Oily polycrystalline diamond grinding and polishing solution and production and preparation process thereof

A polycrystalline diamond and preparation technology, which is applied in the field of oily polycrystalline diamond grinding and polishing liquid and its production and preparation technology, can solve the problems of low mixing efficiency, poor lubrication ability, grinding body scratches, etc., and achieve fast mixing speed , safe and convenient to use, the effect of raw material dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

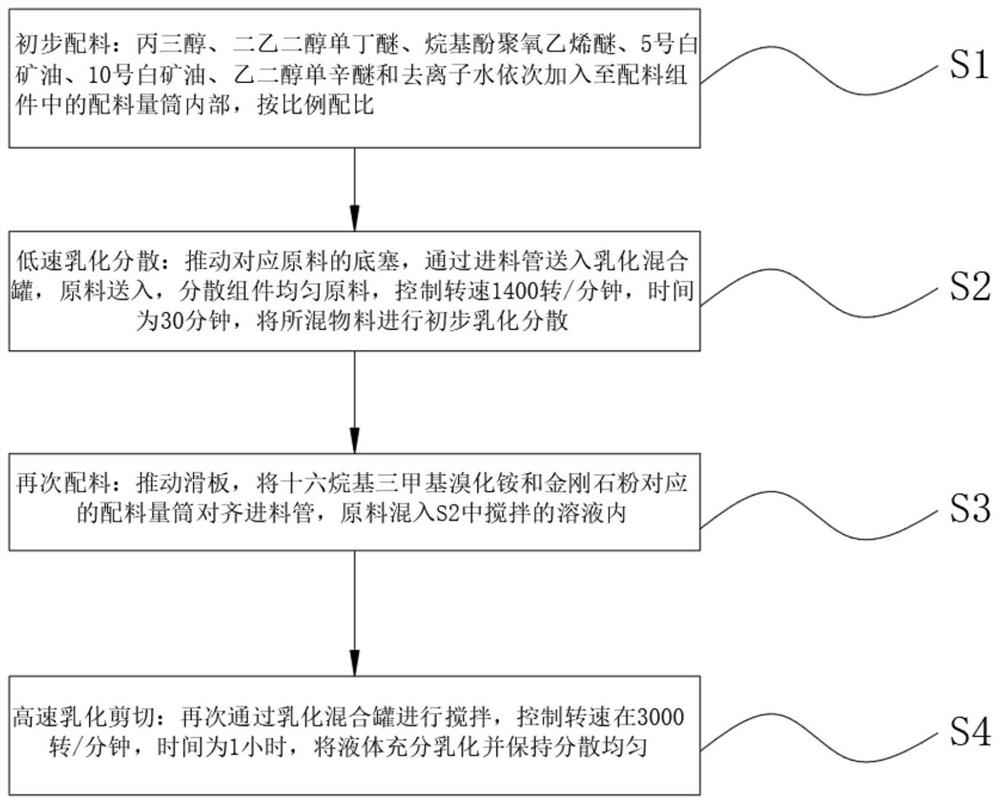

[0043] Embodiment 1: as figure 1 As shown, the present invention provides a kind of oily polycrystalline diamond grinding and polishing liquid and its production preparation process technical scheme, a kind of production preparation process of oily polycrystalline diamond grinding and polishing liquid, comprising the following steps:

[0044] S1: Preliminary ingredients: glycerol, diethylene glycol monobutyl ether, alkylphenol polyoxyethylene ether, No. 5 white mineral oil, No. 10 white mineral oil, ethylene glycol monooctyl ether and deionized water were added to the The inside of the batching cylinder 211 in the batching assembly 2 is proportioned;

[0045]S2: Low-speed emulsification and dispersion: Push the bottom plug 212 corresponding to the raw material, and send it into the emulsification mixing tank 1 through the feed pipe 202, and the raw material is sent in, and the dispersion component 3 is uniform in the raw material. The control speed is 1400 rpm, and the time is...

Embodiment 2

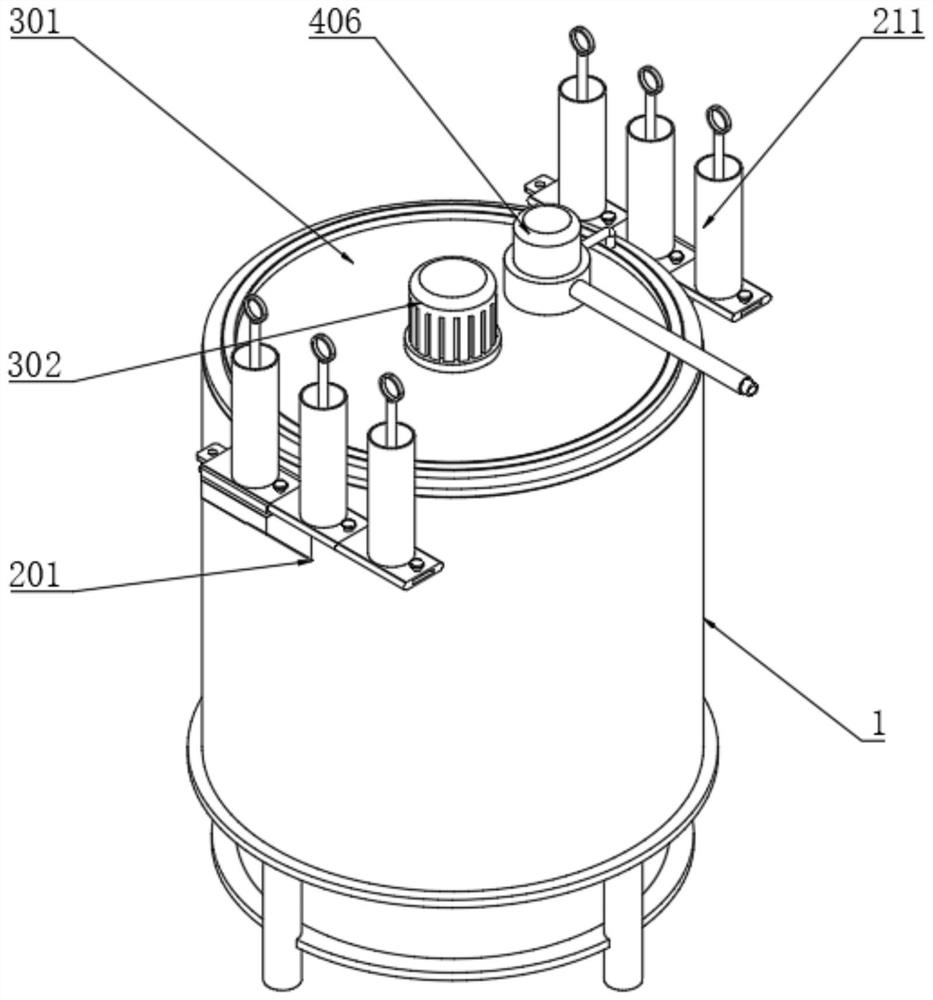

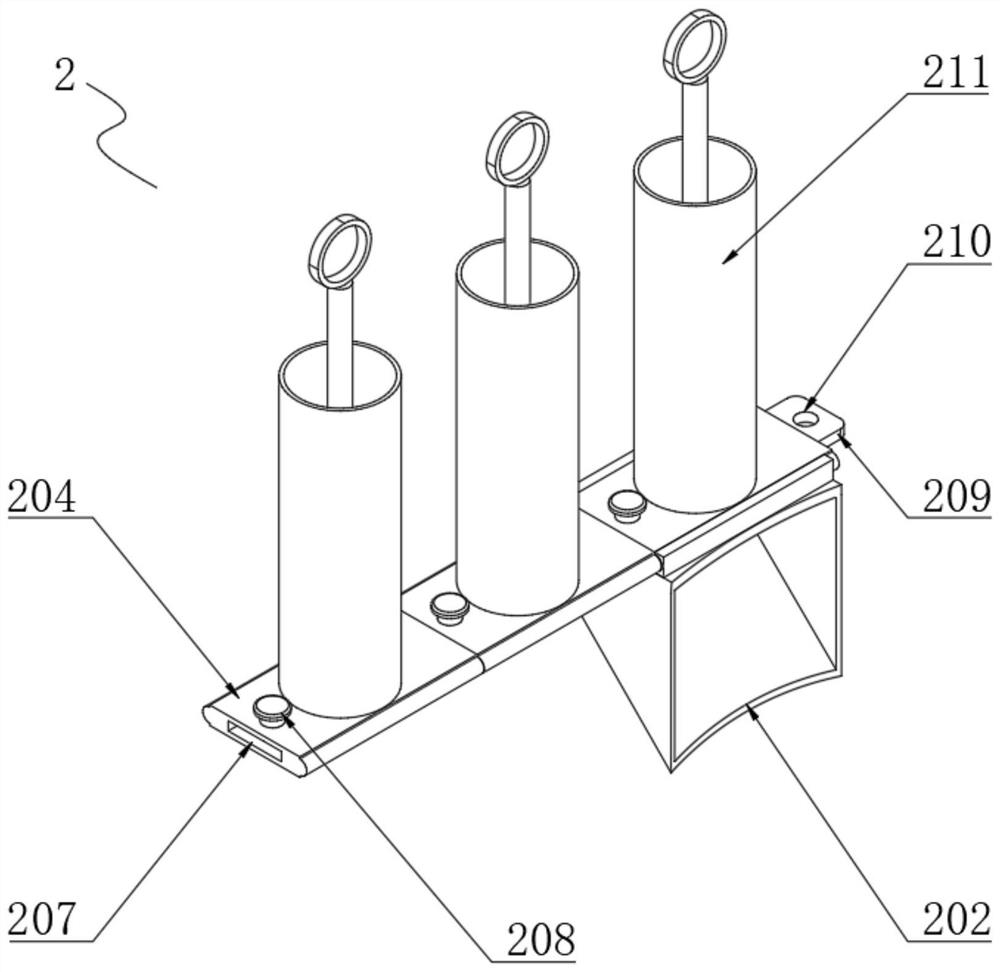

[0049] Embodiment 2: as Figure 2-4 As shown, the two ends of the emulsification mixing tank 1 are equipped with a batching assembly 2, and the batching assembly 2 includes a feed port 201, a feed pipe 202, a slide rail 203, a slide plate 204, a docking hole 205, a rubber sheet 206, a docking groove 207, Pin 208, docking plate 209, pin hole 210, batching measuring cylinder 211, bottom plug 212, top plug 213, fan-shaped hole 214 and pull rod 215;

[0050] The feed port 201 is set on the side of the top of the emulsification mixing tank 1, and a feed pipe 202 is welded on one side of the feed port 201. A slide rail 203 is fixedly installed on the top surface of the feed pipe 202, and a slide plate 204 is slidably installed inside the slide rail 203. The length of the rail 203 is equal to the length of the slide plate 204. The inner wall of the slide rail 203 and the outside of the slide plate 204 are smooth arc-shaped surfaces, which is convenient for the slide plate 204 to slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com