Carbon nanotube-in-tube@manganous-manganic oxide nanoparticle composite material, and preparation method and application thereof

A technology for oxidizing manganese nanometers and carbon nanotubes, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of shedding, limited protection, limited load capacity, etc., to achieve increased load capacity, high mechanical strength, The effect of specific capacity and cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

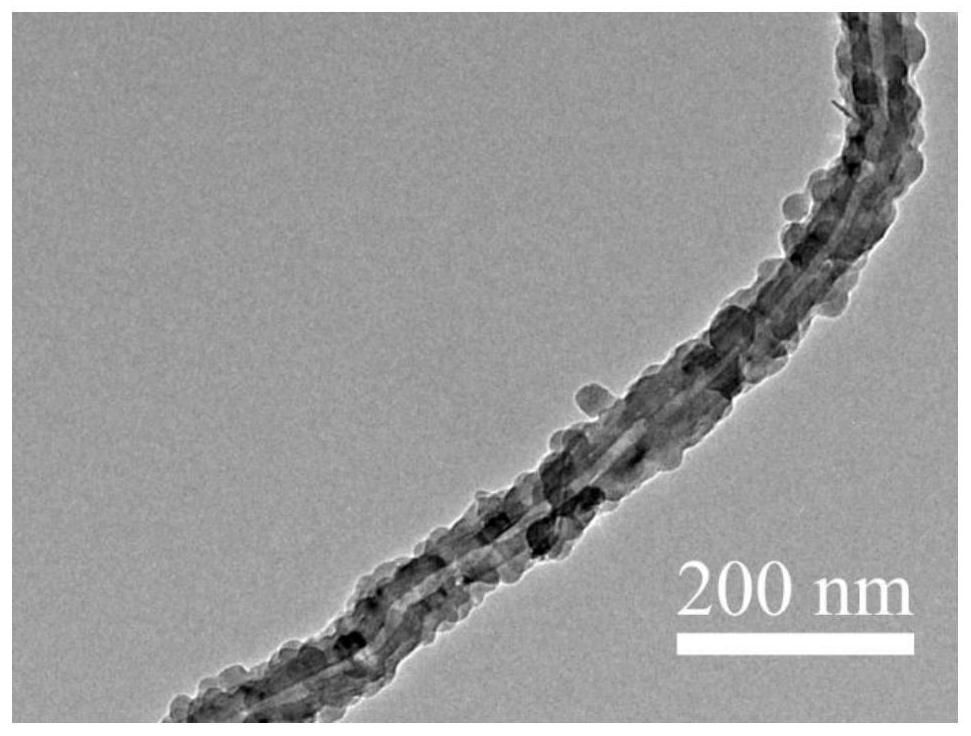

[0031] (1) 120mg Zn(NO 3 ) 2 ·6H 2 O was dissolved in 10ml methanol. 325 mg of 2-methylimidazole was dissolved in another 10 ml of methanol, and then 20 mg of acidified CNTs (30-50 nm in outer diameter, 7-10 nm in wall thickness) were further dispersed in this solution. Stir and mix the above two solutions, and further stir for 10min, pour the mixed solution into a 50mL Teflon autoclave, heat the autoclave to 90°C for 6h, cool to room temperature, centrifuge the product, and wash it with methanol for 3 times , and dried at 80°C to obtain ZIF-8@CNTs.

[0032] (2) Add 50mg ZIF-8@CNTs into 25ml ethanol. Then 25ml of aqueous solution in which 50mg of tannic acid was dissolved was added to the ZIF-8@CNTs solution, the product was separated after stirring for 5min, washed repeatedly, dried at 80°C, and the product was placed in a tube furnace and heated to Insulate at 600°C for 2h, heating rate 2°Cmin -1 . Then, the carbonized product was immersed in 0.2M HCl solution for 2 h...

Embodiment 2

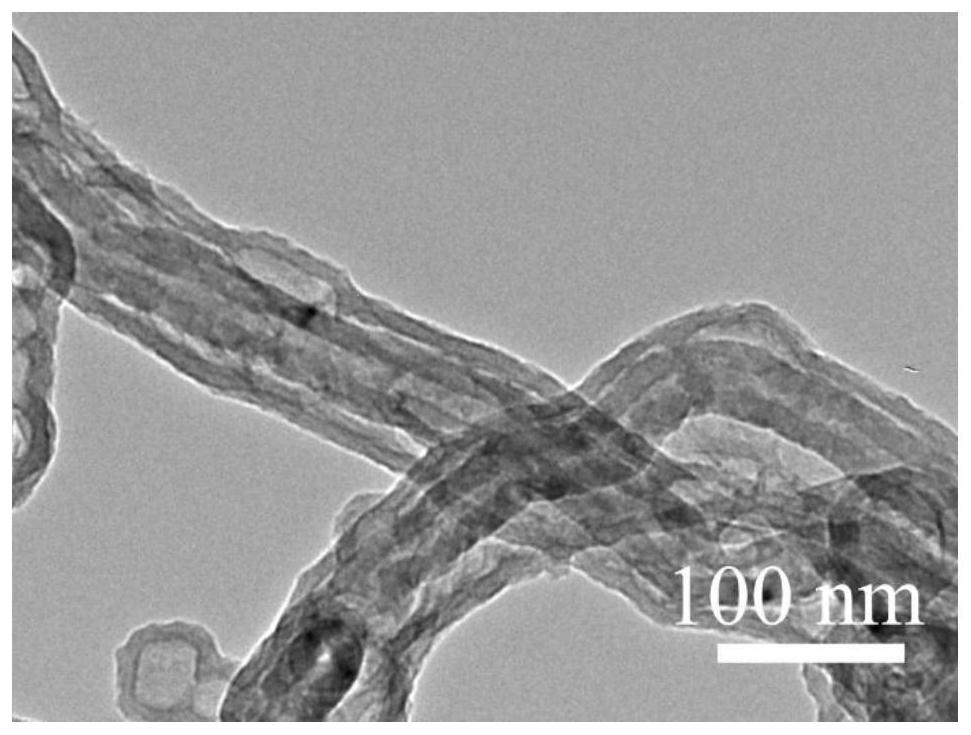

[0040] (1) 120mg Zn(NO 3 ) 2 ·6H 2 O was dissolved in 10ml methanol. 325 mg of 2-methylimidazole was dissolved in another 10 ml of methanol, and then 20 mg of acidified CNTs (30-50 nm in outer diameter, 7-10 nm in wall thickness) were further dispersed in this solution. Stir and mix the above two solutions, and further stir for 10min, pour the mixed solution into a 50mL Teflon autoclave, heat the autoclave to 90°C for 6h, cool to room temperature, centrifuge the product, and wash it with methanol for 3 times , and dried at 80°C to obtain ZIF-8@CNTs.

[0041] (2) Add 50mg ZIF-8@CNTs into 25ml ethanol. Then 25ml of aqueous solution in which 50mg of tannic acid was dissolved was added to the ZIF-8@CNTs solution, the product was separated after stirring for 5min, washed repeatedly, dried at 80°C, and the product was placed in a tube furnace and heated to Insulate at 600°C for 2h, heating rate 2°Cmin -1 . Then, the carbonized product was immersed in 0.2M HCl solution for 2 h...

Embodiment 3

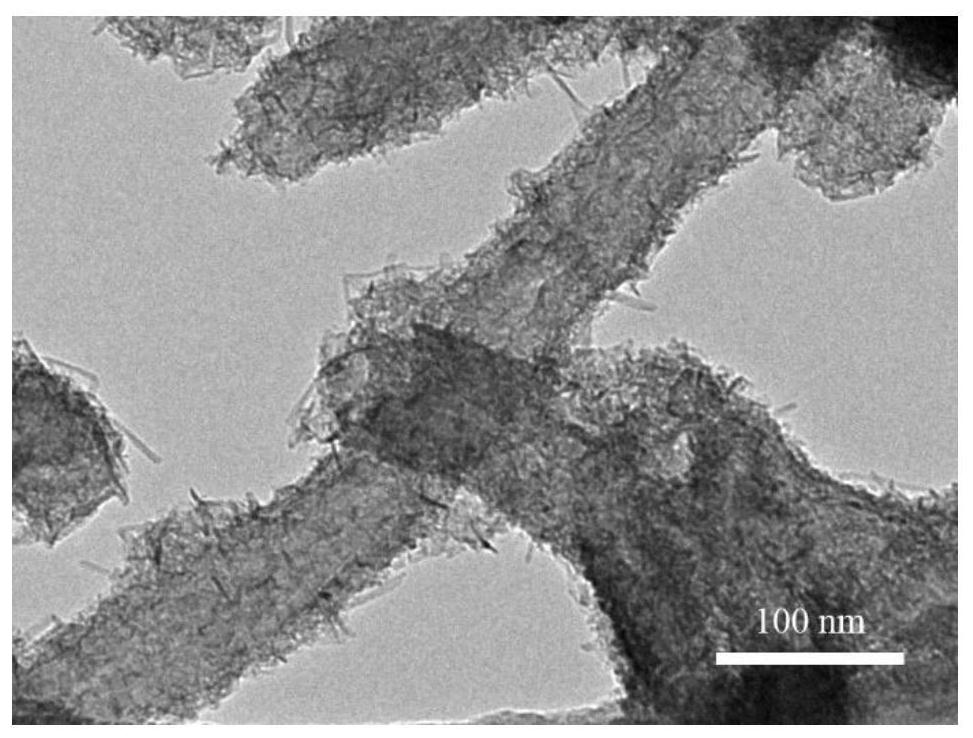

[0047] (1) 120mg Zn(NO 3 ) 2 ·6H 2O was dissolved in 10ml methanol. 325 mg of 2-methylimidazole was dissolved in another 10 ml of methanol, and then 20 mg of acidified CNTs (30-50 nm in outer diameter, 7-10 nm in wall thickness) were further dispersed in this solution. Stir and mix the above two solutions, and further stir for 10min, pour the mixed solution into a 50mL Teflon autoclave, heat the autoclave to 90°C for 6h, cool to room temperature, centrifuge the product, and wash it with methanol for 3 times , and dried at 80°C to obtain ZIF-8@CNTs.

[0048] (2) Add 50mg ZIF-8@CNTs into 25ml ethanol. Then 25ml of aqueous solution in which 50mg of tannic acid was dissolved was added to the ZIF-8@CNTs solution, the product was separated after stirring for 5min, washed repeatedly, dried at 80°C, and the product was placed in a tube furnace and heated to Insulate at 600°C for 2h, heating rate 2°Cmin -1 . Then, the carbonized product was immersed in 0.2M HCl solution for 2 h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com