Novel environment-friendly launching nitrate material and proportion thereof

An environmentally friendly and new technology, which is applied in the types of weapons, offensive equipment, pyrotechnics, etc., can solve the problems of poor firing effect and complex formula, and achieve the effect of lower price, simple materials, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

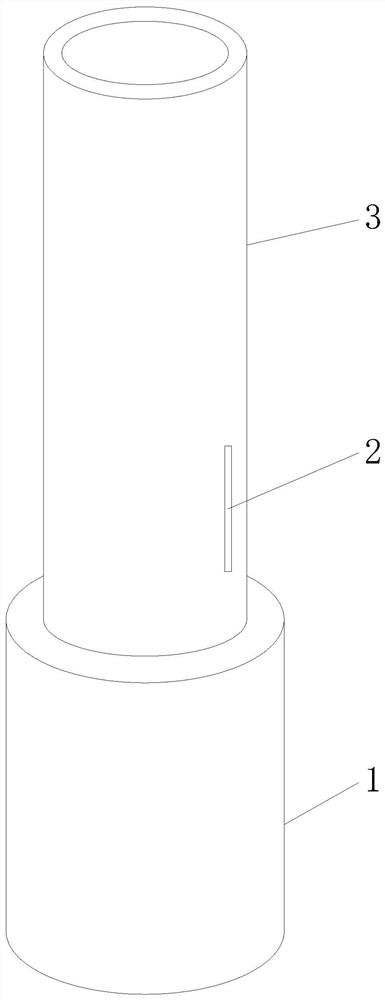

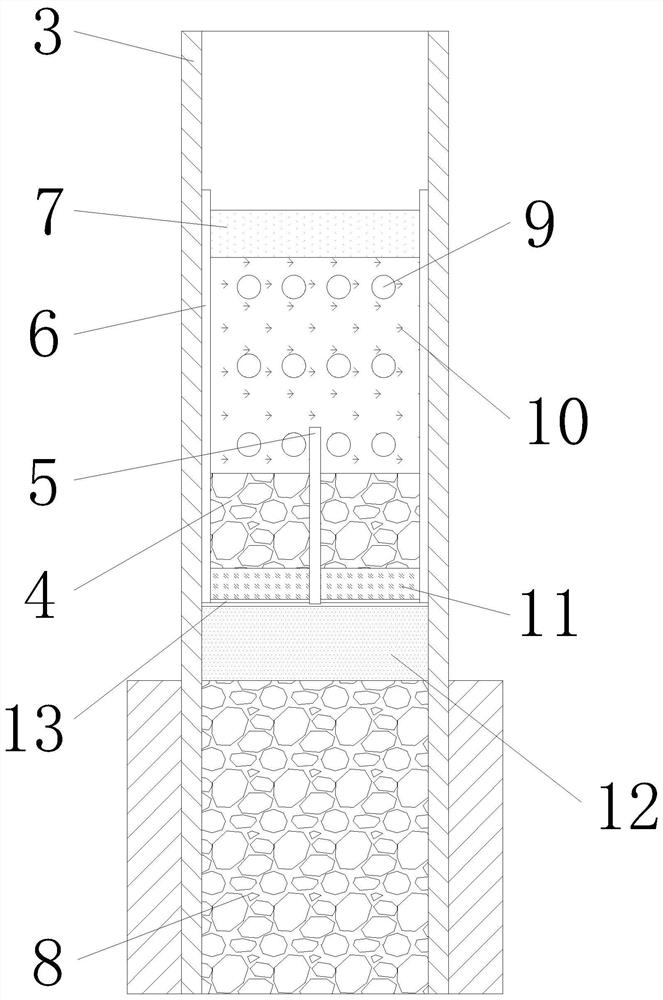

[0026] like Figure 1-2 As shown, embodiments of the present invention provide a new type of environmentally friendly emitting nitated material and ratio, including the following steps:

[0027] According to the formulation, we can weigh the weight of the weight: 20 parts of toner, 15 phenolic resins, 5-12 lacquer, 55-62 cophenate, 55-62 perchlorate, carbon powder: phenolic Resin: Painted sheet: Potassium phthalate: proportion of potassium perchlorate is 4: 3: 2: 3: 12;

[0028] Add toner, phenolic resin, lacquer, oxidyl hydroximetate, and potassium oxoic acid, and mixed with hydrocarbon, and stirred at a stirring time of 30 minutes, and stirred at a stirring time of 30 minutes, stirring the container and stirring rod For the wood material, the insulation treatment can be prepared to produce nitrate 12, and then the nitride 12 is reached into the short tube gun.

[0029] The short tube fly gun includes a base 1, the upper surface position of the base 1 penetrates the outer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com