Industrial production method of 1, 3-dioleic acid-2-palmitic acid triglyceride and product

A technology of palmitic acid triglyceride and a production method, applied in the field of oils and fats, can solve the problems of low OPO content, increased production costs, harmful substances, harsh conditions, etc., and achieves the effects of reducing workload, avoiding adverse effects, and reducing acyl transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

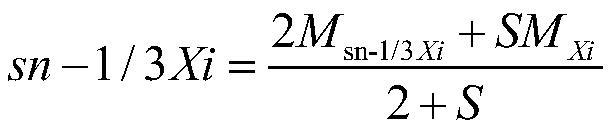

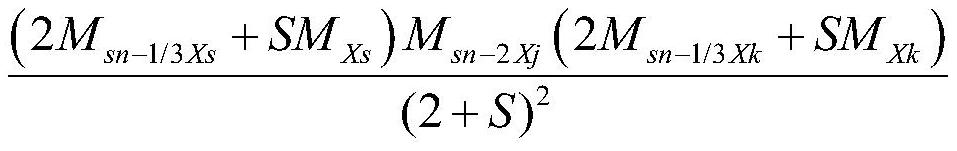

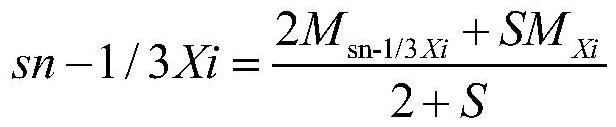

[0036] Establishment of enzymatic acid hydrolysis prediction model:

[0037] In the reaction system, the content of triglyceride is m, and the content of fatty acid is h. During the reaction, the lipase used is sn-1,3 position-specific lipase, and the fatty acid conforms to sn-1,3 position randomly distributed. In the whole reaction system, the types of fatty acids are defined as n types, different fatty acids are defined as Xi, and the reaction conditions are used to control the acyl transfer. The change of sn-2 fatty acid is small, so the change of sn-2 fatty acid can be ignored. In the system, the fatty acids involved in the reaction are mainly triglyceride sn-1,3 fatty acids and added free fatty acids. For a single fatty acid Xi, the molar percentage of Xi fatty acid on the sn-1,3 position of triglyceride can be expressed as Msn-1 / -3Xi, and the molar percentage of free fatty acid Xi can be expressed as MXi, therefore, when the system reaches the reaction equilibrium, Acc...

Embodiment 2

[0058] With palmitic acid content of 91.2%, sn-2 palmitic acid content of 84.4% palm stearin as starting material, high oleic sunflower oil fatty acid as acyl donor, sn-1, 3-position selective lipase As a catalyst, through the acid hydrolysis fatty acid equilibrium model, the fatty acid composition and distribution of the enzymatic hydrolysis products with different substrate ratios are calculated under reaction equilibrium.

[0059] Table 2. Fatty acid characteristics of palm stearin and high oleic sunflower oil

[0060] stearin High Oleic Sunflower Oil Fatty acid (mol%) total sn-2 sn-1,3 total C14:0 1.4 0.5 1.85 C16:0 91.2 84.4 94.6 3.8 C18:0 3.1 4.5 2.4 3.1 C18:1omega-9 3.6 8.8 1 84.8 C18:2ω-6 0.7 1.8 0.15 7.5 C18:3ω-3 0.4

[0061] Table 3. Theoretical equilibrium values of sn-1,3 fatty acids and triglycerides in one acid hydrolysis

[0062]

[0063] From the above results, it can...

Embodiment 3

[0088] Palm stearin with a palmitic acid content of 82.4% and a sn-2 palmitic acid content of 73.5% was selected as a starting material to produce 1,3-dioleic acid-2- The fatty acid composition and distribution of palmitic acid triglyceride products, palm stearin and high oleic peanut oil are shown below.

[0089] Table 10. Fatty acid characteristics of palm stearin and high oleic peanut oil (%)

[0090]

[0091] Table 11. Theoretical equilibrium values of sn-1,3 fatty acids and triglycerides in one acid hydrolysis

[0092]

[0093]

[0094] From the above results, it can be seen that with the increase of the substrate ratio, the content of sn-1,3 palmitic acid also decreases continuously, but the reduction range decreases. When the substrate ratio is greater than 10:1, the reduction of palmitic acid is less than 3%. Using the first enzymatic acid hydrolysis product as the substrate, and then using the same proportion of fatty acids for secondary acid hydrolysis, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com