Method for breeding hermetia illucens larvae through three-phase separated solid-phase material in kitchen project

A three-phase separation, black soldier fly technology, applied in animal feed, animal husbandry, etc., can solve the problems of endangering environmental safety, poor economical incineration process, etc., and achieve the effect of thorough resource utilization, easy operation and great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

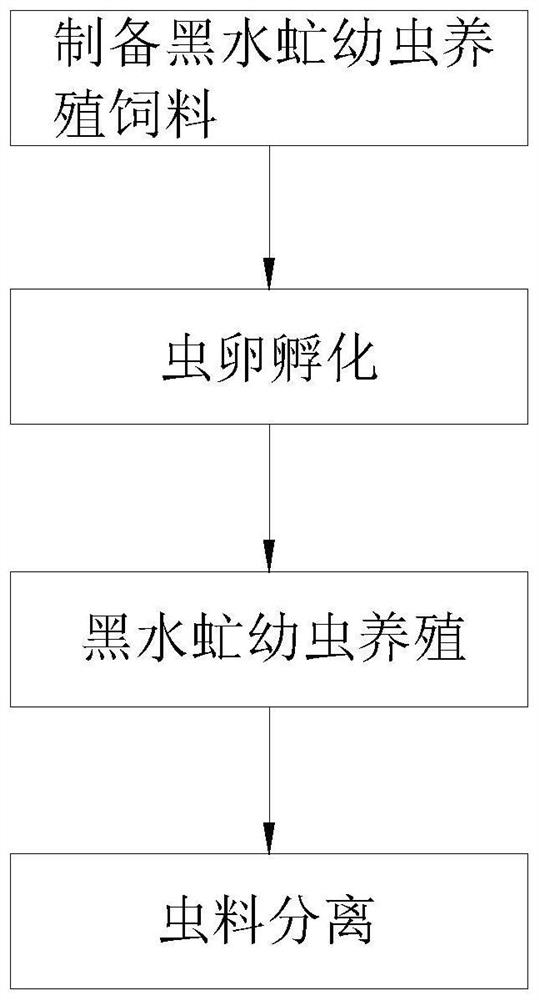

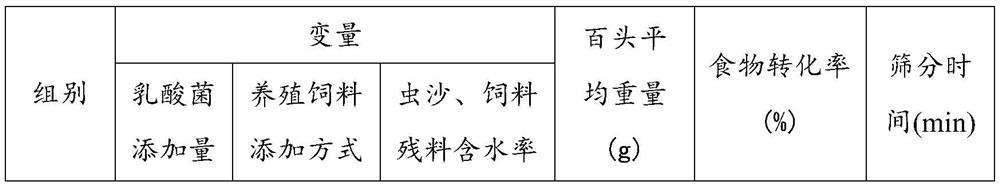

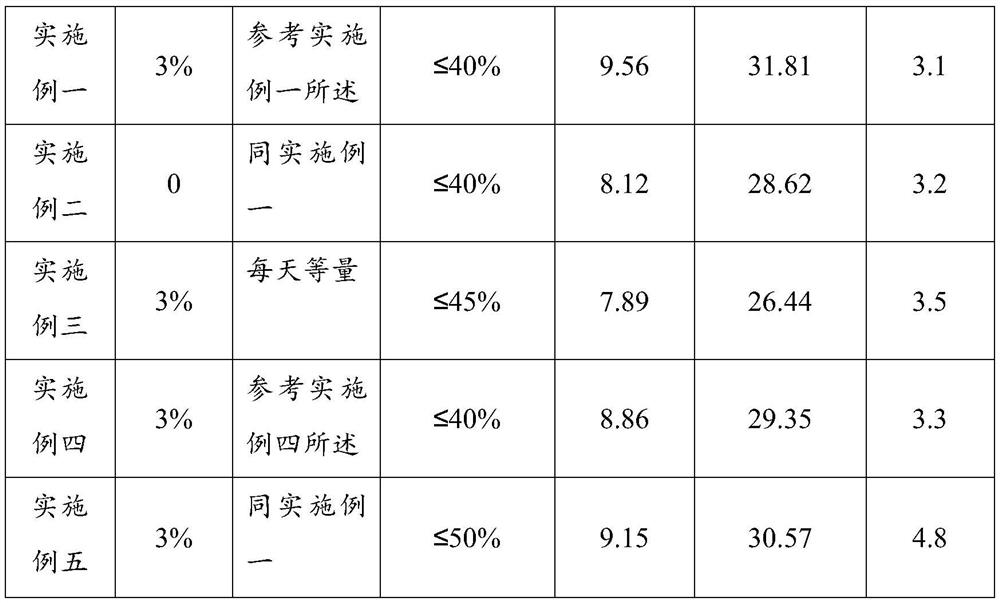

[0025] Such as figure 1 Shown, a kind of kitchen project three-phase separation solid-phase material cultures the method for black soldier fly larva, comprises the following steps:

[0026] S1a: Feed preparation for breeding black soldier fly larvae: three-phase centrifuged solid phase material is used as base material, supplementary material (rice bran, moisture content 13%) is added at 10%, lactic acid bacteria cultivated by wormwood endophyte is added at 3% and mixed Compound, moisture content 75%, airtight fermentation at room temperature of 25°C for 3 days;

[0027] The three-phase centrifuged solid phase material is subjected to high-temperature sterilization, impurity removal, dehydration, and oil removal. The specific process is to heat the material to 80°C after removing impurities through 2.5mm, cook for more than 4 hours, and dehydrate through a three-phase centrifuge. , degreasing;

[0028] The compounding process of three-phase centrifugal solid phase materials,...

Embodiment 2

[0035] A method for cultivating black soldier fly larvae with three-phase separation solid-phase materials for a kitchen project, comprising the following steps:

[0036] S1b: Feed preparation for breeding black soldier fly larvae: three-phase centrifuged solid-phase material is used as base material, supplementary material (rice bran, moisture content 13%) is added at 10%, and lactic acid bacteria cultivated by wormwood endophyte is added at 0%. Compound, moisture content 75%;

[0037]The three-phase centrifuged solid-phase material is subjected to high-temperature sterilization, impurity removal, dehydration, and oil removal. The specific process is to heat the material to 80°C after passing 2.5mm of impurity removal, cook for more than 4 hours, and dehydrate and remove oil.

[0038] S2b: Incubation of eggs: Weigh 1 kg of brooding feed and put it in the hatching box, put 20 g of eggs on the screen above the brooding feed, keep the hatching conditions at temperature 28-32°C, ...

Embodiment 3

[0042] A method for cultivating black soldier fly larvae with three-phase separation solid-phase materials for a kitchen project, comprising the following steps:

[0043] S1c: Feed preparation for breeding black soldier fly larvae: three-phase centrifuged solid phase material as base material, supplementary material (rice bran, moisture content 13%) is added at 10%, and lactic acid bacteria cultivated by endophytic wormwood is added at 3% mixed Compound, moisture content 75%, airtight fermentation at room temperature of 25°C for 3 days;

[0044] The three-phase centrifuged solid-phase material is subjected to high-temperature sterilization, impurity removal, dehydration, and oil removal. The specific process is to heat the material to 80°C after passing 2.5mm of impurity removal, cook for more than 4 hours, and dehydrate and remove oil.

[0045] S2c: Incubation of eggs: Weigh 1 kg of brooding feed and put it in the hatching box, put 20 g of eggs on the sieve above the brooding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com