Preparation method of chinlon wool-like yarn with crystal fine glittering luster

A nylon and luster technology is applied in the field of preparation of nylon wool-like yarn, which can solve the problems of lack of crystal fine sparkle, poor wool-like effect of nylon wool-like yarn, inability to reflect natural fur luster, etc. Simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of nylon wool-like yarn with fine crystal luster, comprising the following steps:

[0034] (1) Put the dried raw PA6 chips (moisture content ≤ 50ppm) into the silo under nitrogen protection, melt through the screw extruder and accurately metered by the metering pump, and then enter the spinning assembly to set The pressure is 11MPa, and the thin stream of melt is sprayed out through the straight spinneret hole of the spinneret, and the thin stream of melt is cooled by side blowing to form curled primary fibers.

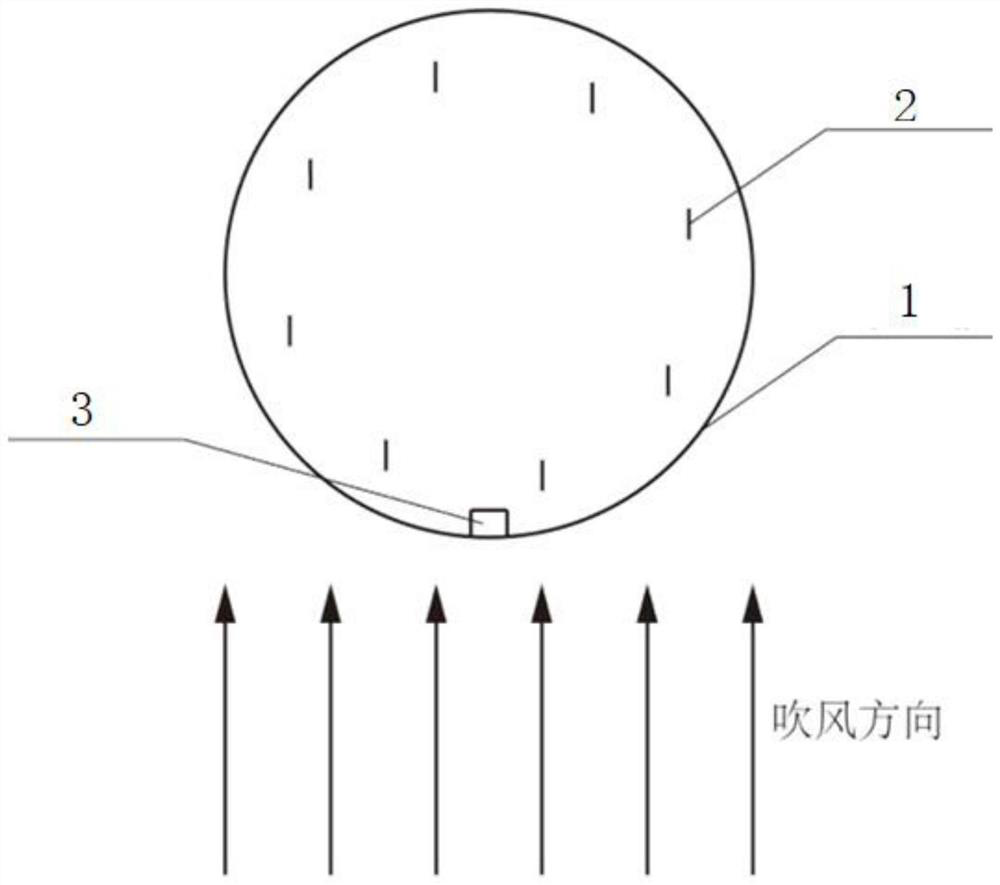

[0035] The melting temperature of the melt is controlled between 252-257°C. The inline spinneret holes 2 are evenly distributed in a circular shape on the spinneret 1, the number of inline spinneret holes is 8, and the aspect ratio of the inline spinneret holes is 17:1 (see figure 1 ). The blowing direction is parallel to the length direction of the straight spinneret hole, the wind speed is 0.38m / s, the wind temperature is 15°C, and the ...

Embodiment 2

[0041] A preparation method of nylon wool-like yarn with fine crystal luster, comprising the following steps:

[0042] (1) Put the dried raw PA6 chips (moisture content ≤ 50ppm) into the silo under nitrogen protection, melt through the screw extruder and accurately metered by the metering pump, and then enter the spinning assembly to set The pressure is 13MPa, and the melt stream is sprayed out through the straight spinneret holes of the spinneret, and the melt stream is cooled by side blowing to form curled primary fibers.

[0043] The melting temperature of the melt is controlled between 252-257°C. The inline spinneret holes 2 are evenly distributed in a circular shape on the spinneret 1, the number of inline spinneret holes is 8, and the aspect ratio of the inline spinneret holes is 18:1 (see figure 1 ). The blowing direction is parallel to the length direction of the inline spinneret hole, the wind speed is 0.5m / s, the wind temperature is 16°C, and the humidity is 90%. ...

Embodiment 3

[0049] A preparation method of nylon wool-like yarn with fine crystal luster, comprising the following steps:

[0050] (1) Put the dried raw PA6 chips (moisture content ≤ 50ppm) into the silo under nitrogen protection, melt through the screw extruder and accurately metered by the metering pump, and then enter the spinning assembly to set The pressure is 15MPa, and the melt stream is sprayed out through the straight spinneret hole of the spinneret, and the melt stream is cooled by side blowing to form a curled primary fiber.

[0051] The melting temperature of the melt is controlled between 252-257°C. The inline spinneret holes 2 are evenly distributed in a circular shape on the spinneret 1, the number of inline spinneret holes is 10, and the aspect ratio of the inline spinneret holes is 19:1 (see figure 1 ). The blowing direction is parallel to the length direction of the inline spinneret hole, the wind speed is 0.55m / s, the wind temperature is 18°C, and the humidity is 95%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com