Electrostatic chuck for high bias radio frequency (RF) power application in plasma processing chamber

An electrostatic chuck, chamber technology, applied in the direction of holding devices, circuits, discharge tubes, etc. where electrostatic attraction is applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

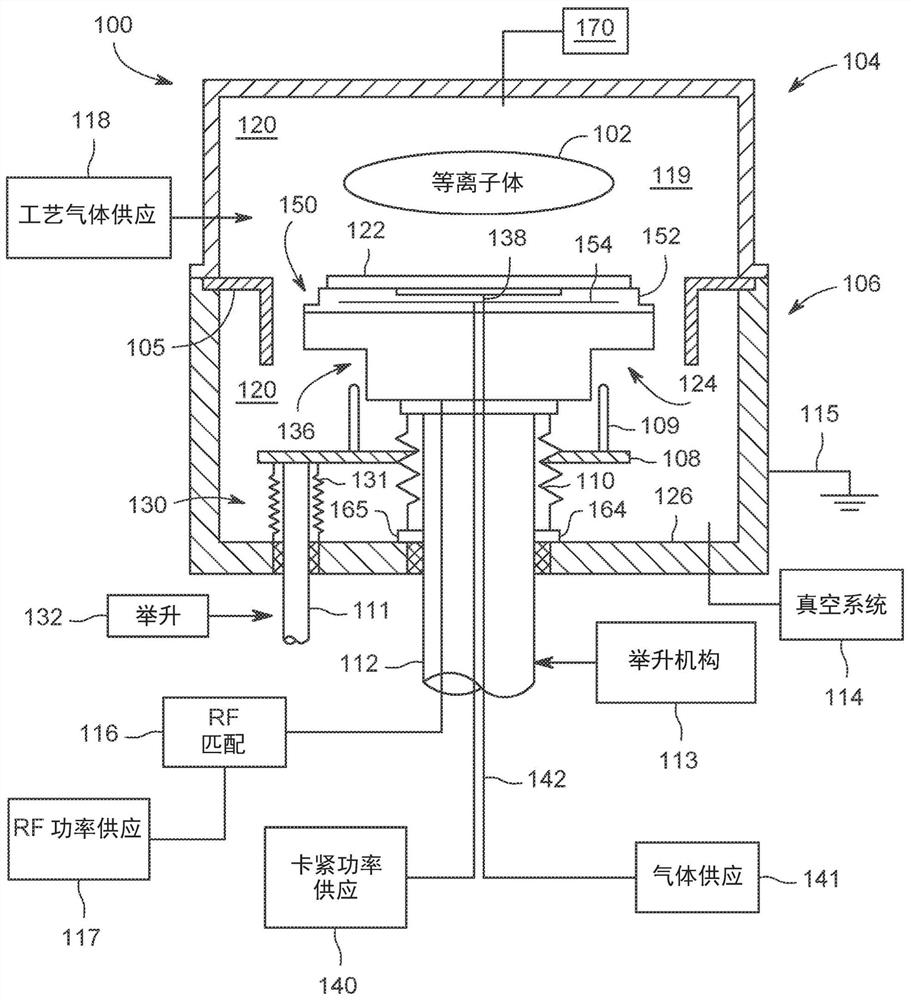

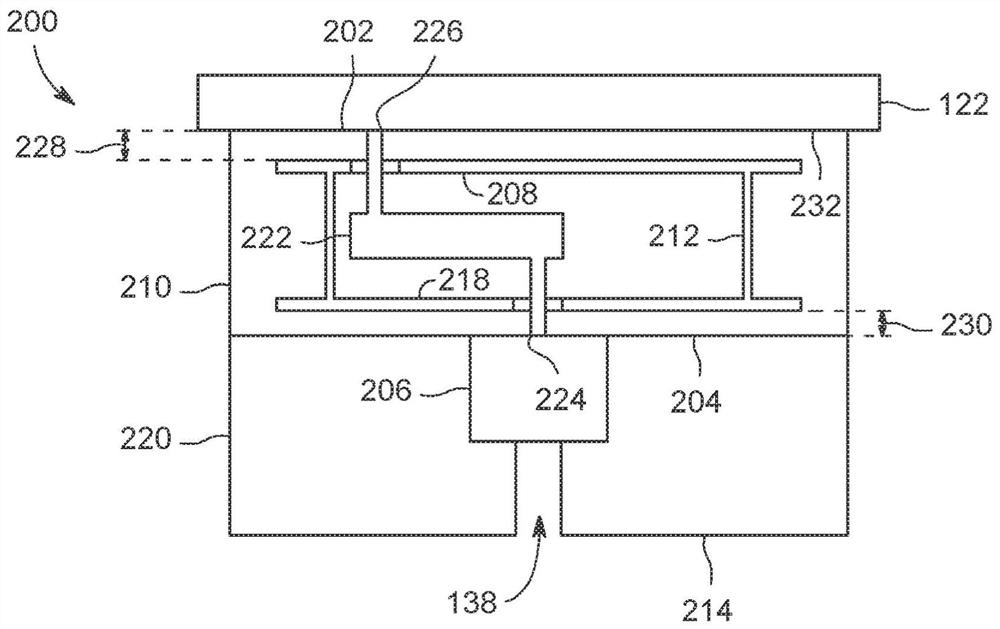

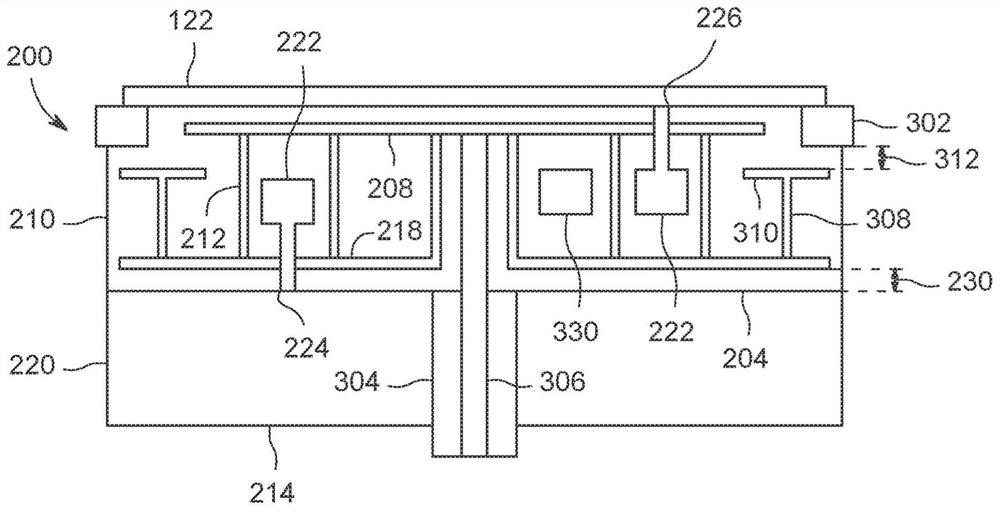

[0014] Examples of electrostatic chucks for use in substrate processing chambers are provided herein. An electrostatic chuck includes a dielectric plate having a support surface to support a substrate. The dielectric plate is arranged on the cooling plate. In some embodiments, one or more gas channels extend from the bottom surface of the electrostatic (eg, the bottom surface of the cooling plate) to the top surface of the electrostatic chuck (eg, the top surface of the dielectric plate). The one or more gas channels are configured to provide a backside gas, such as nitrogen (N) or helium (He), to the top surface of the electrostatic chuck to act as a heat transfer medium.

[0015] In some embodiments, an RF power source is coupled to the cooling plate and configured to provide a negative bias voltage to the processed substrate. As RF power is applied to the cooling plate, the peak-to-peak voltage (Vpp) on the cooling plate and Vpp on the substrate differs depending on the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com