Environment-friendly quartz sand purification process

A kind of quartz sand, environmental protection technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problem of high cost of waste liquid treatment, achieve excellent iron removal rate, reduce the possibility of hydrolysis to form silicon dioxide precipitation, and reduce waste of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

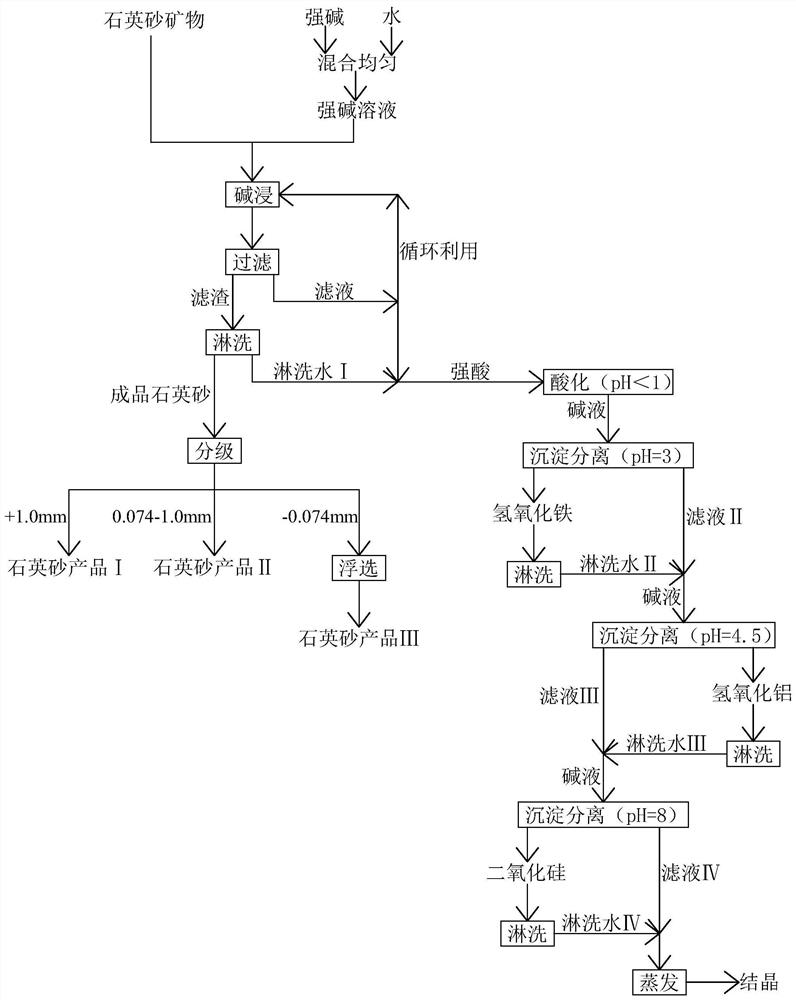

[0069] refer to figure 1 , an environment-friendly quartz sand purification process, comprising the following steps:

[0070] Alkali leaching: Stir and mix 1000kg dry weight of quartz sand minerals and 1000kg mass percentage concentration of 20% sodium hydroxide solution together, and raise the temperature to 90°C, stir and react at 90°C for 3 hours to obtain a solid-liquid mixture , wherein the yield of particles with a particle size of less than 0.074mm in quartz sand minerals is 8.87%.

[0071] Filtration: Centrifuge the solid-liquid mixture with filtration equipment to obtain filter residue and filtrate I.

[0072] Rinse: rinse the filter residue with water until the pH value of the rinse water is 7 to obtain the finished quartz sand and rinse water I.

[0073] Classification: Screen the finished quartz sand after rinsing into two specifications of particle size 1.0mm two kinds of particle size, >1.0mm particle size quartz sand is quartz sand product I, 0.074-1.0mm parti...

Embodiment 2

[0081] An environment-friendly quartz sand purification process, comprising the following steps:

[0082] Alkali leaching: Stir and mix 1000kg dry weight of quartz sand minerals and 1500kg mass percentage concentration of 30% sodium hydroxide solution together, and raise the temperature to 100°C, stir and react at 100°C for 3 hours to obtain a solid-liquid mixture , wherein the yield of particles with a particle size of less than 0.074mm in quartz sand minerals is 9.89%.

[0083] Filtration: Centrifugal filtration of solid-liquid mixture with filtration equipment to obtain filter residue.

[0084] Rinse: rinse the filter residue with water until the pH value of the rinse water is 8 to obtain the finished quartz sand.

[0085] Classification: Screen the finished quartz sand after rinsing into two specifications of particle size 1.0mm two kinds of particle size, >1.0mm particle size quartz sand is quartz sand product I, 0.074-1.0mm particle size quartz sand is quartz sand product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com