Stainless steel ultrasonic sheet chemiluminescence solution detection device and using method thereof

A technology of chemiluminescence and detection devices, which is applied in the directions of chemiluminescence/bioluminescence, measuring devices, and analysis by making materials undergo chemical reactions, which can solve the problems of restricting wide application, expensive devices, and large volume, and achieve convenient use, Create cheap, small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

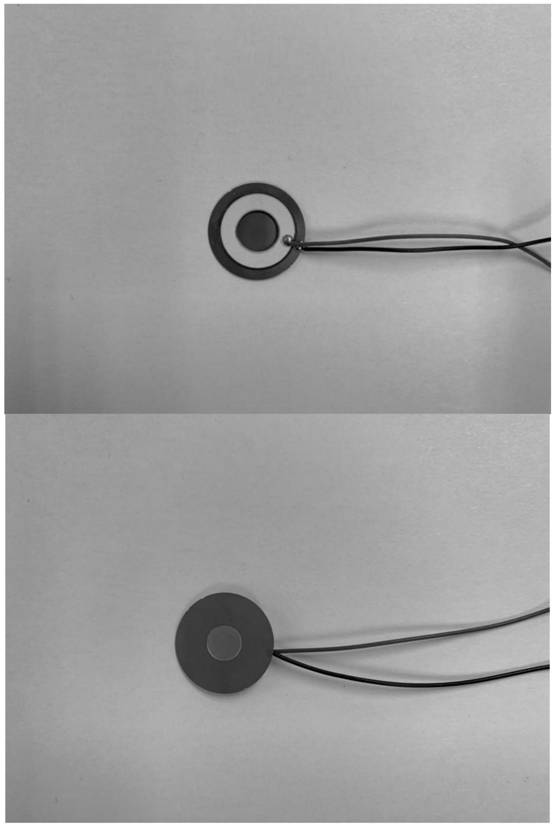

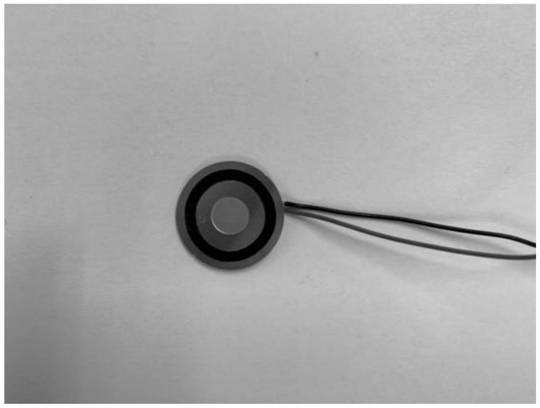

[0076] Preparation of stainless steel ultrasonic sheet chemiluminescence solution detection device

[0077] On the basis of the microporous stainless steel atomizing sheet of the household USB humidifier, the porous stainless steel sheet on the stainless steel microporous atomizing sheet is replaced with a non-porous stainless steel sheet, and a ring-shaped plastic insulating sheet is attached to the non-piezoelectric ceramic ring surface to form Grooves with a diameter of 10mm.

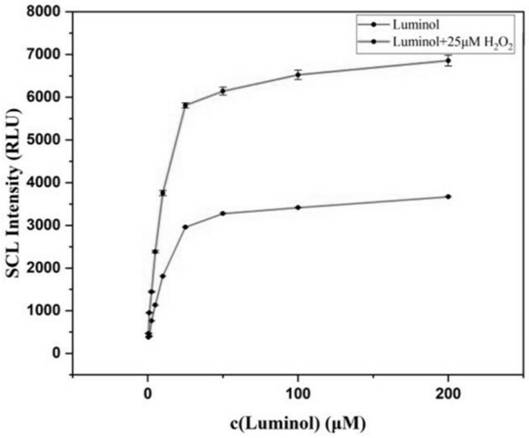

[0078] Then add the chemiluminescent solution (luminol solution with a certain gradient in the range of 0.5-200 μM, and the above-mentioned luminol solution and 25 μM hydrogen peroxide solution) into the groove respectively, the addition amount is generally 30-50 μL and then pass Ultrasonic vibration of the stainless steel ultrasonic plate causes ultrasonic chemiluminescence.

[0079] The ultrasonic chemiluminescence process of the chemiluminescence solution detected by the chemiluminescence solutio...

Embodiment 2

[0083] The relationship between the pH of CBS buffer and the intensity of ultrasonic chemiluminescence (SCLIntensity).

[0084] Example of pH Condition Optimization

[0085] Configure different pH detection solutions (the pH gradient is: 9.4, 10, 10.5, 11, 11.5, 12, 12.5, 13), add the mixed solution in the reaction groove on the reverse side of the present invention, and use ultrasonic action to cause ultrasonic chemiluminescence.

[0086] see Figure 4 , Figure 4 It is the relationship curve between the pH of the CBS buffer solution and the intensity of ultrasonic chemiluminescence (SCLIntensity) in Example 2 of the present invention.

[0087] When the pH=12 of CBS buffer [other experimental conditions: c(Luminol)=100μM, c(H 2 o 2 )=25 μ M], the luminous intensity reaches the maximum value, and the pH intensity continues to increase and decreases instead, so the pH value of the CBS buffer solution can be selected as 12 when detecting hydrogen peroxide and glucose concent...

Embodiment 3

[0089] Relationship between hydrogen peroxide concentration and SCL intensity

[0090] When the pH of the CBS buffer was 12 [other experimental conditions: c (Luminol) = 100 μ M], the luminous intensity reached the maximum value, and continued to increase the pH intensity but decreased. Choose pH 12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com