Hierarchical feed tower

A feed tower and hierarchical technology, applied in the field of feed towers, can solve problems such as difficulty in discharging, affecting the stability of discharge, and affecting the service life of the tank, so as to improve the smoothness of the flow field, improve the safety of assembly, and reduce the inner wall The effect of attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

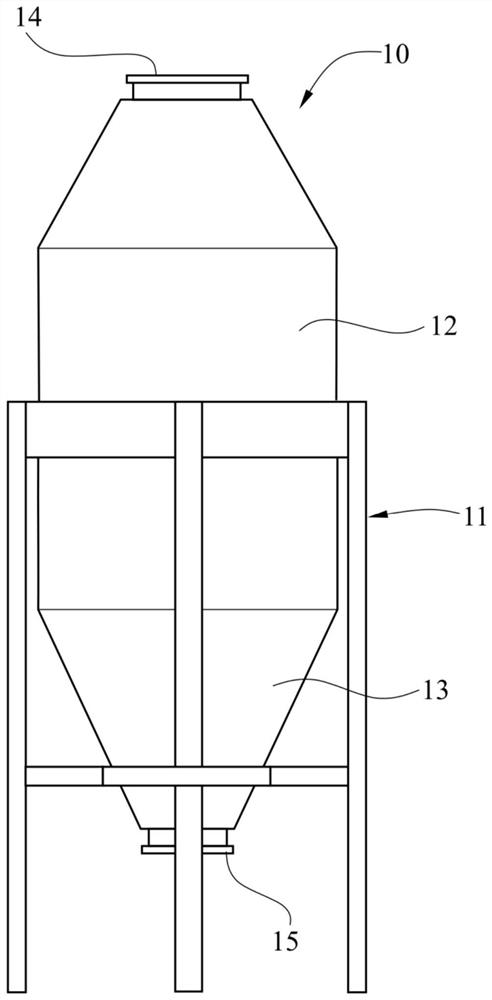

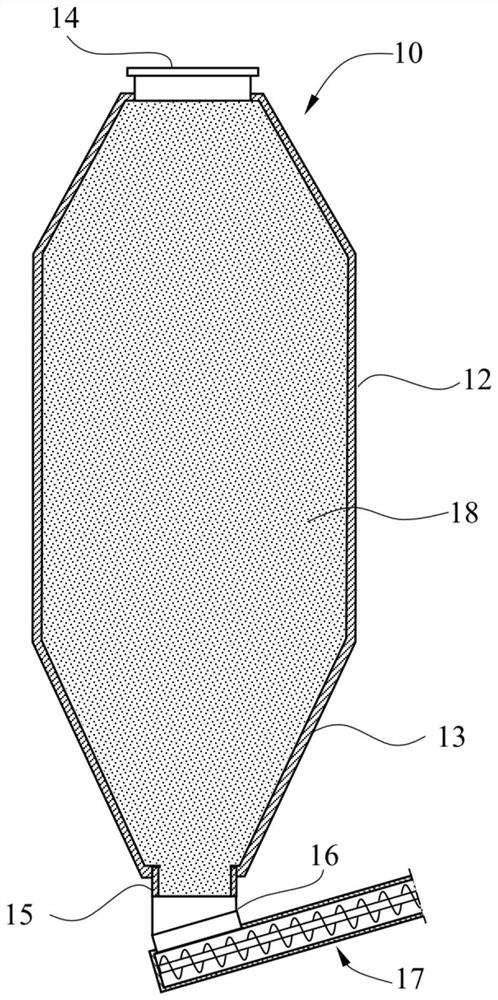

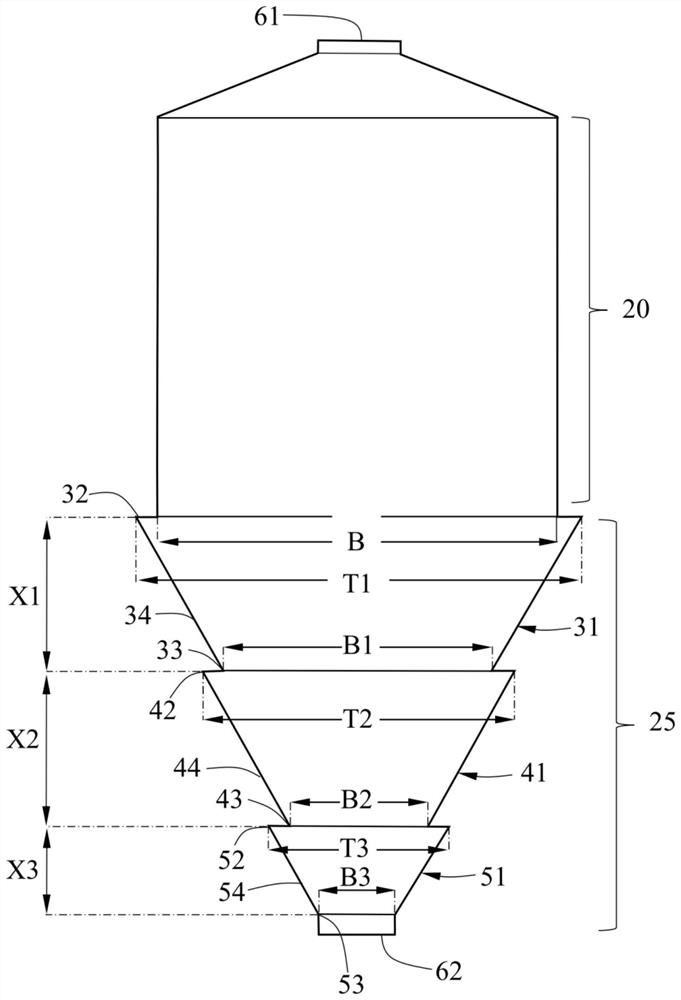

[0021] like Figure 3 to Figure 4 , the feed tower of the present invention comprises a bucket body 20, a layered conical portion 25 connected under the barrel body 20, an upper feed inlet 61 located at the top of the barrel body 20, and a layered conical portion located at the top of the barrel body 20. The discharge opening 62 at the bottom of 25. The barrel body 20 and the hierarchical conical portion 25 are hollow inside and communicate with each other. Feed is filled into the barrel body 20 and the conical portion 25 through the upper feeding port 61, and the feed passes through the lower A discharge valve 64 of the discharge port 62 is distributed to the conveying system 65 and then distributed to respective feeding troughs for the livestock in the farm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com