Composite frequency modulation silencer and tuning method thereof

A muffler and composite technology, which is applied to mufflers, machines/engines, engine components, etc., can solve the problems of fixed noise control frequency band, low perforation rate, and reduced noise intensity, so as to expand the noise control frequency band, the synthesis method is simple, To achieve the effect of effective suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This application proposes a composite FM muffler, including:

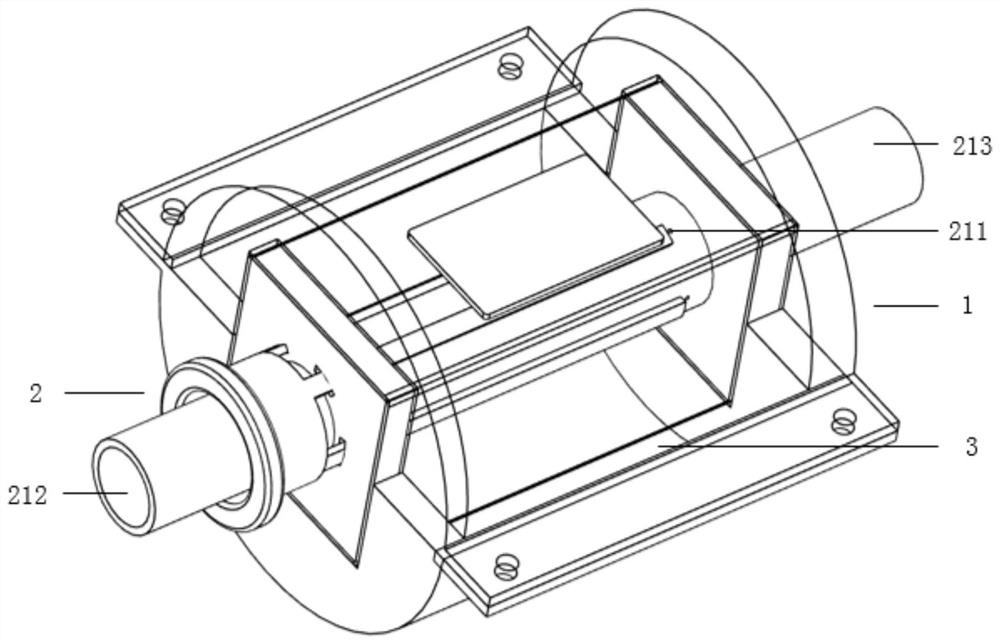

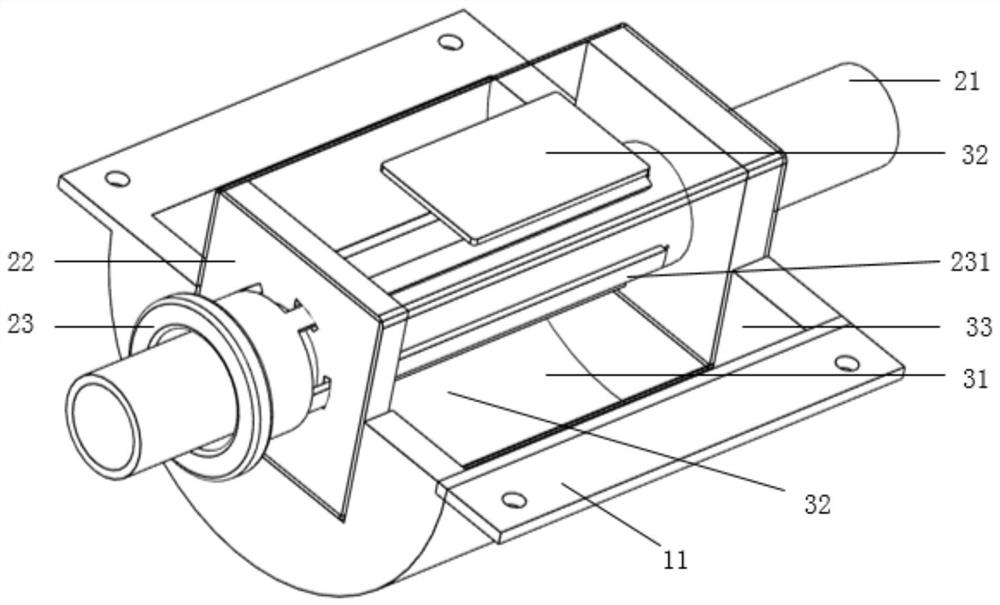

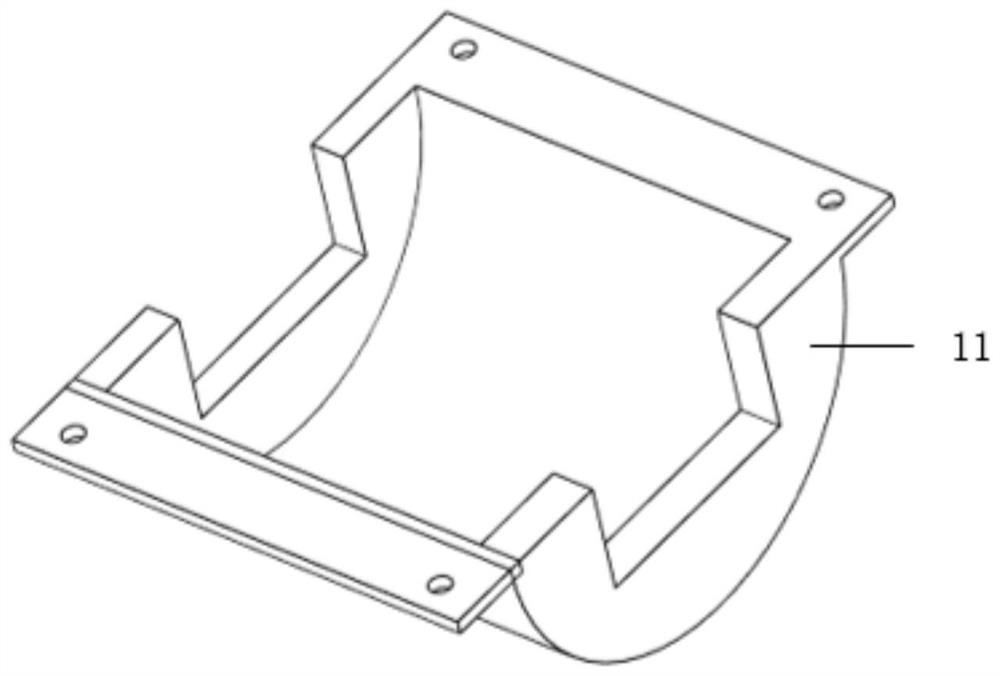

[0040] The fixing component 1 is used to ensure the sealing of the cointegration chamber. The fixing component 1 includes two shells 11 connected by flanges. The shells 11 are semi-cylindrical, and the upper and lower surfaces of the shells 11 are oppositely provided with grooves. The shell 11 is provided with a cavity, and the micro-perforated component 2 is arranged in the cavity. .

[0041] The micro-perforation assembly 2 includes a micro-perforation tube 21, at least two fixing plates 22 and a baffle plate 23, the micro-perforation assembly 2 is fixed in the fixing assembly 1, and the fixing plate 22 is arranged on the outside of the micro-perforation tube 21 and is located on the fixing plate 22 The micro-perforated tubes 21 in between are equidistantly provided with multiple columns of through holes 211, and the baffle plate 23 slides through the fixing plate 22 and is arranged on the outside of the ...

Embodiment 2

[0054] The difference between this embodiment and the first embodiment is that in step S5 of the tuning method, by adjusting the driving voltage of the piezoelectric vibrator 32 , the equivalent stiffness of the film in step S4 can be adjusted, and the frequency can be tuned. Such as Image 6 As shown, when the voltage increases from 0V to 300V, the stiffness of the film increases accordingly, the anti-resonance point moves to the high-frequency region, the coupling effect of structural resonance and acoustic resonance weakens, and the first-order anechoic peak shifts from 180Hz to 275Hz. The amount of displacement is 95Hz, and the amount of noise reduction is increased. The second-order muffler peak is shifted from 520Hz to 655Hz, and the offset is 135Hz, and the muffler drops greatly. Other technical features and working principles of this embodiment are the same as those of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perforation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com