Waterborne polyurethane resin and low-temperature-resistant waterborne PVC primer

A water-based polyurethane and primer technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of being unable to use at low temperatures, achieve good adhesion, scientific and simple formula, and good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

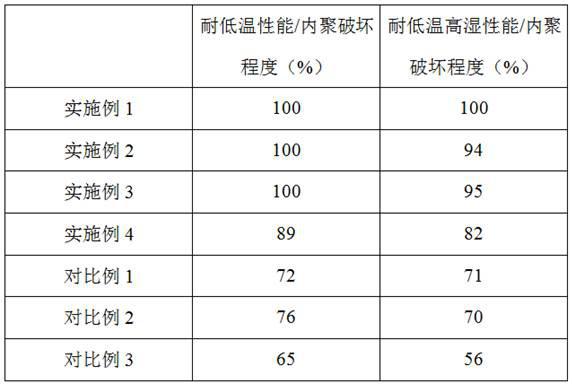

Examples

Embodiment 1

[0028] A water-based polyurethane resin, in parts by mass, comprising: 20 parts of isophorone diisocyanate, 15 parts of hydroxyl-terminated polybutadiene, 15 parts of acetone, 10 parts of castor oil modified polyester polyol, 8 parts of 1, 4-butanediol, 4 parts of dimethylethanolamine, 5 parts of 2,2-dimethylolpropionic acid, 0.05 parts of organic bismuth, 60 parts of deionized water.

[0029] In this example, the hydroxyl-terminated polybutadiene was purchased from Nippon Soda Co., Ltd., under the brand name JP-200.

[0030] In this example, the castor oil-modified polyester polyol was purchased from Ventruce in the United States under the brand name D2000.

[0031] The preparation method of described aqueous polyurethane resin, comprises the following steps:

[0032] Add hydroxyl-terminated polybutadiene, castor oil modified polyester polyol, and 1,4-butanediol into the reaction kettle, raise the temperature to 130°C, vacuum dehydrate for 2 hours, and cool down to 50°C unde...

Embodiment 2

[0036] A water-based polyurethane resin, in parts by mass, comprising: 15 parts of isophorone diisocyanate, 6 parts of hydroxyl-terminated polybutadiene, 5 parts of acetone, 5 parts of castor oil modified polyester polyol, 3 parts of 1, 4-butanediol, 2 parts of dimethylethanolamine, 0.5 part of 2,2-dimethylolpropionic acid, 0.05 part of organic bismuth, 50 parts of deionized water.

[0037] In this example, the hydroxyl-terminated polybutadiene was purchased from Nippon Soda Co., Ltd., under the brand name JP-100.

[0038] In this example, the castor oil-modified polyester polyol was purchased from Ventruce, USA, under the brand name D1000.

[0039] The preparation method of described aqueous polyurethane resin, comprises the following steps:

[0040] Add hydroxyl-terminated polybutadiene, castor oil-modified polyester polyol, and 1,4-butanediol into the reactor, raise the temperature to 130°C, vacuum dehydrate for 2 hours, and cool down to 50°C under the protection of an ine...

Embodiment 3

[0043] A water-based polyurethane resin, in parts by mass, comprising: 18 parts of isophorone diisocyanate, 12 parts of hydroxyl-terminated polybutadiene, 10 parts of acetone, 8 parts of castor oil modified polyester polyol, 5 parts of 1, 4-butanediol, 2.5 parts of dimethylethanolamine, 3 parts of 2,2-dimethylolpropionic acid, 0.05 part of organic bismuth, 55 parts of deionized water.

[0044] In this example, the hydroxyl-terminated polybutadiene was purchased from Nippon Soda Co., Ltd., under the brand name GI-2000.

[0045] In this example, the castor oil-modified polyester polyol was purchased from Ventruce, USA, under the brand name D1000.

[0046] The preparation method of described aqueous polyurethane resin, comprises the following steps:

[0047] Add hydroxyl-terminated polybutadiene, castor oil-modified polyester polyol, and 1,4-butanediol into the reactor, raise the temperature to 130°C, vacuum dehydrate for 2 hours, and cool down to 50°C under the protection of an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com