Preparation method of BaTiO3 microcrystalline powder

A technology of microcrystalline powder and powder, which is applied in the field of preparation of BaTiO3 microcrystalline powder, can solve the problems of deterioration of material density, coarsening of microstructure, and reduction of mechanical strength, and achieves good repeatability, low price, and high application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw material: Analytical pure BaCO 3 、TiO 2 , molten salt additive NaCl

[0023] Specific steps are as follows:

[0024] (1) Synthesized tetragonal BaTiO 3 Powder: with BaCO 3 and TiO 2 As raw material, according to BaTiO 3 Stoichiometric weighing of chemical raw materials, ball milling and mixing for 12 hours, drying, and synthesis of equiaxed BaTiO by traditional solid-state method at 1350°C and heat treatment for 3 hours 3 powder; and perform secondary ball milling to refine BaTiO 3 Powder, product A is finally obtained.

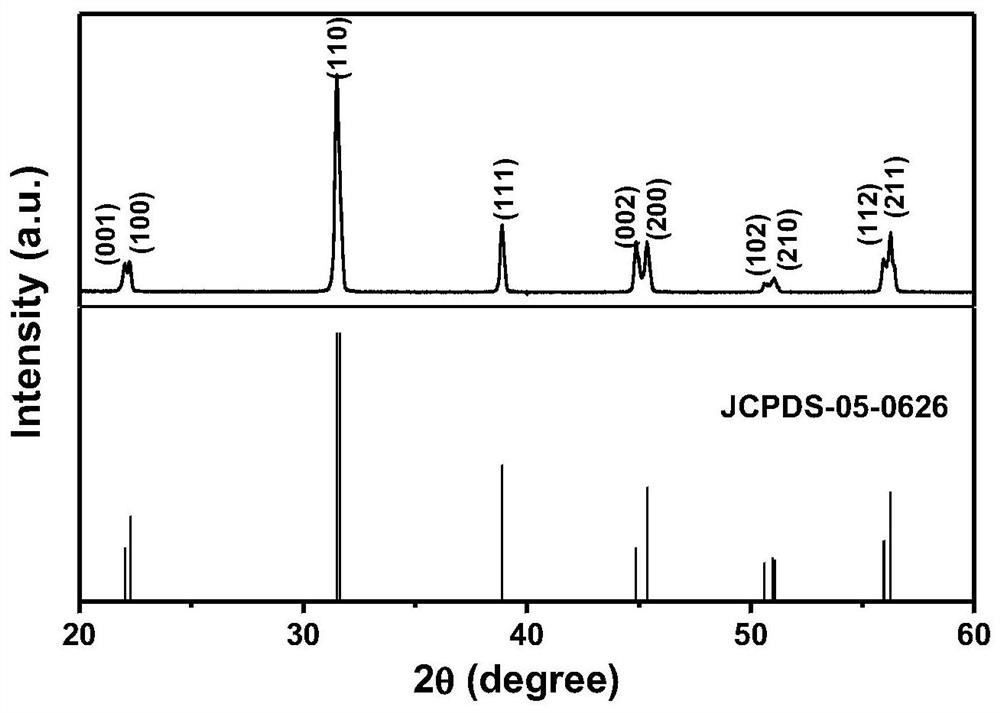

[0025] Product A (tetragonal BaTiO 3 powder) X-ray diffraction pattern and PDF standard card (JCPDS 05-0626) comparison example figure 1 shown.

[0026] from figure 1 found that the synthesized BaTiO 3 All the diffraction peaks of the XRD spectrum of the powder are consistent with the tetragonal BaTiO of the standard PDF spectrum (JCPDS05-0626). 3 The diffraction peaks of the two are completely consistent, indicating that pure tetragon...

Embodiment 2

[0034] Raw material: Analytical pure BaCO 3 、TiO 2 , molten salt additive NaCl

[0035] Specific steps are as follows:

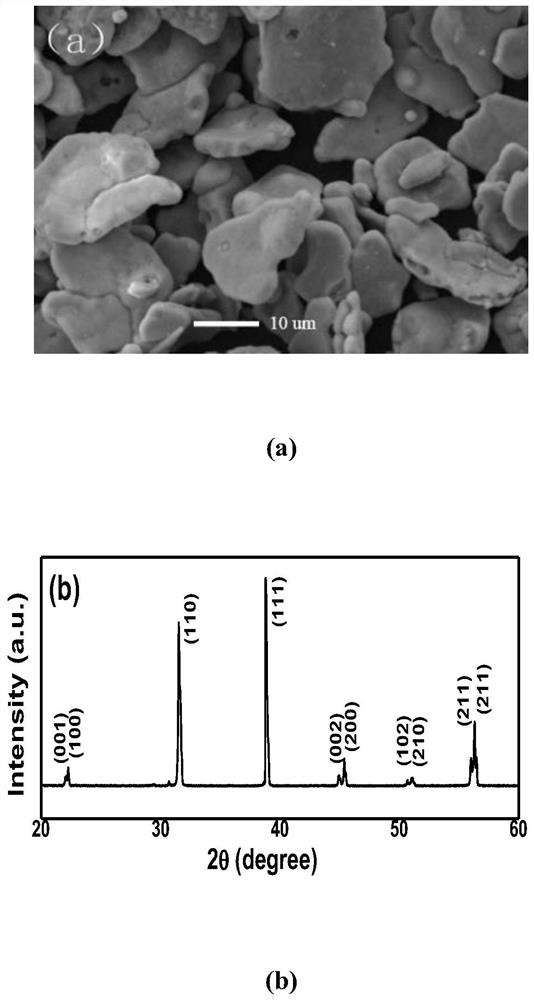

[0036] (1) Synthesized tetragonal BaTiO 3 Powder: BaCO 3 and TiO 2 As raw material, according to BaTiO 3 Stoichiometric weighing of chemical raw materials, ball milling and mixing for 12 hours, drying, and synthesis of equiaxed BaTiO by traditional solid-state method at 1350°C and heat treatment for 3 hours 3 powder; and perform secondary ball milling to refine BaTiO 3 Powder.

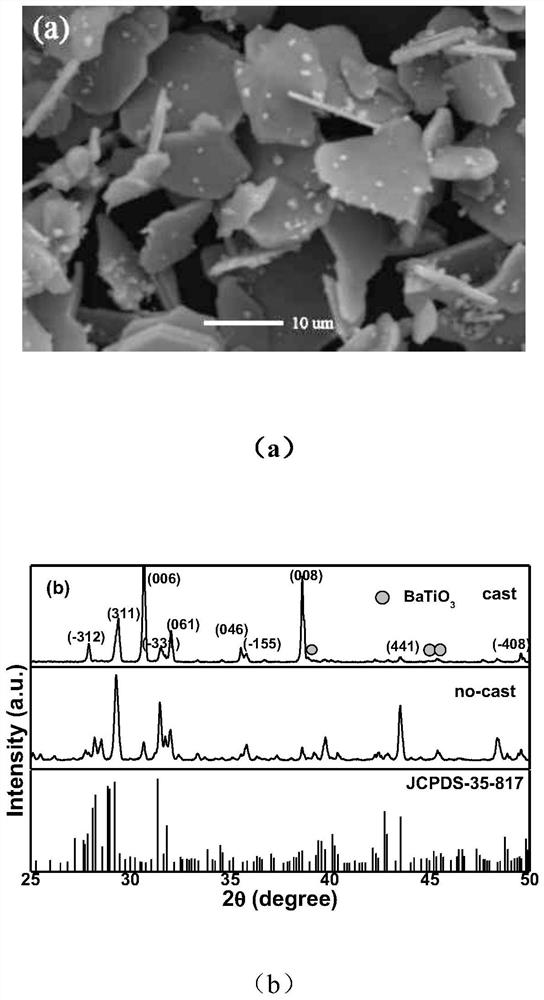

[0037] (2) Preparation of flake (001) Ba 6 Ti 17 o 40 Powder: In order to fully mix the reactants, the solid-phase synthesized BaTiO 3 Powder and TiO 2 Mixing and ball milling for 12h, in which BaTiO 3 and TiO 2 The molar ratio is 6:9; then add NaCl molten salt of the same quality as the oxide raw material to continue ball milling, and dry at 80°C after discharge; the dried powder is sealed in a crucible, first at 800°C for 1h Melt the NaCl molten salt to a molten stat...

Embodiment 3

[0040] Raw material: Analytical pure BaCO 3 、TiO 2 , molten salt additive NaCl

[0041] Specific steps are as follows:

[0042] (1) Synthesized tetragonal BaTiO 3 Powder: BaCO 3 and TiO 2 As raw material, according to BaTiO 3 Stoichiometric weighing of chemical raw materials, ball milling and mixing for 12 hours, drying, and synthesis of equiaxed BaTiO by traditional solid-state method at 1350°C and heat treatment for 3 hours 3 powder; and perform secondary ball milling to refine BaTiO 3 Powder.

[0043] (2) Preparation of flake (001) Ba 6 Ti 17 o 40 Powder: In order to fully mix the reactants, the solid-phase synthesized BaTiO 3 Powder and TiO 2 Mixing and ball milling for 12h, in which BaTiO 3 and TiO 2 The molar ratio is 6:9; then add NaCl molten salt of the same quality as the oxide raw material to continue ball milling, and dry at 80°C after discharge; the dried powder is sealed in a crucible, first at 800°C for 1h Melt the NaCl molten salt to a molten stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com