Photocatalytic water treatment device

A water treatment device and photocatalytic technology, applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of redundant waste gas and sludge, long consumption time of bacteria, large volume, etc. , achieve the effect of reducing COD and VOC, high redox efficiency and increasing reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

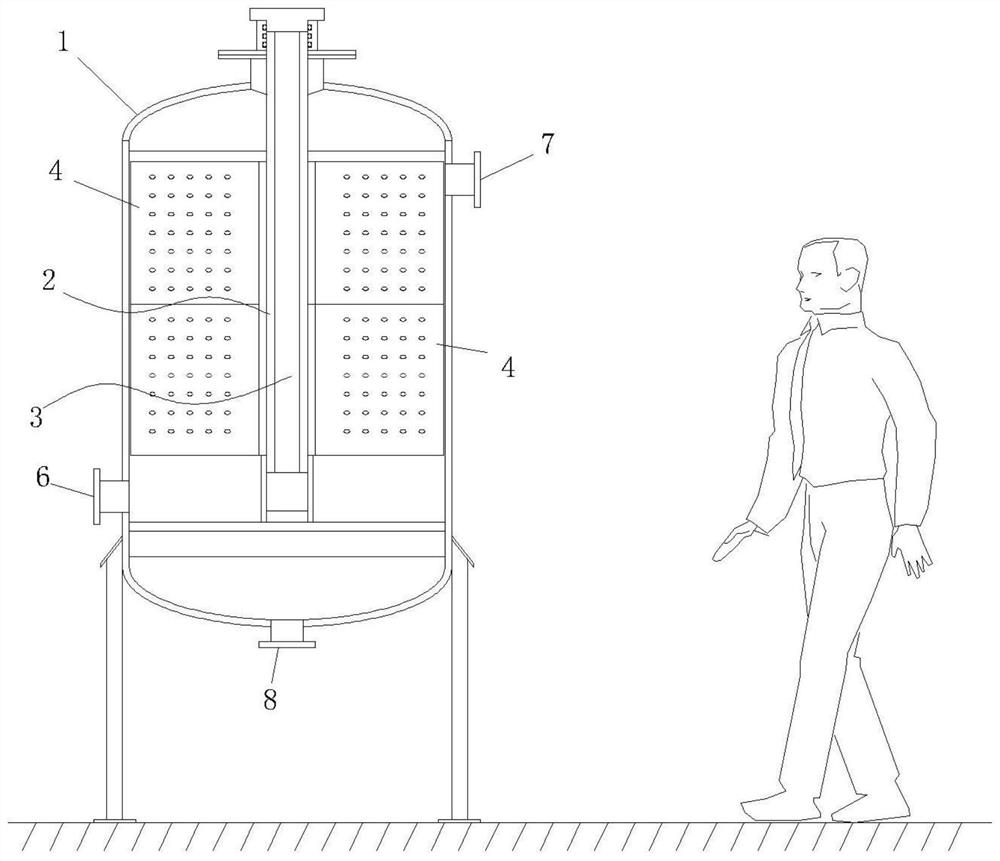

[0028] This embodiment aims to provide a water treatment device using photocatalytic technology. A reaction unit is added to the original tank body 1, and the original simple biological sedimentation tank is improved, so that the process of water treatment overcomes the limitations of the prior art. Defects, Maximize Benefits.

[0029] The method of use in this embodiment is as follows: connect the sewage water supply pipe to the water inlet 6 of the tank body 1, and supply water to the tank body 1 through the water inlet 6; the sewage in the tank body 1 drives the filler 5 to gradually submerge the permeable partition 4; Turn on the ultraviolet lamp 3, and the ultraviolet light causes the titanium dioxide nano-coating on the filler 5 and the water-permeable partition 4 to produce an oxidation-reduction reaction; open the water outlet 7 on the top of the tank body 1, and discharge the treated water with a better cleanliness in the upper layer; when it is necessary to clean Whe...

Embodiment 2

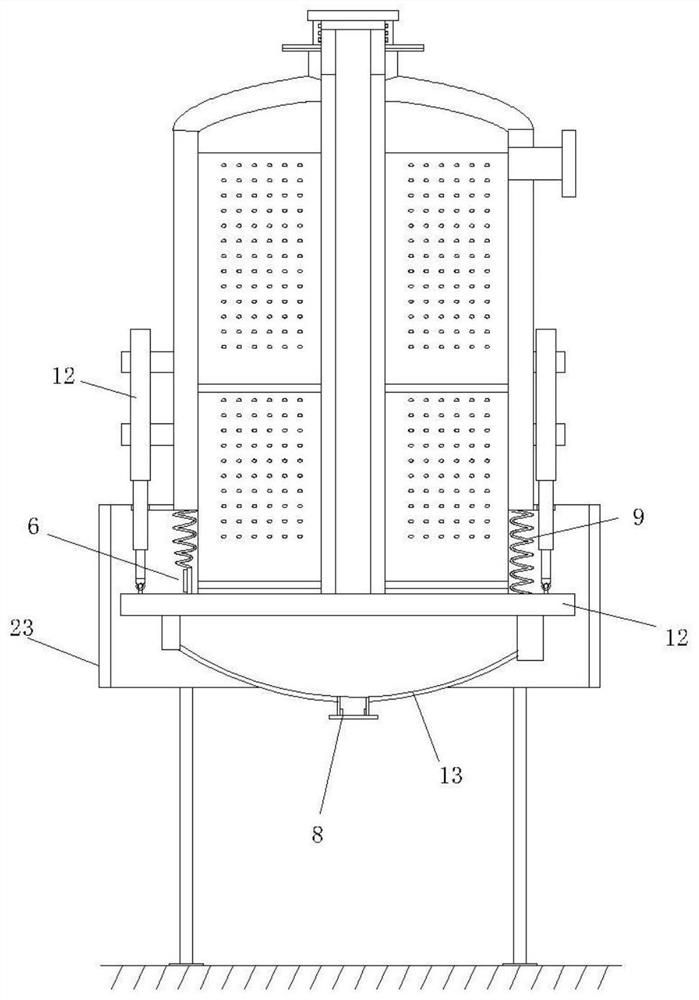

[0035] In the first embodiment, since the space in the tank body 1 is fixed, and most of the sewage contains sludge, the sludge in the tank is getting bigger and bigger, and the space is getting smaller and smaller. This embodiment is made on the basis of the first embodiment, and the purpose is to solve the above-mentioned problems. The measures taken are to add a space expansion mechanism on the basis of the tank body 1 and the reaction unit.

[0036] The operation process of this embodiment is as follows: when the space needs to be expanded, start the lifting device 12 to drive the fixed seat 11 down, and the soft multi-layer composite water-proof cloth 9 is gradually stretched from the contracted state; when the soft multi-layer composite water-proof cloth 9 Fixing seat 11 stops descending when being fully straightened.

[0037] The circulation interval is located between the water inlet 6 and the water-permeable partition 4 , and since the water inlet 6 is set on the wate...

Embodiment 3

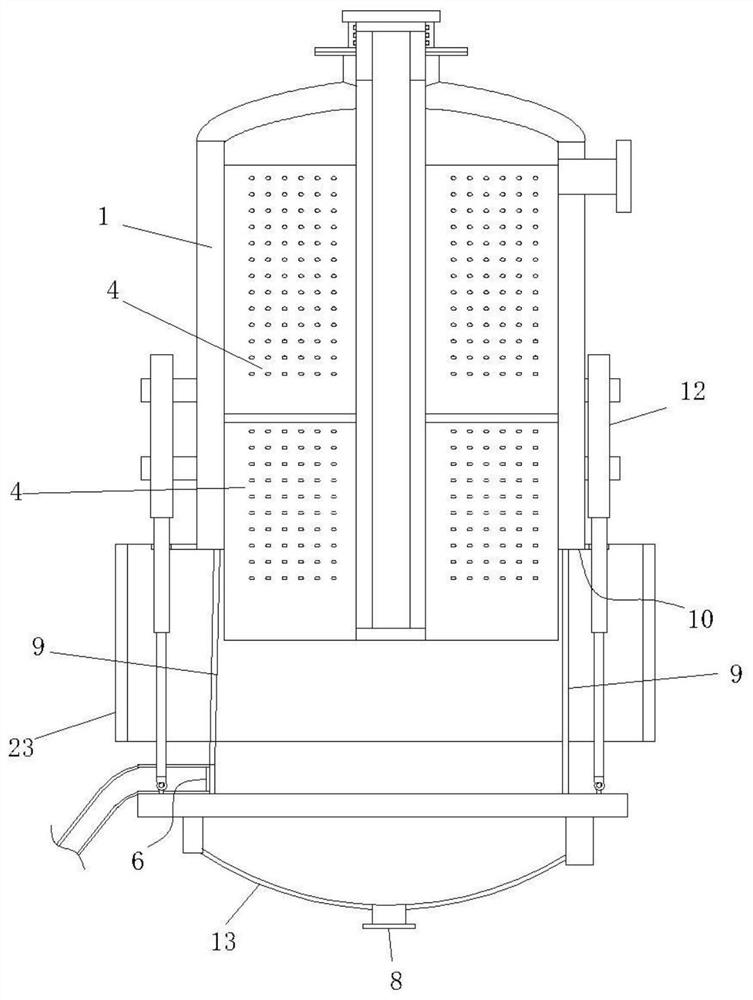

[0045] This embodiment is made on the basis of the second embodiment to provide better safety protection for the space expansion mechanism and avoid uncontrolled fall of the space expansion mechanism when the lifting device 12 fails.

[0046] The operating principle of this embodiment is as follows: when the fixed seat 11 descends, it drives the sliding sleeve 21 to move downward, and the limit mechanism located in the fixed sleeve 20 shrinks as the sliding sleeve 21 descends. The reaction force is applied to buffer the decline of the space expansion mechanism.

[0047] The bottom of the tank body 1 is also provided with a telescopic support leg 19, which is composed of a fixed sleeve 20 and a sliding sleeve 21 worn together, the fixed sleeve 20 is fixed on the ground, and the sliding sleeve 21 is fixed on the ground. At the bottom of the ring-shaped fixed seat 11, the telescopic leg 19 is provided with a limiting mechanism, which is used to limit the maximum contraction strok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com