Method for removing hexavalent chromium in chromium slag

A technology of hexavalent chromium and chromium slag, which is applied in the field of removal of hexavalent chromium in chromium slag, can solve the problems of damaging human health and polluting the environment, and achieves the effect of low price, simple operation, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

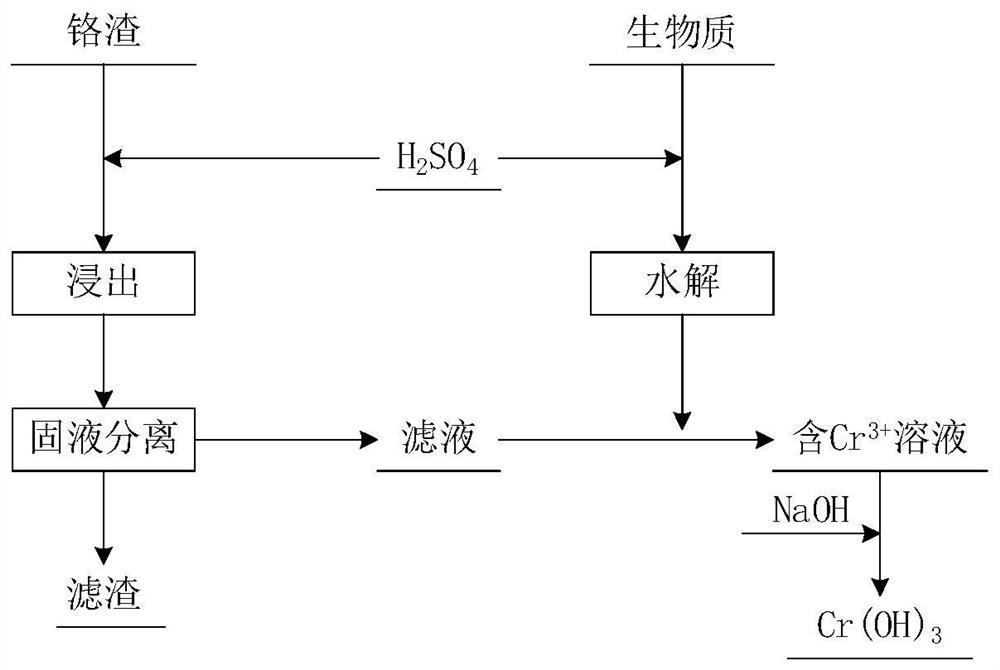

[0027] A method for removing hexavalent chromium in chromium slag, specific operation steps:

[0028] (1) Grind the particle size of the chromium slag to be treated to 75um, weigh 30g of chromium slag containing hexavalent chromium, put 150ml of sulfuric acid with a concentration of 0.5mol / L into a three-necked flask, and place the three-necked flask in a constant temperature water bath Stir on the pot to leach Cr 6+ , the temperature is controlled at 30°C, the rotational speed is controlled at 300r / min, and the leaching time is 3h.

[0029] (2) Weigh 10g of sawdust and put it into a beaker, add 50ml of 70% concentrated sulfuric acid, put it in a constant temperature water bath for hydrolysis, control the hydrolysis temperature at 40°C, and control the hydrolysis time at 30min.

[0030] (3) After the stirring and leaching in step (1) ends, filter and remove the filter residue, add the sawdust solution hydrolyzed in step (2), and reduce the hexavalent chromium leached in the c...

Embodiment 2

[0034] A method for removing hexavalent chromium in chromium slag, specific operation steps:

[0035] (1) Grind the chromium slag to be treated, weigh 25g, add 125ml of sulfuric acid with a concentration of 0.5mol / L, stir and leach Cr 6 + , the temperature is controlled at 40°C, and the leaching time is 4h.

[0036] (2) Weigh 15g of sawdust, add 75ml of 80% concentrated sulfuric acid for hydrolysis, control the hydrolysis temperature at 50°C, and control the hydrolysis time at 50min.

[0037] (3) After the stirring and leaching in step (1) ends, filter and remove the filter residue, add the sawdust solution hydrolyzed in step (2), and reduce the hexavalent chromium leached in the chromium residue, the temperature is controlled at 60 ° C, and the time is 3h.

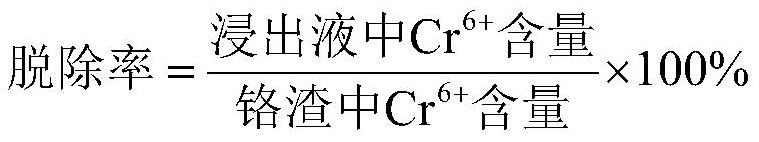

[0038] (4) Utilize ultraviolet spectrophotometry to measure hexavalent chromium concentration in the upper clear night, obtain hexavalent chromium removal rate 92.6%, add sodium hydroxide, control solution pH to 7-9, m...

Embodiment 3

[0041] A method for removing hexavalent chromium in chromium slag, specific operation steps:

[0042] (1) Grind the chromium slag to be treated, weigh 30g, add 150ml of sulfuric acid with a concentration of 1mol / L, and stir to leach Cr 6 + , the temperature is controlled at 50°C, and the leaching time is 4h.

[0043] (2) Weigh 10 g of sawdust, add 50 ml of 90% concentrated sulfuric acid for hydrolysis, control the hydrolysis temperature at 60° C., and control the hydrolysis time at 50 minutes.

[0044] (3) After stirring and leaching in step (1), remove the filter residue by filtration, add the sawdust solution hydrolyzed in step (2), and reduce the hexavalent chromium leached from the chromium residue, the temperature is controlled at 60°C, and the time is 3h .

[0045] (4) Utilize ultraviolet spectrophotometry to measure hexavalent chromium concentration in the upper clear night, obtain hexavalent chromium removal rate 96.2%, add sodium hydroxide, control solution pH to 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com