Thick-wall super 13cr seamless steel pipe with yield strength 125 steel grade and production method

A seamless steel pipe and yield strength technology, applied in the field of thick-walled super 13Cr seamless steel pipe and production, can solve the problems of reduced plasticity and toughness, unusable, high brittleness, etc., to improve the yield and quality, reduce production costs, The effect of good toughness

Active Publication Date: 2022-05-31

HANDAN XINXING SPECIAL TUBING CO LTD

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the case of the same material composition, L80-13Cr can be quenched and tempered to 125ksi steel grade by reducing the tempering temperature or tempering time, but at this time, the plasticity and toughness of this composition are greatly reduced, the brittleness is extremely high, and it is easy to crack ,can not be used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020]

[0021]

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

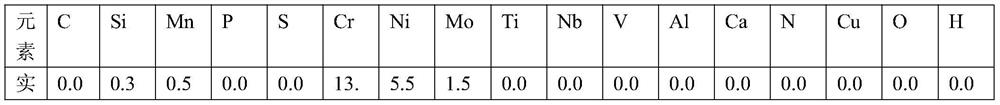

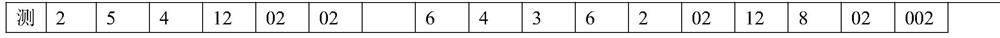

The invention relates to a thick-walled super 13Cr seamless steel pipe with a yield strength of 125 steel grade and a production method. The properties of the seamless steel pipe are: tensile strength ≥ 896 MPa, Rp0.2 yield strength 862-1034 MPa, elongation ≥ 12% . The production method of seamless steel pipe is: ⑴ electric furnace smelting + continuous casting to produce super 13Cr billet; ⑵ billet annealing to reduce hardness; ⑶ billet processing to remove surface scale, center looseness and cracks; ℃, hot extrusion molding; ⑸ preheating treatment, steel pipe heating 960 ℃ ~ 1010 ℃, blowing to cool to room temperature; ⑹ heating 960 ℃ ~ 1010 ℃, quenching oil rapid cooling, reheating 560 ℃ ~ 610 ℃, tempering treatment, Get super 13Cr steel pipe with 125 steel grade properties. The invention improves the finished product rate and quality of the seamless steel pipe and reduces the production cost. The seamless steel pipe has good surface quality, high mechanical properties after oil quenching heat treatment, high strength and good toughness.

Description

Thick-walled super 13Cr seamless steel pipe with yield strength 125 grade and production method technical field The invention belongs to the field of industrial equipment production, and particularly relates to a thick-walled super 13Cr with a yield strength of 125 steel grades Seamless steel pipe and production method. Background technique With the gradual exhaustion of shallow wells and oil fields that are easier to develop in the world, and the increasing demand for energy in various countries [0002] Forcing people to turn to CO2-corroded oilfields with deeper wells with harsher geological conditions. L80‑13Cr It is a kind of steel used for petroleum exploitation, which has good carbon dioxide corrosion resistance and is a low-cost corrosion-resistant alloy. In mining, L80‑13Cr seamless steel pipes are widely used. With the increase of oil well depth, geological conditions become complicated, and common low steel grade L80-13Cr is difficult to bear complicated ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/44C22C38/50C22C38/48C22C38/46C22C38/06C22C38/42C21D8/10C21D1/18

CPCC22C38/02C22C38/04C22C38/44C22C38/50C22C38/48C22C38/46C22C38/06C22C38/42C21D8/105C21D1/18Y02P90/70

Inventor 王锦永曹洪波周洁

Owner HANDAN XINXING SPECIAL TUBING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com