A kind of preparation method of semi-solid polyionic liquid electrolyte for lithium battery

A technology of polyionic liquids and electrolytes, which is applied in the field of electrolytes, can solve problems such as easy leakage of electrolytes, achieve the effects of improving safety, reducing packaging requirements, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of semi-solid polyionic liquid electrolyte for lithium battery. Specific steps are as follows:

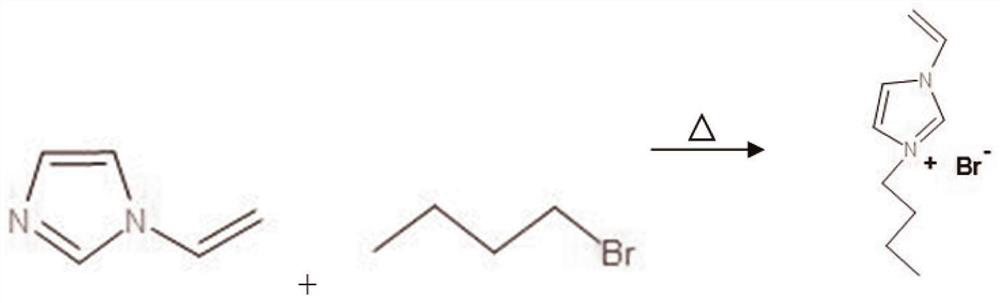

[0060] 1. Ionic liquid monomer prepared by chemical synthesis method: vinylimidazole reacts with n-butane bromide in an oil bath at 50°C to generate 1-butyl-3-vinylimidazolium bromide (intermediate 1), which is at room temperature It is a viscous solid, and its reaction structure is as follows figure 1 shown;

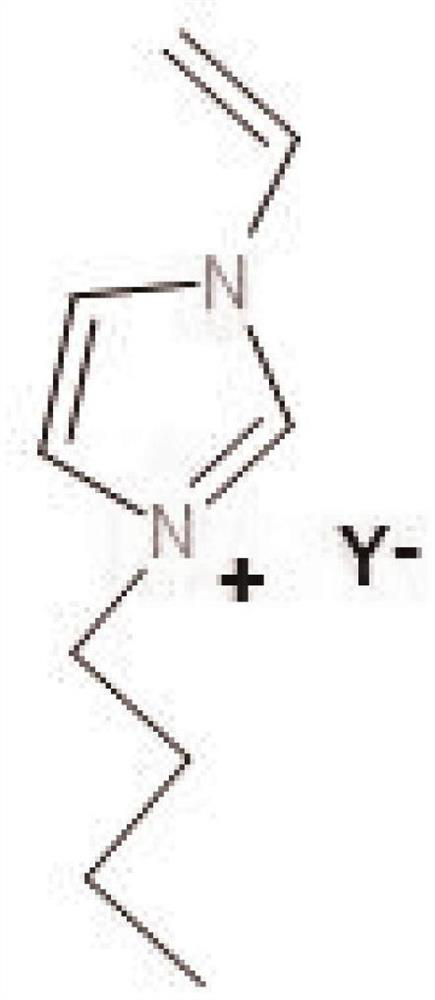

[0061] 2. After reacting equimolar intermediate 1 with sodium hexafluorophosphate (NaPF6) in an aqueous solution for 8 hours, the lower layer was taken out, purified, and the yield was 90% to obtain a liquid 1-butyl-3- Vinylimidazole hexafluorophosphoric acid (ionic liquid monomer 1), its structural formula is as figure 2 shown (Y - For: PF6 - );

[0062] 3. Mix the ionic liquid monomer 1 with lithium hexafluorophosphate to form an electrolyte (electrolyte monomer 1) with a concentration of 1M lithium hexafluorophosphate;

[0063] 4. Add 1...

Embodiment 2

[0067] A preparation method of semi-solid polyionic liquid electrolyte for lithium battery. Specific steps are as follows:

[0068] 1. Ionic liquid monomer prepared by chemical synthesis method: vinylimidazole reacts with n-butane bromide in an oil bath at 50°C to generate 1-butyl-3-vinylimidazolium bromide (intermediate 1), which is at room temperature It is a viscous solid, and its reaction structure is as follows figure 1 shown;

[0069] 2. After an equimolar amount of intermediate 1 was reacted with lithium bisfluorosulfonimide (LiFSI) in an aqueous solution for 8 hours, the lower layer was taken out, purified, and the yield was 85% to obtain a liquid 1-butyl at room temperature -3-vinylimidazole bisfluorosulfonimide (ionic liquid monomer 2), its structural formula is as follows figure 2 Shown (Y- is: FSI - );

[0070] 3. Mix the ionic liquid monomer 2 with lithium bisfluorosulfonimide to form an electrolyte (electrolyte monomer 2) with a concentration of 1M lithium ...

Embodiment 3

[0075] A preparation method of semi-solid polyionic liquid electrolyte for lithium battery. Specific steps are as follows:

[0076] 1. Ionic liquid monomer prepared by chemical synthesis method: vinylimidazole reacts with n-butane bromide in an oil bath at 50°C to generate 1-butyl-3-vinylimidazolium bromide (intermediate 1), which is at room temperature It is a viscous solid, and its reaction structure is as follows figure 1 shown;

[0077] 2. After an equimolar amount of intermediate 1 was reacted with lithium bistrifluoromethanesulfonimide (LiTFSI) in an aqueous solution for 4 hours, the subnatant was taken out, purified, and the yield was 90% to obtain 1 that was a liquid at room temperature. -Butyl-3-vinylimidazole bis-trifluoromethylsulfonimide ionic liquid (ionic liquid monomer 3), its structural formula is as follows figure 2 Shown (Y- is: TFSI - );

[0078] 3. Mix the ionic liquid monomer 3 with lithium bis-trifluoromethylsulfonimide to form an electrolyte (elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com