Solar backboard with high barrier property

A solar back sheet and high barrier technology, applied in the field of solar back sheets, can solve the problems of poor water vapor barrier performance, etc., and achieve the effects of easy operation, simple manufacturing process, and prevention of water vapor intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

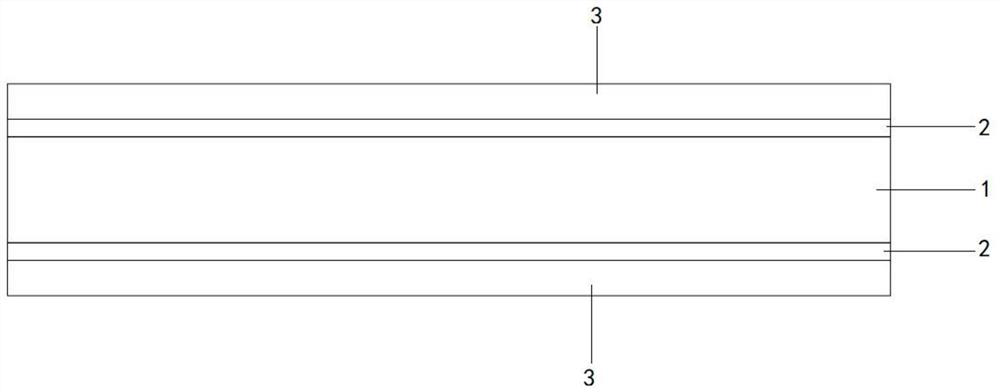

[0022] A solar backsheet with high barrier properties, comprising a PET substrate layer 1, an adhesive layer 2 arranged on both sides of the PET substrate layer 1 and a barrier layer 3 arranged on the other side of the adhesive layer 2, the PET substrate The thickness of layer 1 is 120 μm; the adhesive layer 2 is an epoxy resin adhesive layer or acrylic resin adhesive layer, and its thickness is 2 μm; the thickness of barrier layer 3 is 15 μm; among them,

[0023] In parts by weight, the barrier layer 3 is prepared from the following raw materials: 45 parts of long carbon chain nylon, 18 parts of nano-scale inorganic powder and 2 parts of heat stabilizer; the preparation method of barrier layer 3 is: put each raw material into a high-speed mixer Inside, the temperature was raised to 380°C, stirred for 2 hours, and then extruded by an extruder to prepare the barrier layer 3; the processing temperature of the extruder was 180°C.

[0024] Among them, the long carbon chain nylon i...

Embodiment 2

[0026] A solar backsheet with high barrier properties, comprising a PET substrate layer 1, an adhesive layer 2 arranged on both sides of the PET substrate layer 1 and a barrier layer 3 arranged on the other side of the adhesive layer 2, the PET substrate The thickness of layer 1 is 180 μm; the adhesive layer 2 is an epoxy resin adhesive layer or acrylic resin adhesive layer, and its thickness is 3 μm; the thickness of barrier layer 3 is 22 μm; among them,

[0027] In parts by weight, the barrier layer 3 is prepared from the following raw materials: 50 parts of long carbon chain nylon, 20 parts of nano-scale inorganic powder and 3 parts of heat stabilizer; the preparation method of the barrier layer 3 is: put each raw material into a high-speed mixer Stir for 4 hours and extrude with an extruder to prepare the barrier layer 3; the processing temperature of the extruder is 185°C.

[0028] Among them, the long carbon chain nylon is PA1212; the average particle size of the nanosca...

Embodiment 3

[0030] A solar backsheet with high barrier properties, comprising a PET substrate layer 1, an adhesive layer 2 arranged on both sides of the PET substrate layer 1 and a barrier layer 3 arranged on the other side of the adhesive layer 2, the PET substrate The thickness of layer 1 is 300 μm; the adhesive layer 2 is an epoxy resin adhesive layer or acrylic resin adhesive layer, and its thickness is 3 μm; the thickness of barrier layer 3 is 24 μm; among them,

[0031] In parts by weight, the barrier layer 3 is prepared from the following raw materials: 40 parts of long carbon chain nylon, 20 parts of nano-scale inorganic powder and 2.5 parts of heat stabilizer; the preparation method of barrier layer 3 is: put each raw material into a high-speed mixer Stir for 4 hours and extrude with an extruder to prepare the barrier layer 3; the processing temperature of the extruder is 190°C.

[0032] Among them, the long carbon chain nylon is PA1212; the average particle size of the nano-scal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com