UV printing ink and preparation method thereof

An ink, epoxy acrylate technology, applied in the direction of ink, household appliances, applications, etc., can solve the problems of affecting the curing effect, high ink viscosity, insufficient adhesion and flexibility, etc., to promote hardening rate, fast curing rate, curing The effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

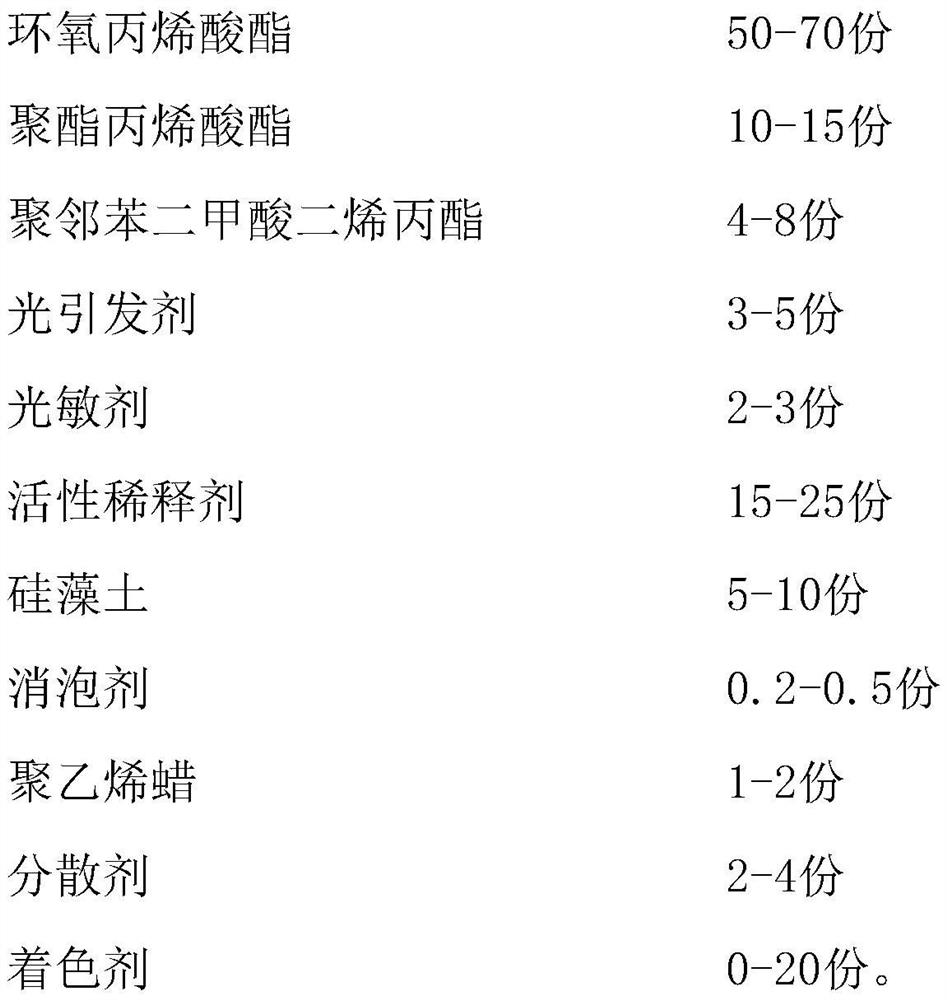

[0036] A kind of UV printing ink, comprises the raw material of following weight part:

[0037]

[0038] The preparation method of described epoxy acrylate comprises the steps:

[0039] (R1), get 100 parts of epoxy resin, 35 parts of acrylic acid, 0.03 part of hydroquinone, 0.08 part of triethylamine and 20 parts of vinyl alkoxysilane oligomers by weight, for subsequent use;

[0040] (R2), after mixing acrylic acid, hydroquinone and triethylamine, a mixed solution is obtained;

[0041] (R3) Stir the epoxy resin and heat it up to 95°C, then continue to drop the mixed solution, and react at a temperature of 115°C for 3 hours to obtain a semi-finished product;

[0042] (R4), add vinyl alkoxy silane oligomer to the semi-finished product, then stir and react at 80°C for 1.5h under the catalysis of organotin, distill under reduced pressure, then wash, dry and filter to obtain epoxy acrylic acid ester.

[0043] The epoxy resin is EP-12; the vinyl alkoxy silane oligomer is selec...

Embodiment 2

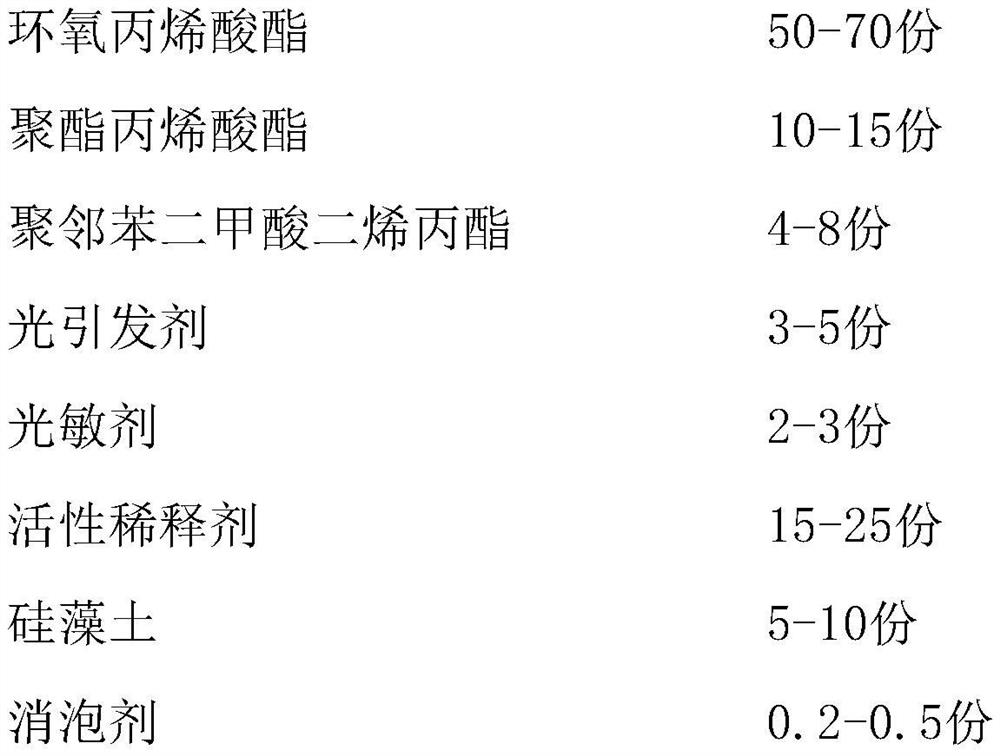

[0055] A kind of UV printing ink, comprises the raw material of following weight part:

[0056]

[0057] The preparation method of described epoxy acrylate comprises the steps:

[0058] (R1), get 100 parts of epoxy resin, 33 parts of acrylic acid, 0.01 part of hydroquinone, 0.05 part of triethylamine and 10 parts of vinyl alkoxysilane oligomers by weight, for subsequent use;

[0059] (R2), after mixing acrylic acid, hydroquinone and triethylamine, a mixed solution is obtained;

[0060] (R3) Stir the epoxy resin and raise the temperature to 90°C, then continue to drop the mixed solution, and react at a temperature of 110°C for 2 hours to obtain a semi-finished product;

[0061] (R4), adding vinyl alkoxysilane oligomer to the semi-finished product, then stirring and reacting for 0.5h at 50°C under the catalysis of organotin, distilling under reduced pressure, washing, drying and filtering to obtain epoxy acrylic acid ester.

[0062] The epoxy resin is EP-16; the vinyl alko...

Embodiment 3

[0073] A kind of UV printing ink, comprises the raw material of following weight part:

[0074]

[0075]

[0076] The preparation method of described epoxy acrylate comprises the steps:

[0077] (R1), get 100 parts of epoxy resin, 36 parts of acrylic acid, 0.05 part of hydroquinone, 0.1 part of triethylamine and 30 parts of vinyl alkoxysilane oligomers by weight, for subsequent use;

[0078] (R2), after mixing acrylic acid, hydroquinone and triethylamine, a mixed solution is obtained;

[0079] (R3) Stir the epoxy resin and heat it up to 100°C, then continue to drop the mixed solution, and react at a temperature of 120°C for 4 hours to obtain a semi-finished product;

[0080] (R4), add vinyl alkoxysilane oligomer to the semi-finished product, then stir and react at 100°C for 3 hours under the catalysis of organotin, distill under reduced pressure, then wash, dry and filter to obtain epoxy acrylate .

[0081] The epoxy resin is EP-16; the vinyl alkoxy silane oligomer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com