation method of cellulose composite porous imprinted adsorbent, carried out according to the following steps:

[0048] (1) Preparation of NCCs:

[0049] Medical absorbent cotton was mixed with 70% concentrated sulfuric acid solution at a ratio of 3g:100ml, stirred at 70°C for 6h, the resulting NCCs were washed with a large amount of deionized water and dialyzed to neutrality, and the obtained colloidal suspension was refrigerated at 5°C for later use.

[0050] (2) Preparation of MIPFs

[0051] Dissolve the template molecule 4-NP and the functional monomer AM in the NCCs colloidal suspension, wherein the ratio of 4-NP, AM to the suspension is 0.5mmol: 20mmol: 6ml, and place it in the dark for 10h to form a pre-assembled Solution, add cross-linking agent MBAM, surfactant Tween 85, initiator potassium persulfate, ultrasonic 1min, form water phase (w), the dosage ratio of pre-assembly solution, MBAM, Tween 85, potassium persulfate is 6ml: 4mmol: 0.3ml: 0.04g; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com