Preparation method of high-nickel ternary material and application of high-nickel ternary material in positive plate of solid-state lithium ion battery

A high-nickel ternary material, lithium-ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problem of high-nickel ternary material capacity, cycle and rate performance deterioration, affecting the capacity and cycle of ternary materials. The problem of high performance, residual lithium and residual alkali content, to achieve the effect of improving electrochemical performance, uniform size, and low surface residual alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

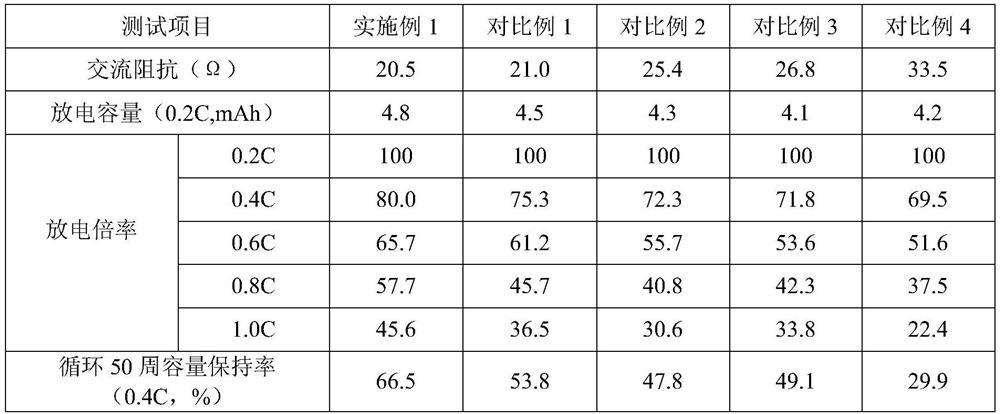

Examples

Embodiment 1

[0039] A solid-state lithium-ion battery positive plate, the preparation method of which is:

[0040] (1) PEO and LiClO with a mass ratio of 1:8 4 Dissolve in a mixed solvent of water and ethanol with a volume ratio of 1:1, stir at 50°C for 4 hours to obtain a mixed solution;

[0041] (2) The mixed solution is evenly coated on the surface of the LATP solid electrolyte layer, and after drying, a PEO coating layer with a thickness of 12 μm is obtained on the LATP solid electrolyte layer;

[0042] Wherein, the preparation method of LATP solid electrolyte layer is:

[0043] a) LiNO 3 , Al(NO 3 ) 3 9H 2 O, NH 4 h 2 PO 4 and CsClO 4 Add deionized water to dissolve, then add citric acid, stir well, then add titanium lactate, stir at 75°C for 18 hours to obtain a viscous liquid; among them, LiNO 3 , Al(NO 3 ) 3 9H 2 O, titanium lactate and NH 4 h 2 PO 4 The amount of addition is 1.3:0.3:1.7:3 according to the molar ratio of Li, Al, Ti, P, CsClO 4 The added amount of c...

Embodiment 2

[0054] A solid-state lithium-ion battery positive plate, the preparation method of which is:

[0055] (1) PEO and LiClO with a mass ratio of 1:7 4 Dissolve in a mixed solvent of water and ethanol with a volume ratio of 1:1, and stir at 45°C for 5 hours to obtain a mixed solution;

[0056] (2) The mixed solution is evenly coated on the surface of the LATP solid electrolyte layer, and after drying, a PEO coating layer with a thickness of 10 μm is obtained on the LATP solid electrolyte layer;

[0057] Wherein, the preparation method of LATP solid electrolyte layer is:

[0058] a) LiNO 3 , Al(NO 3 ) 3 9H 2 O, NH 4 h 2 PO 4 and CsClO 4 Add deionized water to dissolve, then add citric acid, stir well, then add titanium lactate, stir at 70°C for 20 hours to obtain a viscous liquid; among them, LiNO 3 , Al(NO 3 ) 3 9H 2 O, titanium lactate and NH 4 h 2 PO 4 The amount of addition is 1.4:0.4:1.6:3 according to the molar ratio of Li, Al, Ti, P, CsClO 4 The added amount ...

Embodiment 3

[0069] A solid-state lithium-ion battery positive plate, the preparation method of which is:

[0070] (1) PEO and LiClO with a mass ratio of 1:10 4 Dissolve in a mixed solvent of water and ethanol with a volume ratio of 1:1, stir at 55°C for 3 hours to obtain a mixed solution;

[0071] (2) The mixed solution is evenly coated on the surface of the LATP solid electrolyte layer, and after drying, a PEO coating layer with a thickness of 15 μm is obtained on the LATP solid electrolyte layer;

[0072] Wherein, the preparation method of LATP solid electrolyte layer is:

[0073] a) LiNO 3 , Al(NO 3 ) 3 9H 2 O, NH 4 h 2 PO 4 and CsClO 4 Add deionized water to dissolve, then add citric acid, stir well, then add titanium lactate, stir at 80°C for 10 hours to obtain a viscous liquid; among them, LiNO 3 , Al(NO 3 ) 3 9H 2 O, titanium lactate and NH 4 h 2 PO 4 The amount of addition is 1.2:0.2:1.8:3 according to the molar ratio of Li, Al, Ti, P, CsClO 4 The added amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com