Lime slaking tank capable of removing deposition at tank bottom without shutdown and working method of lime slaking tank

A technology for digestion tanks and tank bottoms, applied in cleaning methods and appliances, chemical instruments and methods, separation methods, etc., can solve problems such as blockage of emptying ports, easy deposition of impurities at the bottom of tanks, and the need to shut down for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

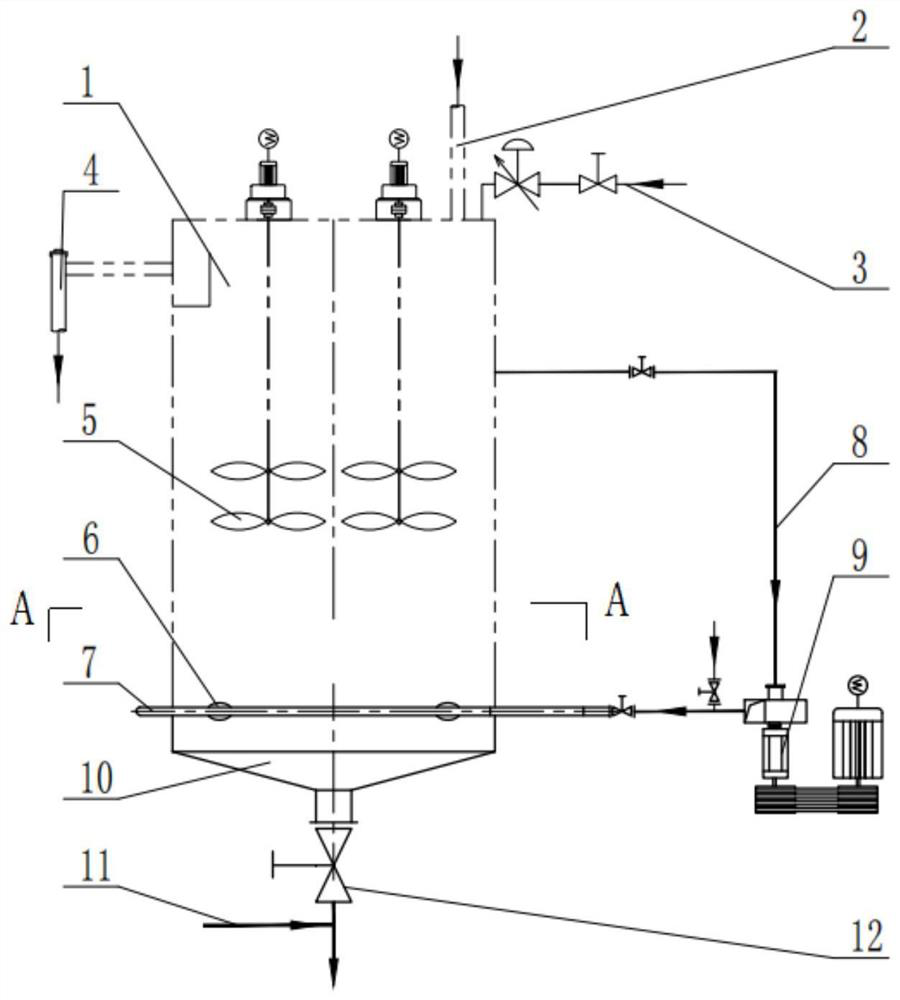

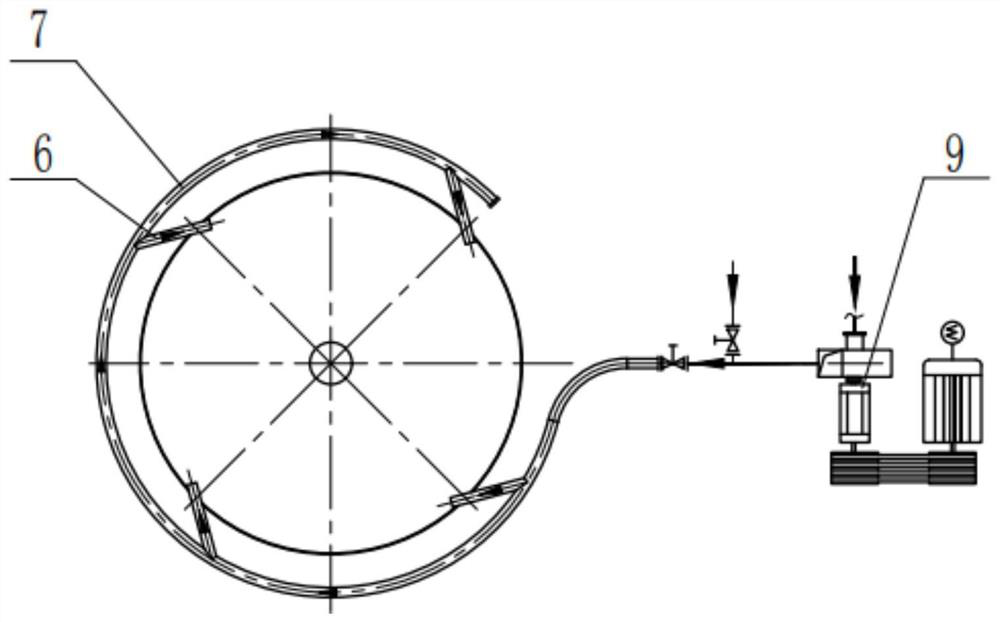

[0028] A lime digestion tank capable of removing deposits at the bottom of the tank without stopping the machine, comprising a digestion tank body 1 and an agitator 5, a ring pipe 7 is arranged at the lower part of the digestion tank body 1, and several Nozzles 6, several nozzles 6 are sprayed in a tangential direction, the liquid sprayed by several nozzles 6 forms a swirling flow at the bottom of the digestion tank, the ring pipe 7 is connected to a circulating slurry pump 9, and the circulating slurry pump 9 passes through The pipeline is connected to the upper part of the tank body 1 of the digestion tank.

[0029] When the raw lime digestion tank is working, because the lime raw material contains a certain proportion of mud and sand, the mass is large, resulting in a large amount of sediment at the bottom of the tank, resulting in blockage of the emptying pipe. The effective volume gradually becomes smaller and needs to be shut down for processing. After the slurry circul...

Embodiment 2

[0031] A lime digestion tank capable of removing deposits at the bottom of the tank without stopping the machine, comprising a digestion tank body 1 and an agitator 5, a ring pipe 7 is arranged at the lower part of the digestion tank body 1, and several Nozzles 6, several nozzles 6 are sprayed in a tangential direction, the liquid sprayed by several nozzles 6 forms a swirling flow at the bottom of the digestion tank, the ring pipe 7 is connected to a circulating slurry pump 9, and the circulating slurry pump 9 passes through The pipeline is connected to the upper part of the tank body 1 of the digestion tank. The bottom of the digestion tank body 1 is conical, the conical bottom is an emptying port, and the emptying port is connected to an emptying pipe 12 .

[0032] Since the bottom of the digester tank body 1 has been changed to a pile-shaped tank bottom 10, after the swirl flow is formed, after the mud and sand are agitated by the swirl flow, the heavier impurities will swi...

Embodiment 3

[0034] A lime digestion tank capable of removing deposits at the bottom of the tank without stopping the machine, comprising a digestion tank body 1 and an agitator 5, a ring pipe 7 is arranged at the lower part of the digestion tank body 1, and several Nozzles 6, several nozzles 6 are sprayed in a tangential direction, the liquid sprayed by several nozzles 6 forms a swirling flow at the bottom of the digestion tank, the ring pipe 7 is connected to a circulating slurry pump 9, and the circulating slurry pump 9 passes through The pipeline is connected to the upper part of the tank body 1 of the digestion tank. A backwashing device 11 is also included, and the backwashing device 11 is connected to an emptying pipe 12 at the bottom of the digestion tank body 1 .

[0035] Large pieces of material in the mud and sand can easily cause blockage of the emptying pipe 12. A backwashing device 11 is installed on the upper part of the emptying pipe 12. Through the backwashing device 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com