Flexible pressure sensing structure and flexible pressure sensor

A pressure and flexibility technology, applied in the field of flexible sensors, can solve the problems of reduced sensitivity and poor stability, and achieve the effects of increased sensitivity, strong scalability, and simple design principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A novel flexible pressure sensing structure prepared by the following method:

[0035] 1) The 6 μm thick copper foil was hot-pressed on the polydimethylsiloxane film by the lamination method, and the interdigitated electrode array was processed by the laser direct writing process.

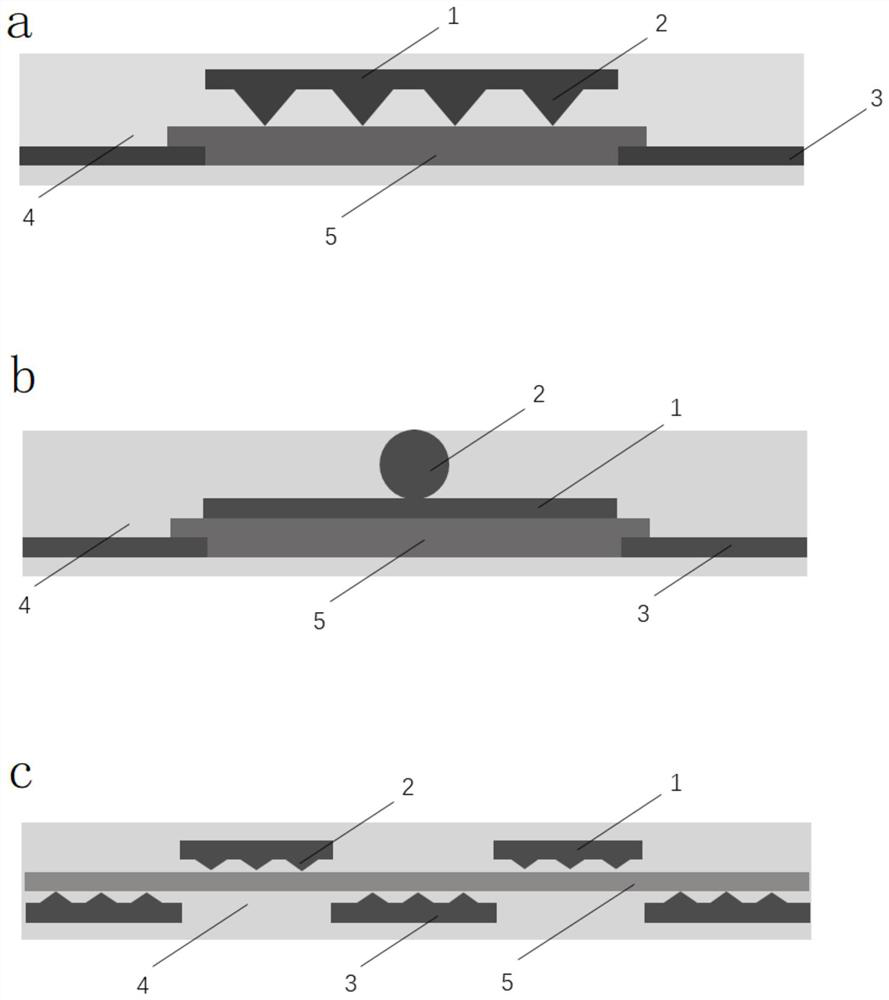

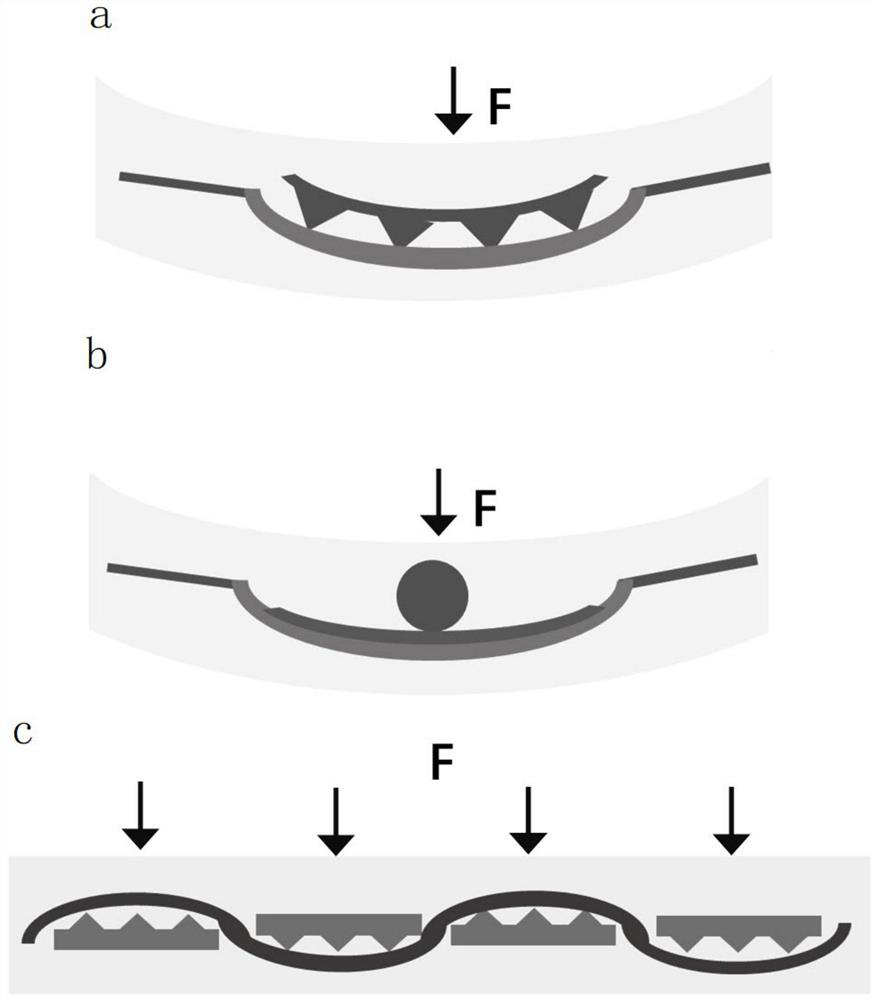

[0036] 2) Under the condition of 3000rmp / 30s, spin-coat the conductive carbon oil on the silicon-based inverted pyramid template. When the carbon film is semi-cured, attach the conductive copper foil to the carbon film, and peel off the carbon film after curing, thus , interdigitated electrode pairs surface-integrated miniature conductive pyramid arrays, see figure 1 in c.

[0037] 3) Under the condition of 3000rmp / 60s, spin-coat the conductive carbon oil on the PVA film, and heat it at 80°C for 60s. After the conductive film is cured, use the water transfer method to transfer the conductive film to the surface of the PI film, and then use the laser to write directly patterning of conducti...

Embodiment 2

[0042] A novel flexible pressure sensing structure prepared by the following method:

[0043] 1) The 6 μm thick copper foil is hot-pressed on the polydimethylsiloxane film by the lamination method, and the copper foil is processed by laser direct writing to form an arrayed ring-shaped lower electrode and an upper electrode. The upper electrode is smaller in diameter than the lower electrode. surface electrode.

[0044] 2) The patterned PI film after laser direct writing is used as a mask and attached to the lower electrode.

[0045] 3) Under the condition of 3000rmp / 60s, spin-coat the conductive carbon oil on the lower electrode, and cure it at 80°C for 30s. When the film is semi-cured, align and bond the upper electrode array on the conductive film; A flexible pressure-sensing structure without microstructures is formed.

[0046]The flexible pressure sensing structure is used for further processing. After the electrode leads, the Ecoflex solution is spin-coated at 5000rmp / 3...

Embodiment 3

[0049] A novel flexible pressure sensing structure prepared by the following method:

[0050] 1) Hot-press 6μm thick copper foil on the polydimethylsiloxane film by lamination method, and use laser direct writing copper foil to form an arrayed ring-shaped lower electrode and upper electrode. The diameter of the upper electrode is smaller than that of the lower electrode surface electrodes.

[0051] 2) Under the condition of 3000rmp / 30s, spin-coat the conductive carbon oil on the silicon-based inverted pyramid template. When it is semi-cured, attach the copper foil electrode to the carbon film, and peel it off after curing to form a film, thus obtaining surface integration. Electrodes with micro-pyramid structures, see figure 1 in a.

[0052] 3) Use the patterned PI film after laser direct writing as a mask, and attach it to the lower arrayed electrode, apply conductive carbon oil to the lower electrode by spin coating, and cure at 80°C for 30s, and wait until the film is hal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com