Vibrating diaphragm and loudspeaker

A silicone rubber and polyether technology, applied in the direction of flat diaphragm, polymer material diaphragm, non-planar diaphragm/paper cone, etc., can solve the problems of unstable product, sticky material, low internal resistance, etc., and achieve less distortion , Good oleic acid resistance, great damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

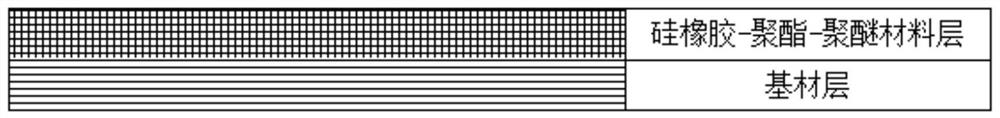

[0088] The damper film provided in this example is as figure 1 As shown, the diaphragm includes a layer of silicone rubber-polyester-polyether material layer and a layer of substrate layers, and two layers are connected between the two layers.

[0089] The silicone rubber-polyester-polyether material provided in this example includes the following components: silicone rubber 30g, polyester elastomer 60g, polyether elastomer 30g and coupling agent (triethoxyethylsilane) 0.1g.

[0090] The method of preparing the silicone rubber-polyester-polyether material provided in this example includes the step of: obtaining a polyester polyether material after copolymerization of a polyester elastomer and a polyether elastomer; polyester polyether The material is carried out in a vulcizing machine to obtain a mixture of silicone rubber; obtaining a mixture; granulating the mixture, in the process of granulation, adding a coupling agent to the mixture, then the film is obtained. Silicone rubber...

Embodiment 2

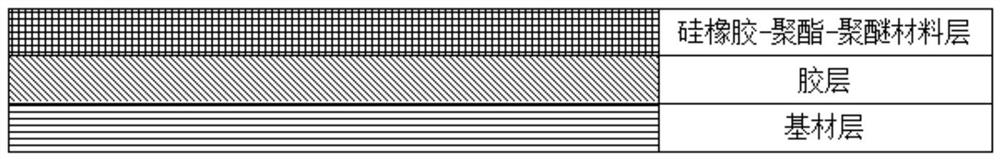

[0093] The damper film provided in this example is as figure 2 As shown, the diaphragm includes a layer of silicone rubber-polyester-polyether material layer, a layer of substrate layer and a layer of rubber, wherein the silicone rubber-polyester-polyether material layer and the substrate layer Connect by gel.

[0094] The silicone rubber-polyester-polyether material provided in this example includes the following components: silicone rubber 60g, polyester elastomer 30g, polyether elastomer 30g, silica microspheres, 5G, and coupling agents ( Trichloropropylsilane) 5g.

[0095] The method of preparing the silicone rubber-polyester-polyether material provided in this example includes the step of: obtaining a polyester polyether material after copolymerization of a polyester elastomer and a polyether elastomer; polyester polyether The material is carried out in a vulcanization machine to obtain a mixture of silicone rubber, obtaining a mixture; the mixture is granulated, and the sili...

Embodiment 3

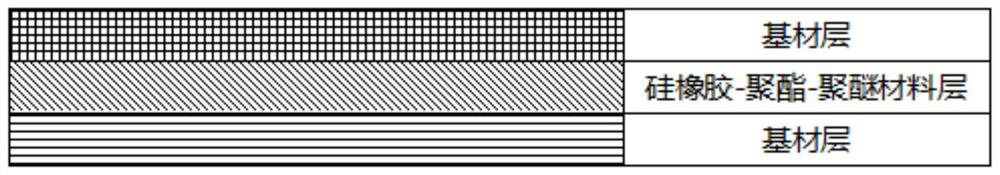

[0099] The damper film provided in this example is as image 3 As shown, the diaphragm includes a layer of silicone rubber-polyester-polyether material layer and two layers of substrate layers, wherein the silicone rubber-polyester-polyether material layer is an intermediate layer, and each layer is passed through a hot sticker. Connect.

[0100] The silicone rubber-polyester material provided in this example includes the following components: silicone rubber 40g, polyester elastomer 60g, polyether elastomer 60g, silica microspheres 3g, glass fiber 5g, Coupling agent (trihalikyl titanate isopropyl acid) 3 g and mica 20g.

[0101] The method of preparing the silicone rubber-polyester-polyether material provided in this example includes the step of: obtaining a polyester polyether material after copolymerization of a polyester elastomer and a polyether elastomer; polyester polyether The material is carried out in the vulcanization machine to obtain a vulcanization machine to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com