Oil-water separation prediction method and device based on microcosmic distribution derivation of liquid drops

A technology of oil-water separation and prediction method, which is applied in the directions of measuring devices, analyzing materials, design optimization/simulation, etc., and can solve problems such as lack of physical theory, insufficient extension and stability, and difficulty in description

- Summary

- Abstract

- Description

- Claims

- Application Information

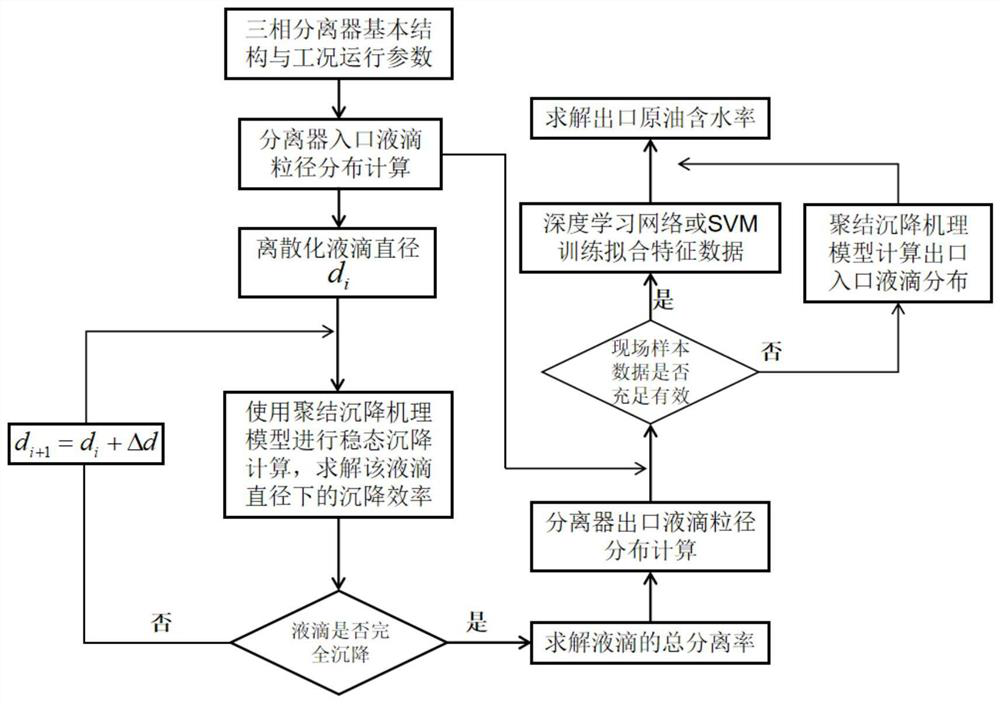

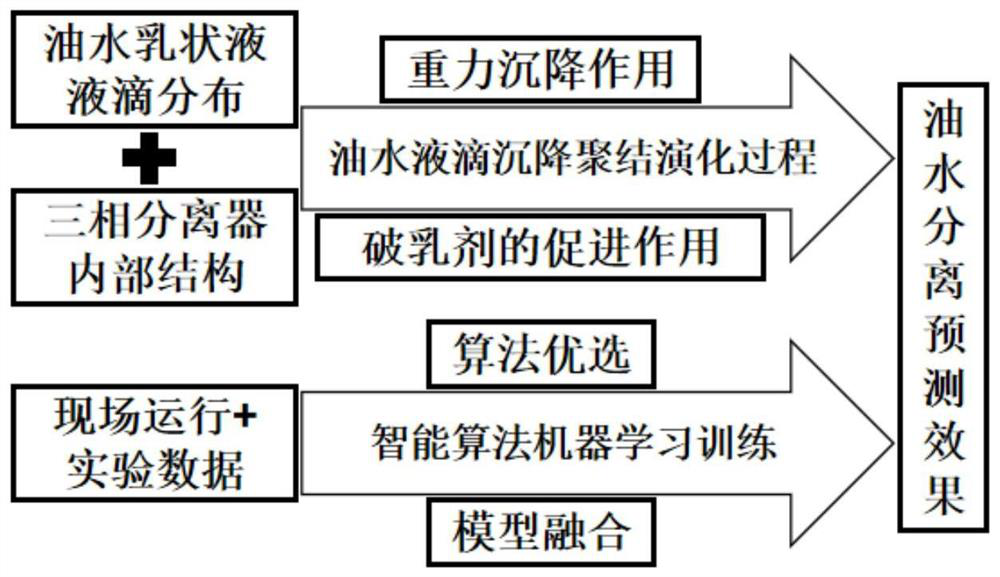

AI Technical Summary

Problems solved by technology

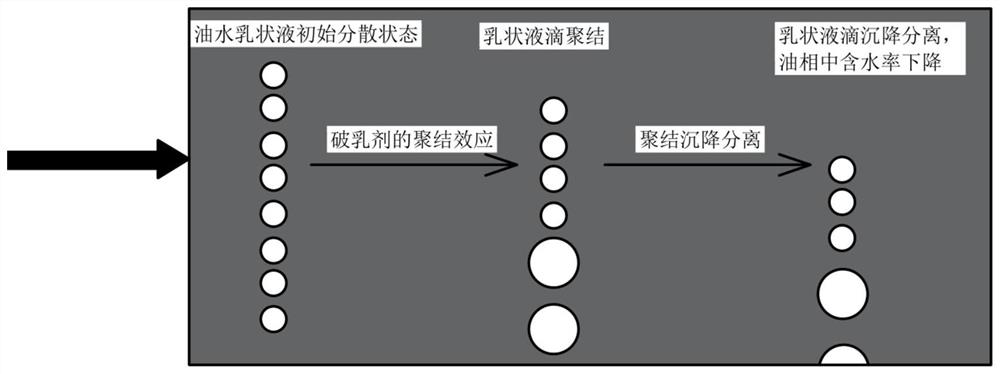

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Predicting the Separation Effect of Variations in Residence Time of a Three-Phase Separator

[0056] A medium-high water-cut oilfield adopts a horizontal three-phase separator as the main equipment for three-phase separation of oil, gas and water. The three-phase separator can quickly remove most of the free water in the incoming fluid from the wellhead. However, if the crude oil has poor emulsification stability or The demulsification effect is better, and the three-phase separator can reduce the water content of crude oil to 0.5% by heating or prolonging the residence time.

[0057] In this example, the three-phase separator dehydrated for 30 minutes, and the dehydration temperature was 30°C. The station crude oil was medium waxy crude oil with a density of 840kg / m 3 , viscosity is 5mpa s, oil-water interfacial tension is 12mN / m, separator diameter is 2.5m, oil-water separation effective length is 9m, separator inlet diameter is 0.2m, oil-water interface he...

Embodiment 2

[0061] Embodiment 2: Predict the separation effect of different influencing factors

[0062] The initial parameters are basically the same as in Example 1, the residence time is 30min, the initial temperature of demulsification and dehydration is set to 40°C, the oil-water interfacial tension is reduced to 10mN / m, and the crude oil density is increased to 850kg / m 3 , to predict the water content of crude oil after oil-water separation, the prediction results are shown in Table 1:

[0063] Table 1 Prediction results of oil-water separation effect under different basic parameters

[0064]

[0065] The prediction method calculation result of embodiment 2 shows, for the influence factor that influences oil-water separation effect, the prediction method of the present invention can well reflect the influence that influence factor changes for oil-water separation effect, for the unfavorable factor (oil-water density) of oil-water separation influence Difference reduction, temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com