Semiconductor laser integrated chip and preparation method thereof

A technology of integrating chips and lasers, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems affecting the use scene and scope of semiconductor lasers, difficult to decipher laser chips, and large thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

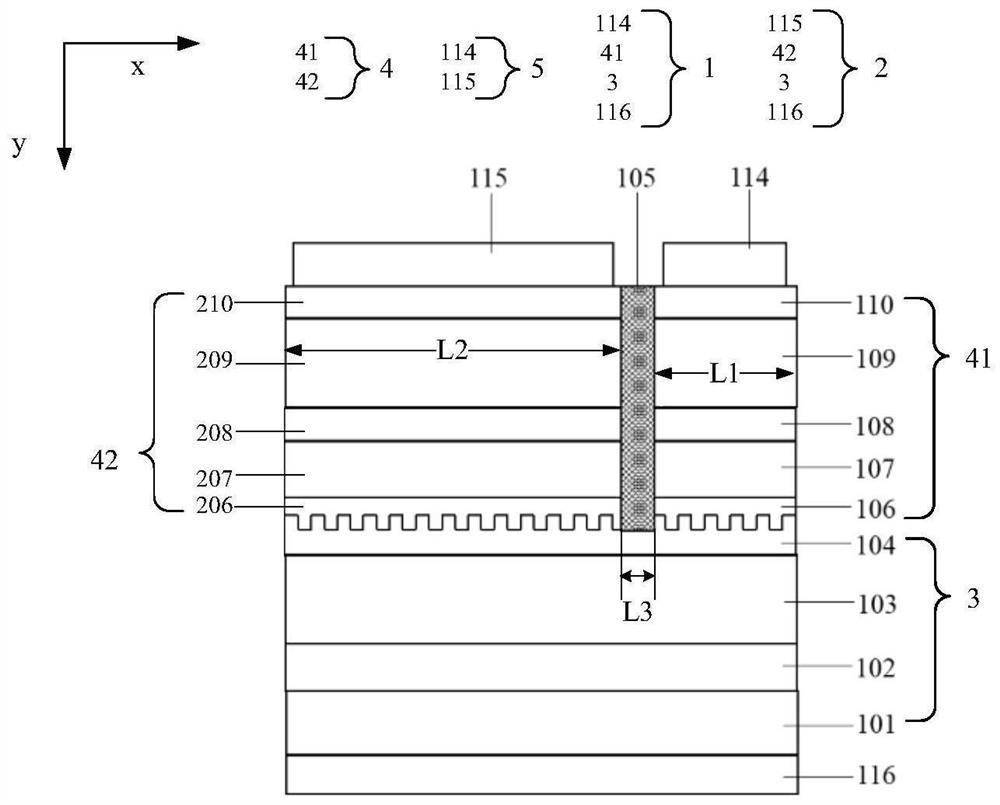

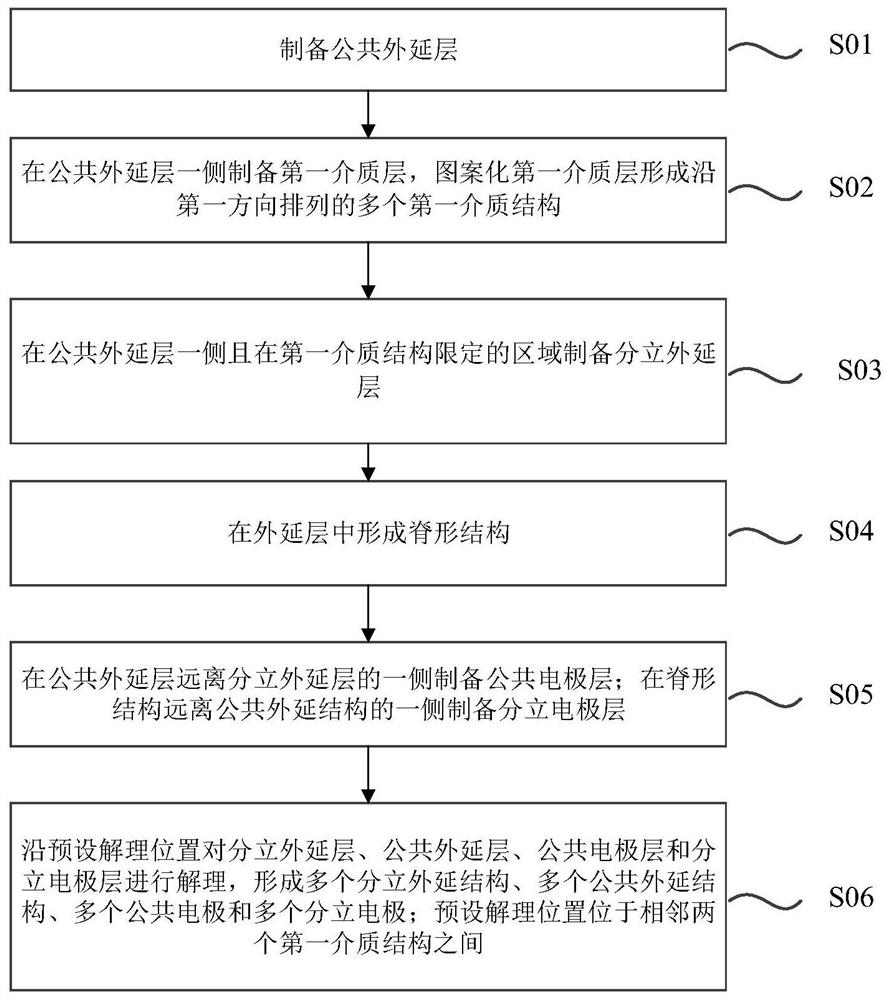

[0072] Embodiment of the present invention provides a semiconductor laser integrated chips, it can be used to prepare the production of DFB lasers. figure 1 A cross-sectional schematic view of an integrated semiconductor laser chip structure according to an embodiment of the present invention. like figure 1 , The semiconductor laser chip integrated laser emitting unit comprises a laser detection unit 1 and 2; integrated semiconductor laser chip further comprising: a common epitaxial structure 3; a first dielectric structure 3 side of the common epitaxial structure 105 and discrete epitaxial structure 4; discrete the epitaxial structure comprises 4 mutually independent first discrete structure 41 and the second discrete epitaxial epitaxial structure 42; both sides in a first direction x, the first discrete structure 41 and the second discrete epitaxial epitaxial structure 42 are respectively located in the first dielectric structure 105 ; second direction y, one side of the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com