Flexible miniature supercapacitor and manufacturing method thereof

A technology of supercapacitors and manufacturing methods, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problem that the process flow is not easy to integrate flexible and wearable substrates, affects interdigitated micro-flexible supercapacitors, and the environment has high environmental problems. requirements and other issues, to achieve the effect of improving electrochemical performance, good mechanical performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

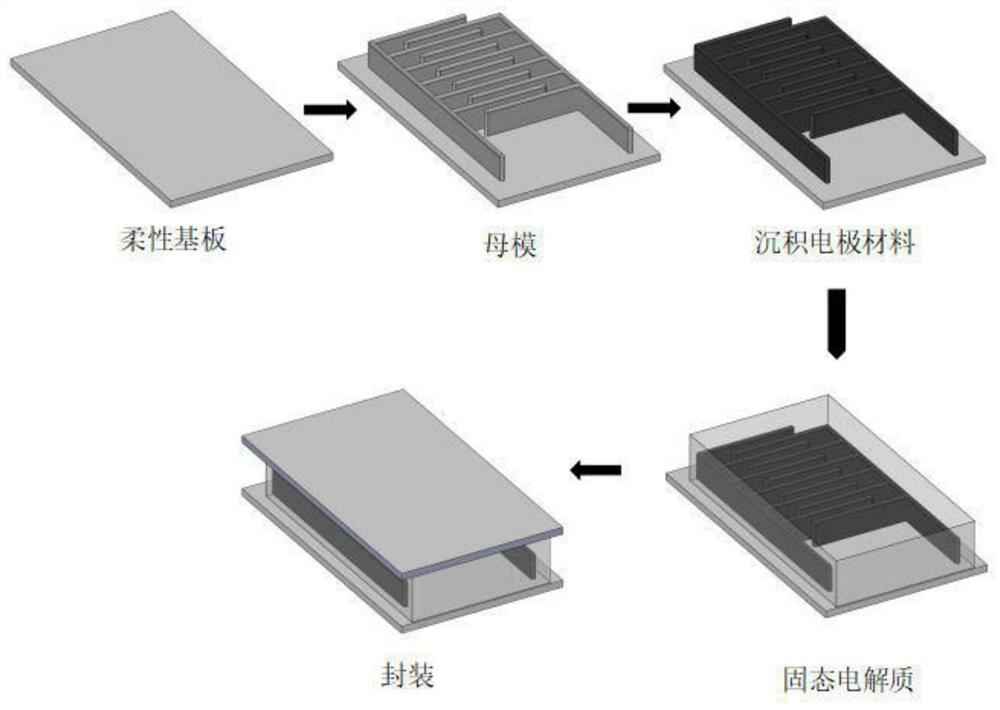

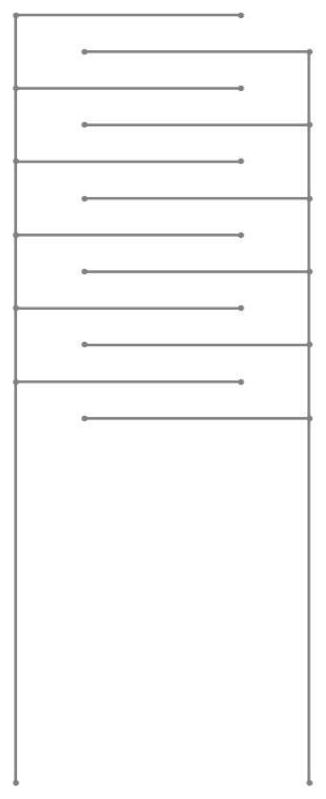

[0050] Using electric field-driven spray deposition micro-nano 3D printing technology and electrochemical polymerization process to manufacture micro-flexible supercapacitors, select PDMS as the micro-flexible substrate, select conductive silver paste 201s (a kind of flexible conductive silver paste) as the conductive substrate, and select PPy as the electrode material , the solid electrolyte is LiCl / PVA gel electrolyte, and the interdigital structure adopts linear interdigitation such as figure 2 shown. Its process is as figure 1 As shown, the specific preparation steps include:

[0051] (1) Fabrication of micro-flexible substrates

[0052] Ordinary glass was used as the substrate; the glass substrate was first cleaned, deionized water was ultrasonically treated for 10 min, and then dried with nitrogen. On the glass substrate, a layer of PDMS film was prepared by electric field-driven spray deposition micro-nano 3D printing technology, and an appropriate amount of Dow Cor...

Embodiment 2

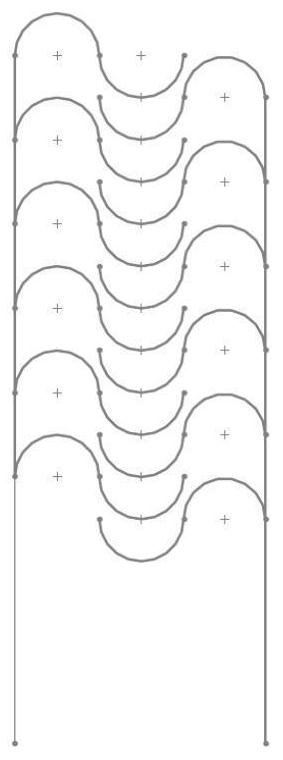

[0063] Micro-nano 3D printing technology driven by electric field-driven spray deposition and electrochemical polymerization process are used to fabricate micro-flexible supercapacitors. Ecoflex is selected as the micro-flexible substrate, TPU and Ag mixture are used as conductive materials, PANI is selected as electrode material, and solid electrolyte is H 2 SO 4 / PVA gel electrolyte, the finger structure adopts curved fingers. Concrete preparation steps include:

[0064] (1) Fabrication of micro-flexible substrates

[0065] Using silicon wafers as the substrate: firstly, the silicon wafer substrate is cleaned, deionized water is ultrasonically treated for 10 minutes, and then blown dry with nitrogen gas. On the glass substrate, a layer of Ecoflex film is prepared by using electric field-driven spray deposition micro-nano 3D printing technology. Choose Smooth-on, Ecofiex00-30 platinum-cured silica gel, A:B mass preparation ratio 1:1, its thickness is about 10 μm, and its ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com