Method for processing negative pole piece, sodium metal negative pole piece and electrochemical device

A technology of negative electrode sheet and processing method, which is applied in the field of secondary batteries, and can solve the problems of unrealistic commercial application, easy generation of sodium dendrites, low melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

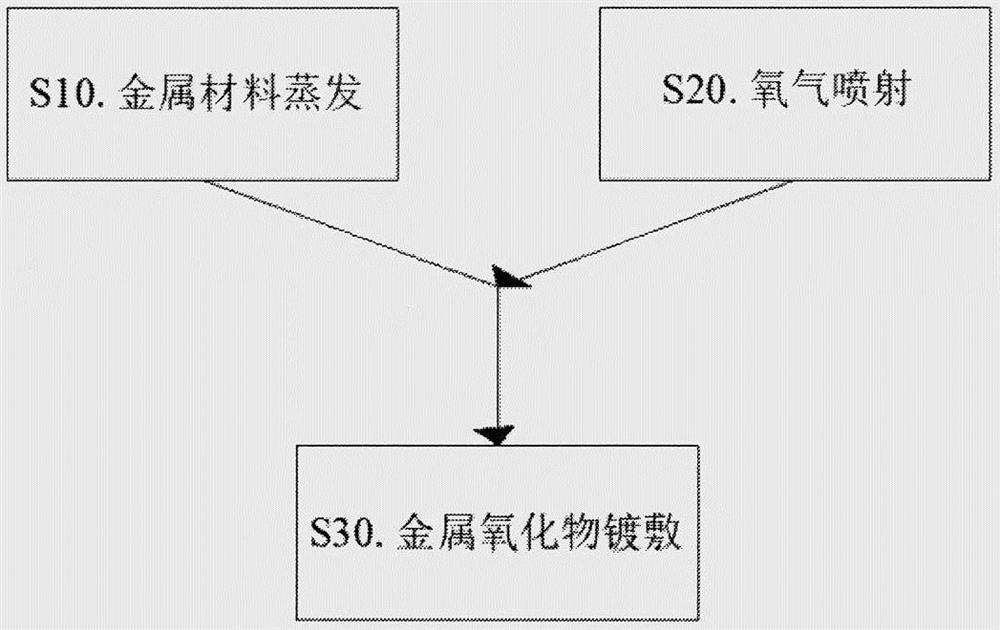

Method used

Image

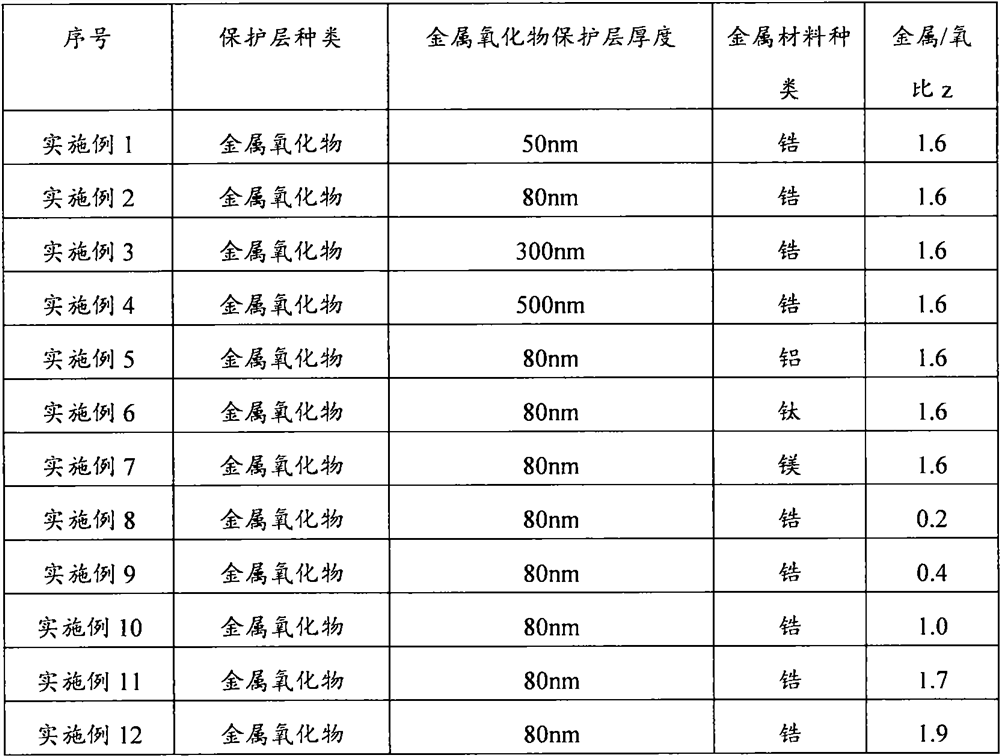

Examples

Embodiment 1

[0084] (1) Preparation of negative electrode sheet:

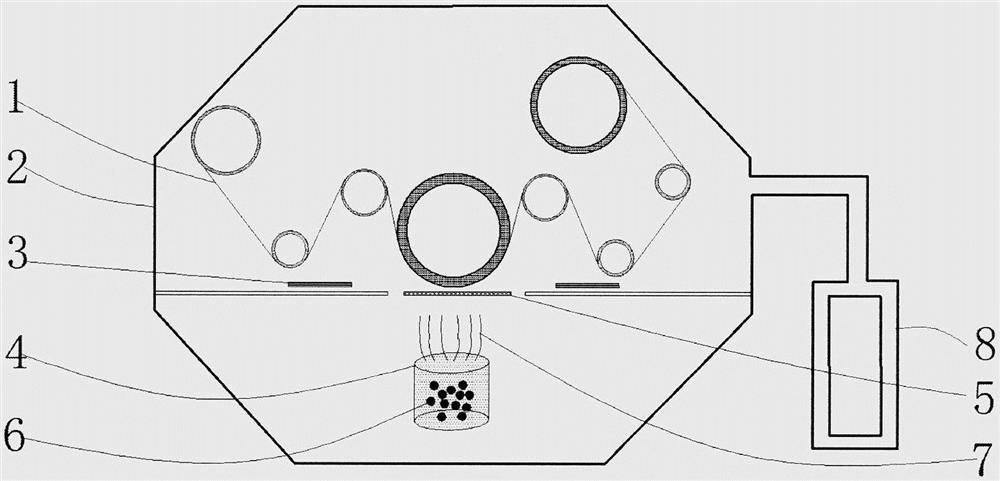

[0085] S1. Place the negative pole piece 1 in a vacuum chamber 2 through the transmission mechanism, and at the same time place the metal material 6, that is, the zirconium material in a metal vapor generator 4, the density of the zirconium material is 6.49g / cm 3 , with a relative atomic mass of 91. The metal vapor generator 4 is set in the vacuum chamber 2. When the vacuum degree in the vacuum chamber 2 reaches the threshold requirement, the zirconium material continues to melt and evaporate in the metal vapor generator 4 to form a metal vapor 7. The ejection flow rate of the metal vapor 7 The negative electrode sheet 1 was immersed in the metal vapor 7 at 500 ml / min. Among them, the vacuum degree can be realized by the vacuum unit 8, and the vacuum degree is ≤8×10 -2 Pa, the threshold requirement of the vacuum degree can be realized by setting the parameters of the vacuum unit 8 . A porous barrier layer 5 is arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com