An oil-resistant and salt-resistant foam flooding system with strong regenerative foam stability

A technology of foam stability and foam flooding, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as no special emphasis on foam stability, no attention to foam stability, unfavorable stability of oily foam, etc., to achieve Good oil resistance and salt resistance, improve the effect, improve the effect of fluidity control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) system preparation: take foaming agent 0.2g (wherein dodecyl glucoside 0.15g, lauryl amidopropyl betaine 0.05g), regeneration enhancer 0.06g (wherein cocamidopropyl amine oxide 0.05g, Bisperfluorooctyl sulfobetaine 0.01g), add 99.74g under low speed stirring, the salinity is 22×10 4 mg / L of simulated formation water (ie 22×10 4 mg / L NaCl aqueous solution), a foam system is obtained after it is completely dissolved.

[0021] (2) Test of foam oil resistance and salt resistance:

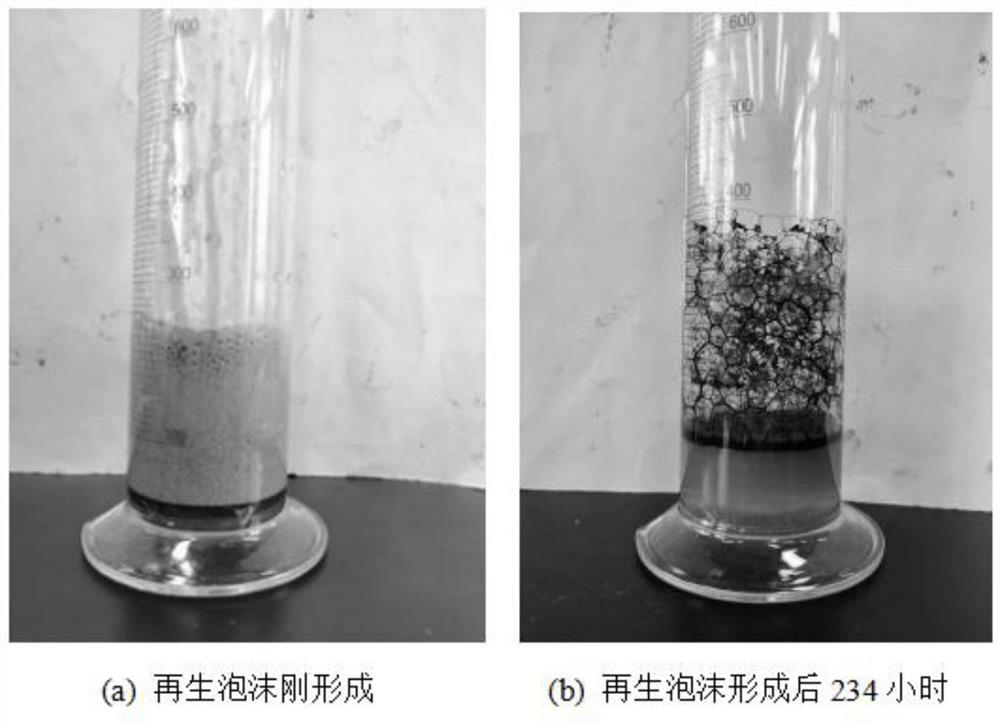

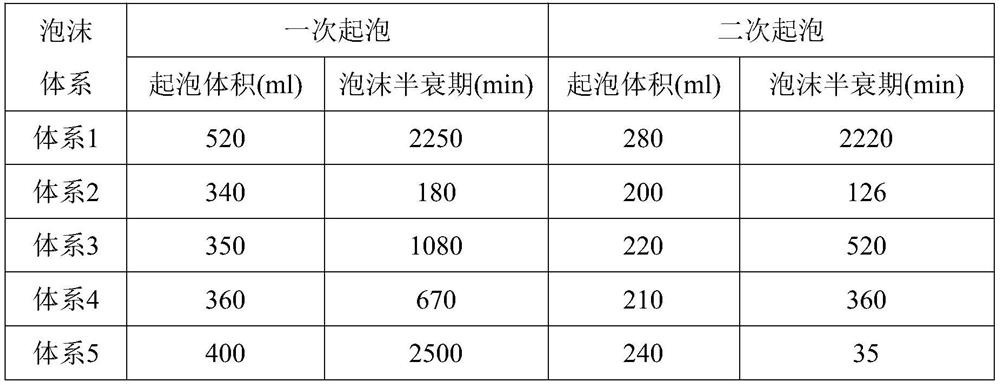

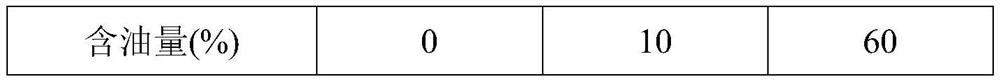

[0022] ①Influence of oil content: Pour 100ml of foam system and crude oil (viscosity of 643mPa·s) into a warning blender together with a certain proportion of its volume, stir for 1min at a shear rate of 6000 rpm, and measure the foam volume The results are shown in Table 1 (oil content=volume of crude oil / volume of foam system). The oil content increases and the foam stability increases.

[0023] Table 1 Effect of oil content on foam properties

[0024] Oil content (%) 0 10 ...

Embodiment 2

[0039] (1) system preparation: take foaming agent 0.3g (wherein decyl maltoside 0.2g, cocamidopropyl isosulbetaine 0.1g), proliferation enhancer 0.14g (wherein cocamidopropyl betaine 0.1g) , double fluorine-containing nonylcarboxylate betaine 0.04g), add 99.56g under low-speed stirring conditions, the salinity is 10 × 10 4 mg / L of simulated formation water (ie 10×10 4 mg / L NaCl aqueous solution), a foam system was obtained after it was completely dissolved.

[0040] (2) Test of foam oil resistance and salt resistance:

[0041] ①Influence of oil content: Pour 100ml of foam system and crude oil (viscosity of 643mPa·s) into a warning blender together with a certain proportion of its volume, stir for 1min at a shear rate of 6000 rpm, and measure the foam volume The results are shown in Table 4 (oil content=volume of crude oil / volume of foam system). The oil content increases and the foam stability increases.

[0042] Table 4 Effect of oil content on foam properties

[0043] ...

Embodiment 3

[0052] (1) system preparation: take foaming agent 0.24g (wherein decyl maltoside 0.2g, cocamidopropyl isosulbetaine 0.04g), proliferation enhancer 0.11g (wherein cocamidopropyl betaine 0.1g) , double fluorine-containing nonyl carboxylic acid betaine 0.01g), add 99.65g under low-speed stirring conditions, the salinity is 22 × 10 4 mg / L of simulated formation water (ie 22×10 4 mg / L NaCl aqueous solution), and a foam system was obtained after it was completely dissolved.

[0053] (2) Test of foam oil resistance and salt resistance:

[0054] ①Influence of oil content: Pour 100ml of foam system and crude oil (viscosity of 643mPa·s) into a warning blender together with a certain proportion of its volume, stir for 1min at a shear rate of 6000 rpm, and measure the foam volume The results are shown in Table 7 (oil content=volume of crude oil / volume of foam system). The oil content increases and the foam stability increases.

[0055] Table 7 Effect of oil content on foam properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com