Flame-retardant low-release material layer-stranded optical cable and preparation method thereof

A technology of optical cable and flame-retardant tape, which is applied in the field of flame-retardant low-emission layer twisted optical cable and its preparation, to achieve the effects of improving resistance strength, improving bending performance, and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

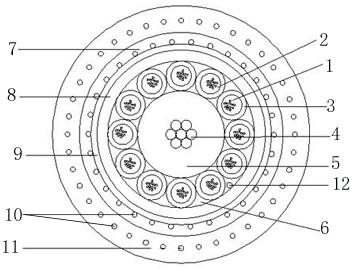

[0030] Such as figure 1 As shown, the present invention is a flame-retardant low-emission layer stranded optical cable, which includes a strengthening structure located in the center of the cable. The strengthening structure is composed of a strengthening element 4 and a flame-retardant cushion 5 extruded outside the strengthening element. ; The outer edge of the strengthening structure surrounds a plurality of optical fiber units, the optical fiber unit includes a loose tube 3, and a plurality of optical fibers 1 are arranged in the loose tube, and the loose tube The filler 2 in the tube is filled with the optical fiber; the plurality of optical fiber units are wrapped with a metal composite tape 8, and the gap between the plurality of optical fiber units and the metal composite tape is filled with a cable core filler 6 and an open cable 12; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com