Production device and production method of p-xylene

A technology for p-xylene and production equipment, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve problems such as environmental pollution, reduce back-mixing, reduce equipment investment and floor space, The effect of reducing the operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The production device of p-xylene, including xylene fractionation unit, adsorption separation unit and isomerization reaction unit;

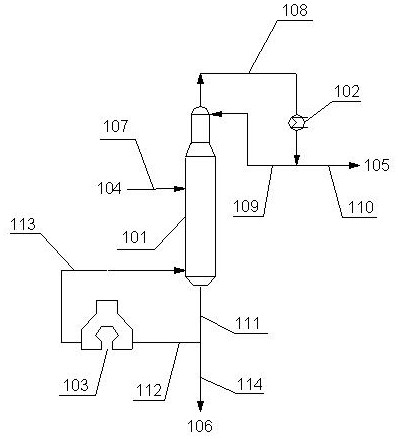

[0058] Described xylene fractionation unit such as figure 1 Shown, including xylene tower 101, heat exchanger I 102 and xylene reboiler 103, also includes the C 8 Aromatic hydrocarbon mixture raw material 104 is fed to the feed line 107 of the xylene tower 101; the tower top discharge is sent to the pipeline 108 of the heat exchanger I102; The pipeline 109 of the toluene tower; another part of the tower top discharge 105 after heat exchange by the heat exchanger I102 is sent to the pipeline 110 of the adsorption separation feed; a part of the tower bottom material 111 is sent to the feed of the tower bottom reboiler 103 Pipeline 112; The pipeline 113 that is used to circulate the tower bottom material heated by the tower bottom reboiler 103 back to the xylene tower; Another part of the tower bottom material 106 is discharged from the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com