Tower-type enhanced oxidation system and method for preparing hydrogen peroxide

A hydrogen peroxide and tower-type technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of insufficient mixing and oxygen utilization Low yield, low product yield and other problems, to achieve the effect of easy operation, improved application area, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

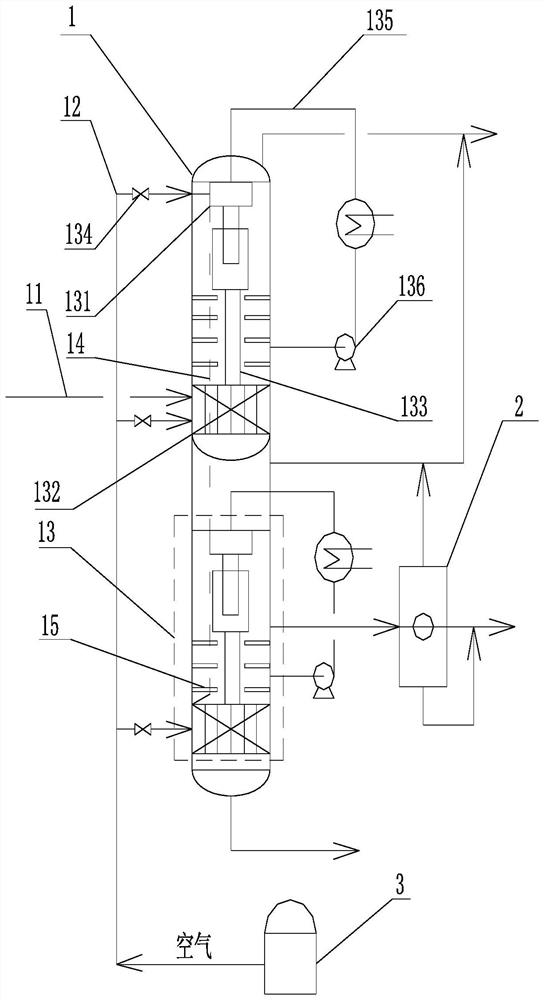

[0047] refer to figure 1 As shown, it is a tower-type enhanced oxidation system for preparing hydrogen peroxide according to an embodiment of the present invention, which mainly includes an oxidation tower 1, and multiple groups of mixed micro-interface generator units 13 arranged inside the oxidation tower 1. In the oxidation tower 1, mainly Hydrogenated anthraquinone reacts with air to produce hydrogen peroxide. In order to improve the oxidation effect, a multi-layer grid 15 is arranged in the oxidation tower 1, and a downcomer 14 for drainage is arranged on the inner wall.

[0048] This embodiment is two groups of mixed micro-interface generator sets 13, the mixed micro-interface generator sets 13 are arranged sequentially from top to bottom, and each set of mixed micro-interface generator sets 13 includes an upper-mounted micro-interface generating set connected as a whole. device 131 and a lower-mounted micro-interface generator 132, a gas-liquid emulsion channel 133 is a...

Embodiment 2

[0060] Other operating steps are consistent with Example 1, except that the oxidation heating constant temperature is 45° C., and the reaction pressure of oxidation tower 1 is 0.25 MPa. Analysis results: the conversion rate of hydrogenated anthraquinone is 97%, and the utilization rate of oxygen is 97%.

Embodiment 3

[0062] Other operating steps are consistent with Example 1, except that the oxidation heating constant temperature is 55° C., and the reaction pressure of oxidation tower 1 is 0.35 MPa. Analysis results: the conversion rate of hydrogenated anthraquinone is 97%, and the utilization rate of oxygen is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com