System and method for laser processing of super-hydrophobic surface

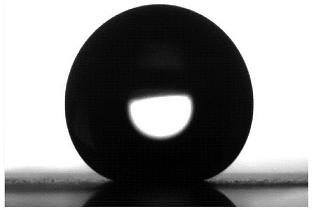

A super-hydrophobic surface and laser processing technology, which is applied to the device for coating liquid on the surface, special surface, pre-treated surface, etc., can solve the cumbersome processing process, limited hydrophobicity of Teflon surface, and no Teflon coating Problems such as surface hydrophobic modification equipment and methods, to achieve good processing effect, corrosion prevention, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

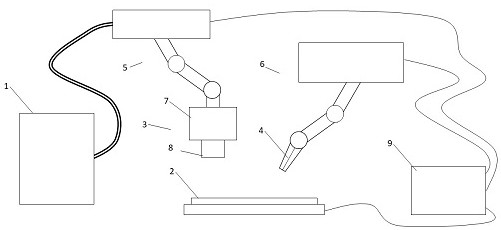

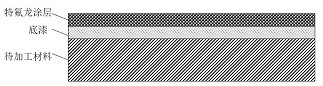

[0033] Such as figure 1 As shown, a system for laser processing superhydrophobic surfaces, including a laser 1, a rotary station 2, a laser galvanometer module 3, a spraying module 4, an irradiation manipulator module 5 and a spraying manipulator module 6;

[0034] The laser 1 is connected to the laser galvanometer module 3, and the laser galvanometer module 3 is used to provide laser out-of-focus irradiation and laser scribing to the surface of the material to be processed placed on the rotary station 2; The surface of the material to be processed on the surface provides primer spraying and Teflon coating spraying; the laser galvanometer module 3 is installed on the irradiation manipulator module 5, the spraying module 4 is installed on the spraying manipulator module 6, and the rotary station 2 It can drive the material to be processed placed on the rotating station 2 to rotate horizontally around the center of the rotating station 2; the irradiation manipulator module 5, th...

Embodiment 2

[0053] This embodiment further improves the present invention.

[0054] A third mechanical arm is also installed. The third mechanical arm is equipped with a purge module, which can blow out compressed air. When performing defocused irradiation, use the third mechanical arm to perform synchronous purge on the irradiation position to reduce the temperature during irradiation. , and at the same time improve the volatilization effect of the coating solvent; when the material is irradiated, a very thin layer of material on the surface will soften and melt. Roughening works better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com