Preparation method of herba houttuyniae and rice fermentation product filtrate composition

The technology of a fermented product, Houttuynia cordata, is applied in drug combinations, skin care preparations, medical preparations containing active ingredients, etc. It can solve the problems of insufficient mildness and large chemical pollution, and achieve skin elasticity and smoothness. Inhibit the activity of oxygen free radicals and delay skin aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

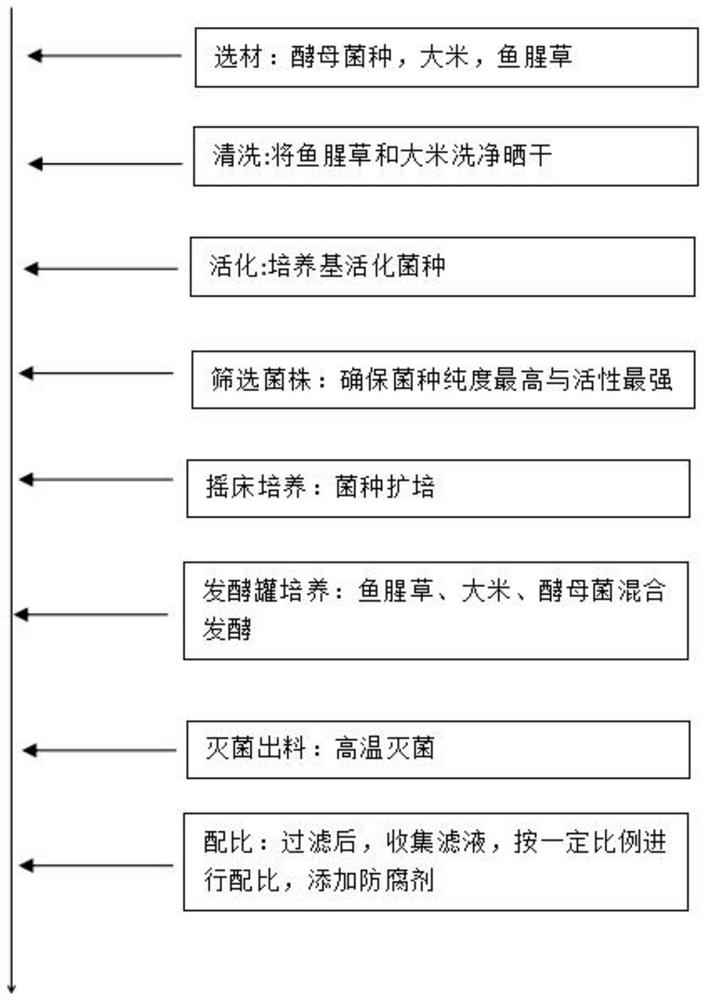

[0033] A kind of preparation method of Houttuynia cordata rice fermentation product filtrate composition, its technological process is as follows figure 1 shown, including the following steps:

[0034] 1. Purified water for domestic use meets 38 items of pure water testing standards. Wash and dry Houttuynia cordata and rice, and the water content is less than 5%.

[0035] 2. Grind the dried Houttuynia cordata and rice with an 800Y high-speed multifunctional grinder. Screen the Houttuynia cordata powder and rice flour with a 80-mesh sieve, and collect the parts that pass through the sieve respectively.

[0036] 3. The mixed fermented liquid comprises the following components in mass percentage: 3-10% of Houttuynia cordata powder, 3-10% of rice flour, 2-5% of yeast liquid, and the rest is water. Mix Houttuynia cordata powder, rice flour and water first, then sterilize and cool down to 28-32°C for later use.

[0037] 4. Inoculate the yeast activated by the shaker into the cult...

Embodiment 2

[0040] 1. Purified water for domestic use meets 38 items of pure water testing standards. Wash and dry Houttuynia cordata and rice with a water content of 1-5%.

[0041] 2. Grind the dried Houttuynia cordata and rice with an 800Y high-speed multifunctional grinder. Screen the Houttuynia cordata powder and rice flour with a 80-mesh sieve, and collect the parts that pass through the sieve respectively.

[0042] 3. The mixed fermented liquid comprises the following components in mass percentage: Houttuynia cordata powder 4-8%, rice flour 4-8%, yeast liquid 2-5%, and the rest is water. Mix Houttuynia cordata powder, rice flour and water first, then sterilize and cool down to 28-32°C for later use.

[0043] 4. Inoculate the yeast activated by the shaker into the culture medium for fermentation. The fermentation conditions are as follows: the pH range is 5.7-6.5, the fermentation temperature is 29-32° C., the shaker speed is 120-160 rpm, and the fermentation time is 12-16 hours. ...

Embodiment 3

[0046] 1. Purified water for domestic use meets 38 items of pure water testing standards. Wash and dry Houttuynia cordata and rice with a water content of 1-3%.

[0047] 2. Grind the dried Houttuynia cordata and rice with an 800Y high-speed multifunctional grinder. Screen the Houttuynia cordata powder and rice flour with a 80-mesh sieve, and collect the parts that pass through the sieve respectively.

[0048] 3. The mixed fermented liquid comprises the following components in mass percentage: Houttuynia cordata powder 4-7%, rice flour 4-7%, yeast liquid 3-5%, and the rest is water. Mix Houttuynia cordata powder, rice flour and water first, then sterilize and cool down to 28-32°C for later use.

[0049] 4. Inoculate the yeast activated by the shaker into the culture medium for fermentation. The fermentation conditions are as follows: a pH range of 5.5 to 6.2, a fermentation temperature of 28 to 31° C., a shaker speed of 120 to 160 rpm, and a fermentation time of 12 to 16 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com