Biodegradable anastomosis nail and preparation method thereof

A staple and biological technology, applied in the field of medical devices, can solve problems such as pain, foreign body sensation, chronic infection, and staple residue, and achieve the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the present invention also provides a method for preparing a degradable nail body. Taking magnesium alloy as an example, the preparation process of magnesium alloy includes the following steps:

[0041] 1) Take Zn4kg, Mn3kg, Sn1kg, Ag2kg, Mg72.8kg;

[0042] 2) drying each component weighed above at a temperature of 100° C. for 2 hours;

[0043] 3) Add the dried Zn, Mn, Sn, Ag and Mg to the graphite crucible and vacuumize it, then pass in a mixed gas of BF6 and CO2 as a protective gas, and dissolve each component completely under the condition of 700°C , kept for 30min to obtain a smelting solution;

[0044] 4) Pour the smelting solution into a pre-dried graphite mold to obtain a magnesium alloy ingot;

[0045] In one case of this embodiment, taking magnesium alloy as an example, the heat treatment process of magnesium alloy includes the following steps:

[0046] 1) solid-dissolving the magnesium alloy ingot obtained in the preparation process of mag...

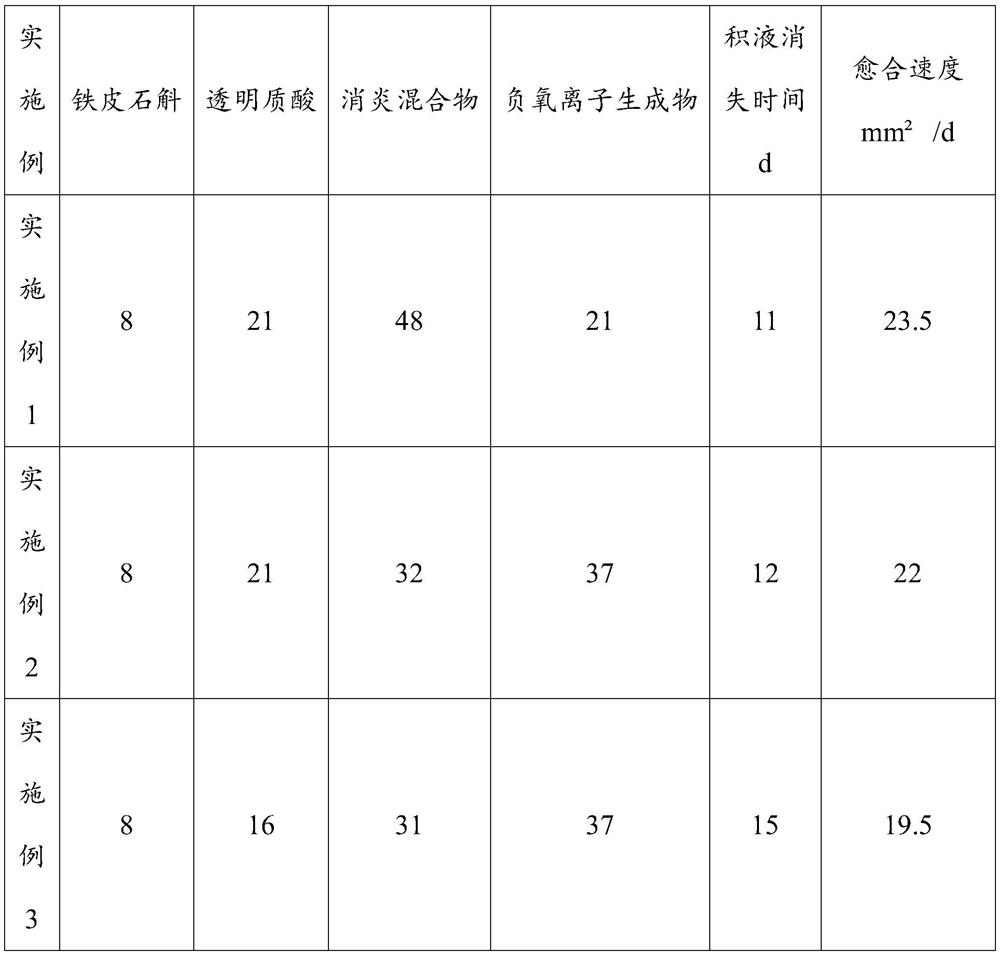

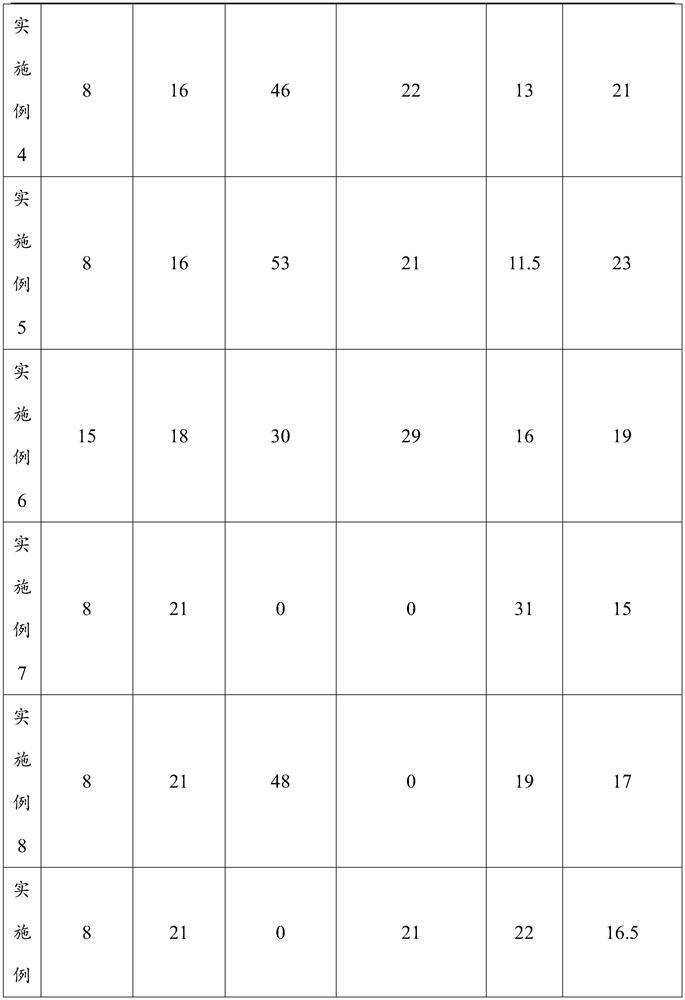

Embodiment 1

[0063] The preparation of the degradable nail body of the anastomotic staple in this embodiment includes the following steps: take Zn4kg, Mn3kg, Sn1kg, Ag2kg, Mg72.8kg, and dry it in an oven at 100°C for 1-2 hours; dry the dried Zn, Mn, Sn , Ag and Mg were added to the graphite crucible to evacuate, and after evacuation, a mixed gas of BF6 and CO2 was introduced as a protective gas. After the components were completely dissolved at 700°C, they were kept for 30 minutes; a smelting solution was obtained; the smelting solution was Pour it into a pre-dried graphite mold to obtain a magnesium alloy ingot; put the magnesium alloy ingot into solid solution at 540°C for 11 hours; put the solid-solved magnesium alloy ingot or zinc alloy into the preheated mold, The preheating temperature is 250°C, and the extruded material is formed at a temperature of 400°C to obtain a degradable staple.

[0064] The preparation of the anti-inflammatory and antibacterial layer of staples in this embod...

Embodiment 2

[0068] The preparation of the degradable nail body of the staple in this embodiment includes the following steps: take Zn4kg, Mn3kg, Sn0.6kg, Ag18kg, Mg72.8, and dry it in an oven at 100°C for 1-2 hours; dry the dried Zn, Mn , Sn, Ag and Mg were added to the graphite crucible to evacuate, and after evacuation, a mixed gas of BF6 and CO2 was introduced as a protective gas. After the components were completely dissolved at 700 ° C, they were kept for 30 minutes; a smelting solution was obtained; Pour the smelting solution into a pre-dried graphite mold to obtain a magnesium alloy ingot; solidify the magnesium alloy ingot at 540°C for 11 hours; put the solid-dissolved magnesium alloy ingot or zinc alloy into the preheated mold In this method, the preheating temperature is 250°C, and extrusion molding is performed at a temperature of 400°C to obtain degradable staples.

[0069] The preparation of the anti-inflammatory and antibacterial layer of staples in this embodiment comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com