Thick-wall super 13Cr seamless steel pipe with yield strength of 125 steel grade and production method

A seamless steel pipe, yield strength technology, applied in thick-walled super 13Cr seamless steel pipe and production field, can solve the problems of reduced plasticity and toughness, unusable, high brittleness, etc., to improve the yield and quality of finished products, reduce production costs, The effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

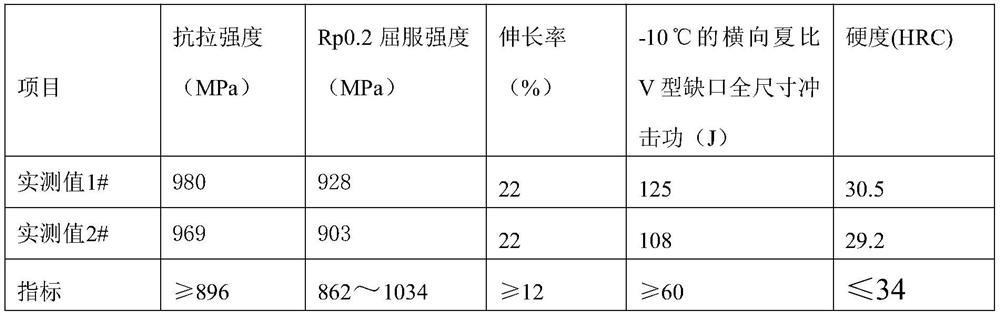

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with examples. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

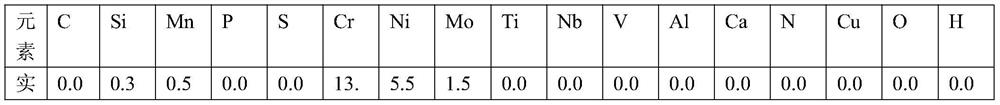

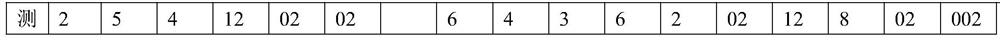

[0018] The thick-walled super 13Cr seamless steel pipe with a yield strength of 125 steel grades of the present invention has a production specification of φ133mm×wall thickness of 35mm, and its chemical composition is as shown in Table 1:

[0019] Table 1. φ133mm×35mm super 13Cr seamless steel pipe composition test data / (mass percentage%)

[0020]

[0021]

[0022] The production process of the thick-walled super 13Cr seamless steel pipe with a yield strength of 125 steel grades includes the following steps:

[0023] ⑴ Billet smelting, through electric furnace smelting + continuous casting process, to produce super 13Cr casting blank; the specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com