Low-temperature-resistant polymer cement waterproof coating and preparation method thereof

A waterproof coating and polymer technology, applied in the direction of coating, etc., can solve the problems of poor stability in use and poor low temperature resistance of cured coating films, so as to improve the stability of low temperature use, good low temperature storage stability, and reduce low temperature The effect of the likelihood of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

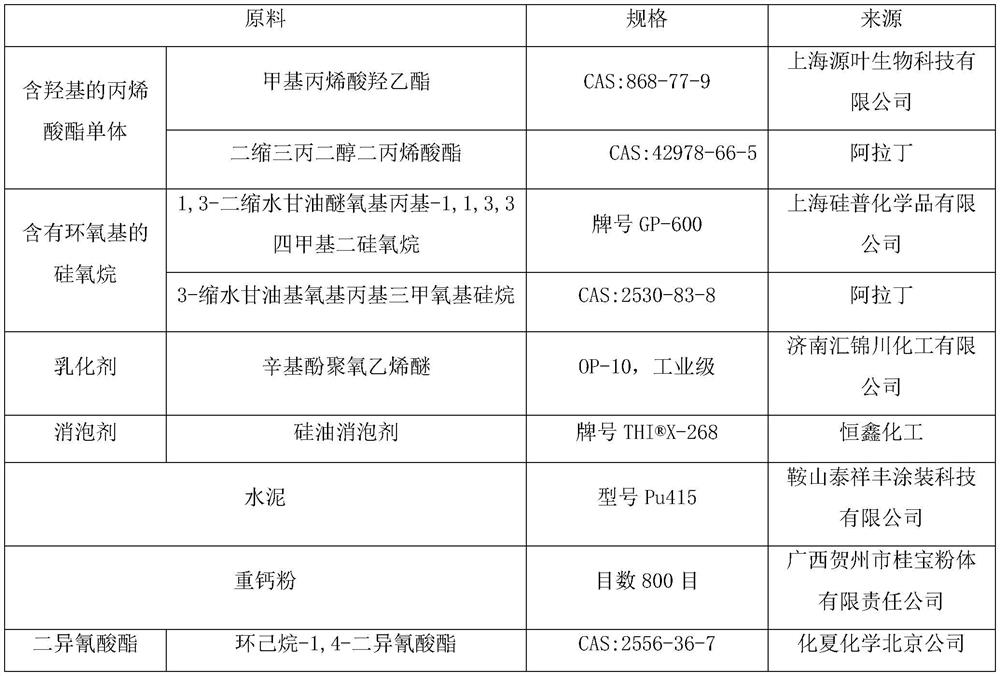

preparation example

[0044] A modified polyacrylate emulsion is prepared according to the following preparation method:

[0045]S1. Weigh 0.2kg of emulsifier OP-10 and dissolve it in 9.8kg of deionized water, stir and mix at a speed of 600rpm, and prepare an emulsion;

[0046] Weigh 3.3kg hydroxyethyl methacrylate, 3.3kg methacrylate, 1.1kg methacrylic acid and 1.1kg3-glycidyloxypropyltrimethoxysilane;

[0047] Take 0.3kg of hydroxyethyl methacrylate, 0.3kg of methacrylate, 0.1kg of methacrylic acid and 0.1kg of 3-glycidyloxypropyltrimethoxysilane into the emulsion, stir and mix at a speed of 600rpm Carry out emulsification to obtain a pre-emulsion; add 0.1kg of potassium persulfate solution with a concentration of 0.01wt% to the pre-emulsion, stir at a speed of 600rpm and heat up to 75°C, then keep warm for 0.3h to obtain a seed emulsion;

[0048] S2. Raise the temperature of the seed emulsion to 80°C, then put the remaining hydroxyethyl methacrylate, methacrylate, methacrylic acid and 3-glycidy...

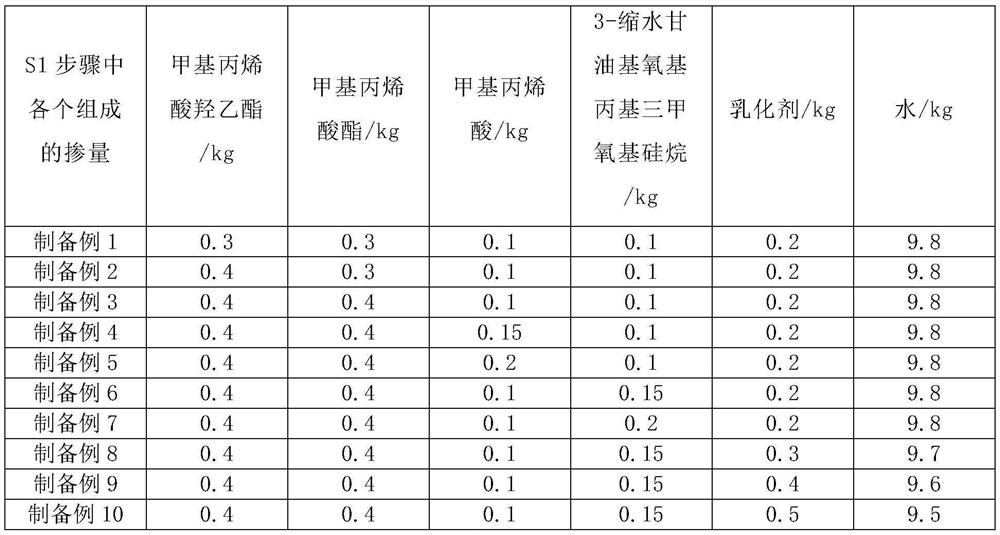

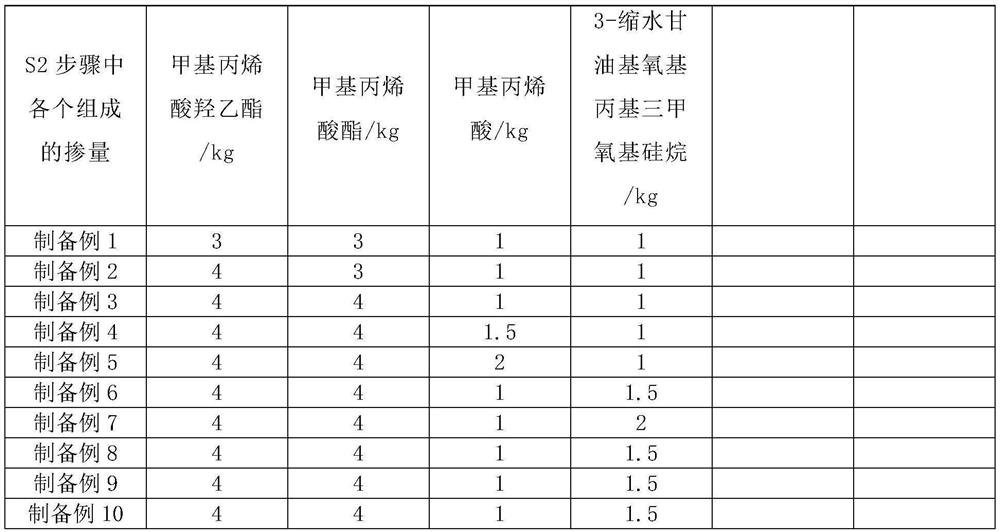

preparation example 2-10

[0050] A modified polyacrylate emulsion, the difference from Preparation Example 1 is that hydroxyethyl methacrylate, methacrylate, methacrylic acid, 3-glycidyloxypropyltrimethoxysilane and emulsifier The dosing amount is different, and the specific dosing amount is shown in Table 2 below.

[0051] Table 2. The dosage of each component of the modified polyacrylate emulsion in each step

[0052]

[0053]

preparation example 11

[0055] A modified polyacrylate emulsion, the difference from Preparation Example 9 is that 1,3-diglycidyl etheroxypropyl-1,1,3,3 tetramethyldisiloxane is used to replace 3 - glycidyloxypropyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com