Bismuth electroplating solution and method for preparing bismuth film through electroplating

An electroplating solution and thin film technology, applied in circuits, semiconductor devices, etc., can solve problems such as strong cyanide toxicity, and achieve the effects of strong electrical conductivity, good binding force, high dispersion and covering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

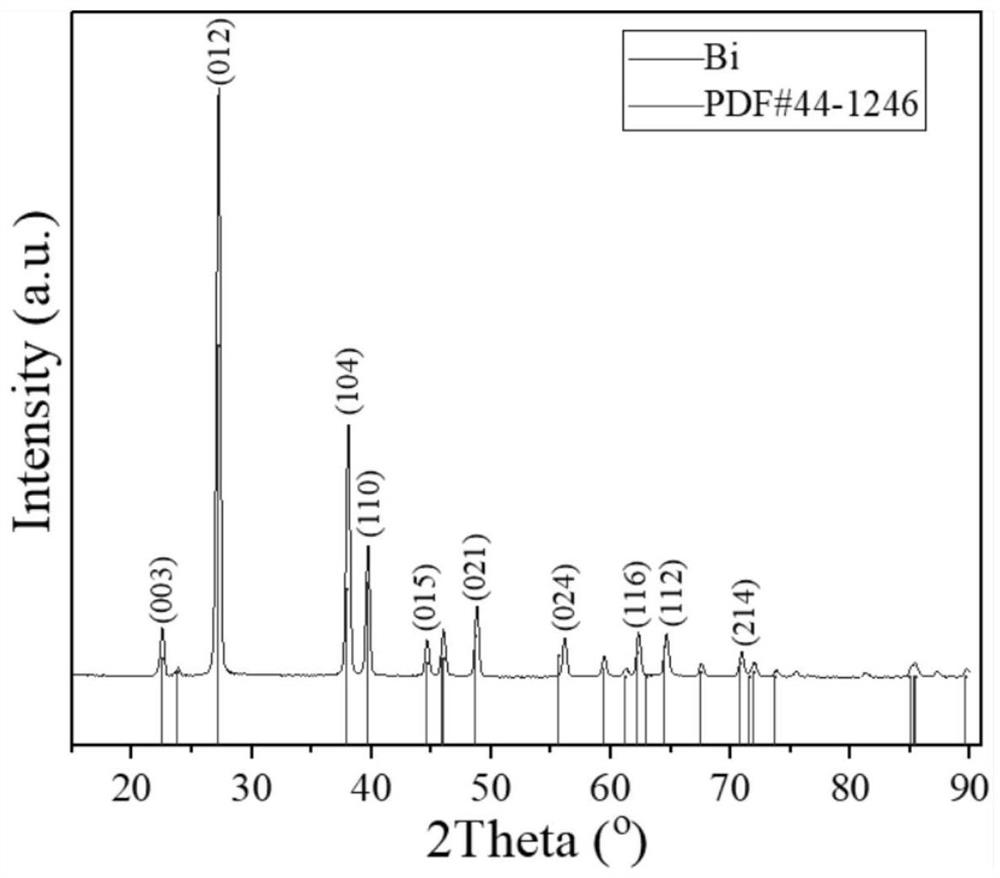

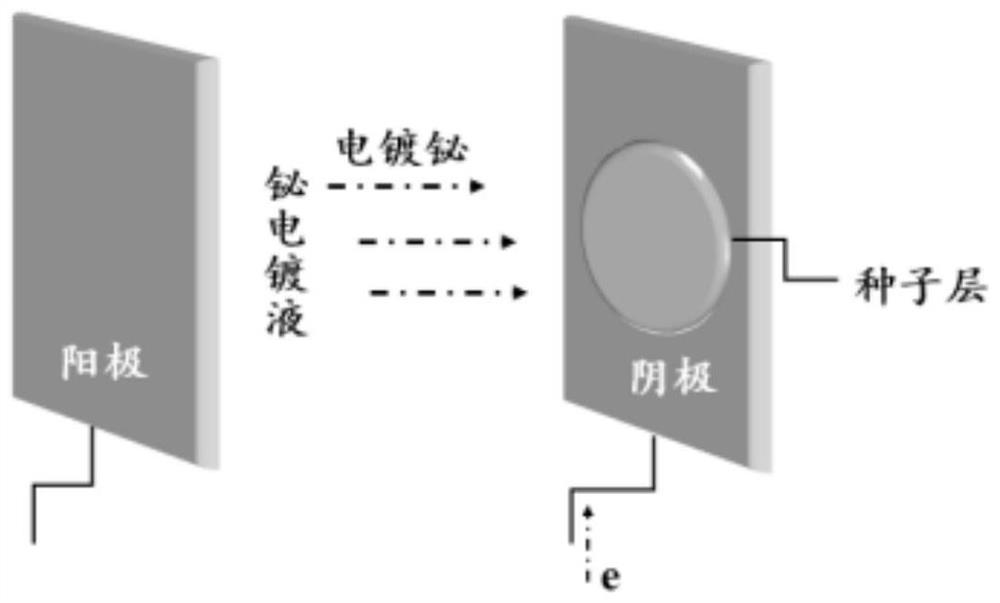

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0019] In present embodiment example 1, use above-mentioned electroplating solution to plate bismuth thin film to comprise the following steps

[0020] Preparation of electroplating solution; preparation of bismuth plating electroplating solution includes the following reagent components: potassium hydroxide or potassium nitrate or potassium chloride 0.5mol / L, nitric acid 2.0mol / L, glycerin 1.5mol / L, L-tartaric acid 0.8mol / L, Bismuth nitrate pentahydrate is 0.3mol / L, and the rest is deionized water.

[0021] Plating preparation process

[0022] Prepare the cathode seed layer: after depositing 5nm Ti on the silicon wafer, continue to deposit 80nm Au to prepare the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com