Metal product with metal antibacterial composite film on surface and manufacturing method thereof

A technology for metal products and manufacturing methods, which is applied in the coating process of metal materials, household appliances, household appliances, etc., can solve the adverse effects of wear resistance and corrosion resistance of stainless steel products, and the unsatisfactory corrosion resistance and wear resistance. , antibacterial performance restriction and other problems, to achieve the effect of easy washing and maintenance, excellent antibacterial performance, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

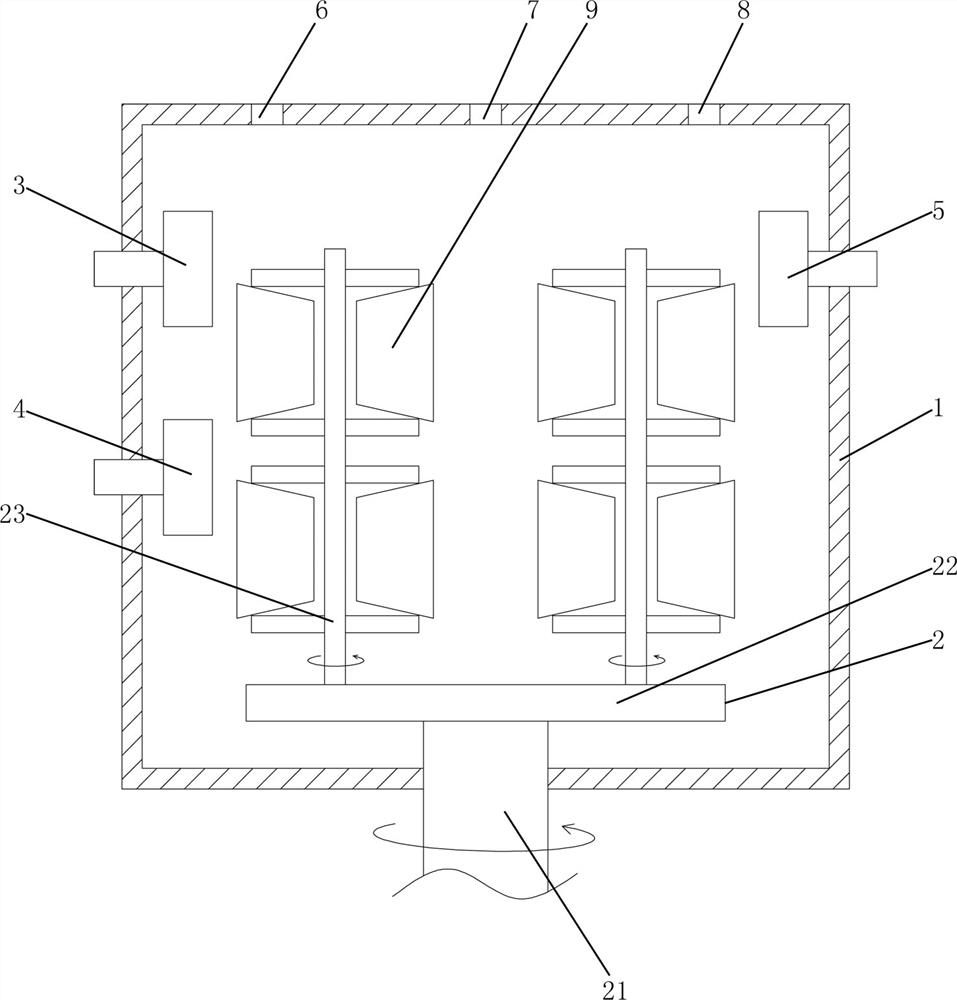

Image

Examples

Embodiment 1

[0037] In this embodiment, the metal product with the metal antibacterial composite film on the surface includes a metal product substrate, the surface of the metal product substrate is covered with an inner metal nitride film layer, and the inner metal nitride film layer is covered with an intermediate metal nitride film layer, the middle metal nitride film layer is coated with an outer metal nitride film layer. In this embodiment, the material of the metal product substrate is stainless steel; the inner metal nitride film layer is a Cr-N film layer; the middle metal nitride film layer is an Ag-N film layer; the outer metal nitride film layer is a Ti-N film layer layer. The inner metal nitride film layer, the middle metal nitride film layer and the outer metal nitride film layer are combined together to form a metal antibacterial composite film.

[0038] The basic steps of the manufacturing method of the above-mentioned metal product with metal antibacterial composite film o...

Embodiment 2

[0067] The material of the metal product substrate in this embodiment is the same as that of Embodiment 1, and the equipment and process steps adopted are also the same as Embodiment 1.

[0068] The difference between the metal product of this embodiment and Embodiment 1 is that in the metal antibacterial composite film, the inner metal nitride film layer is a Ti-N film layer, the middle metal nitride film layer is a Sn-Cu-N film layer, and the outer nitrogen film layer is a Ti-N film layer. The metallization film layer is a Cr-N film layer.

[0069] The manufacturing method of this embodiment differs from that of Embodiment 1 in that: the material of the inner layer metal target is titanium, the material of the middle layer metal target is a combination of tin and copper (where tin is 25%wt, copper is 75%wt), and the outer The material of the first-layer metal target is chromium; in step (2), argon gas is introduced to clean the metal product substrate 9 for 15 minutes; in st...

Embodiment 3

[0082] The material of the metal product substrate in this embodiment is the same as that of Embodiment 1, and the equipment and process steps adopted are also the same as Embodiment 1.

[0083] The difference between the metal product of this embodiment and Example 1 is that in the metal antibacterial composite film, the inner metal nitride film layer is a Ti-N film layer; the middle metal nitride film layer is a Sn-Cu-N film layer; the outer nitrogen film layer is a Ti-N film layer; The metallization film layer is a Zr-N film layer.

[0084] The manufacturing method of this embodiment differs from that of Embodiment 1 in that: the material of the inner layer metal target is titanium, the material of the middle layer metal target is a combination of tin and copper (where tin is 30%wt, copper is 70%wt), and the outer The material of the layered metal target is zirconium; in step (2), pass argon gas to clean the metal product substrate 9 for 30 minutes; in step (3), the time fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com