A kind of electronic grade nitric acid production process

A production process and electronic-grade technology, applied in the field of electronic-grade nitric acid production technology, can solve problems such as poor nitric acid preparation process, and achieve the effects of avoiding excessive corrosion, improving service life, and avoiding violent reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

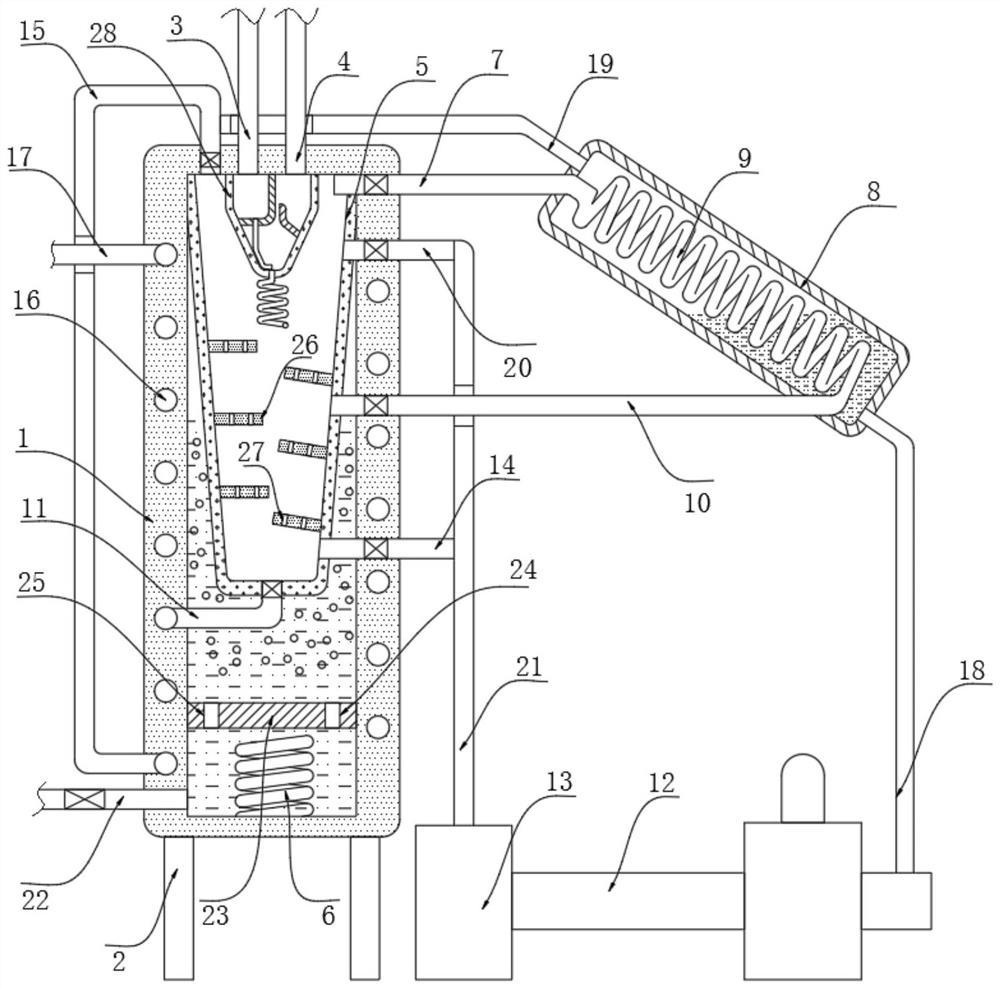

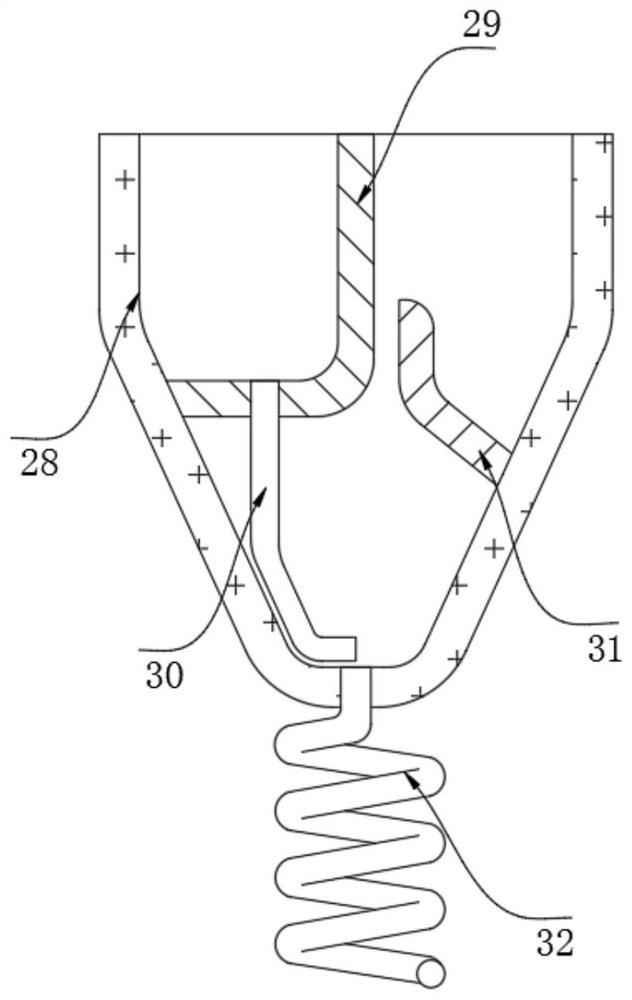

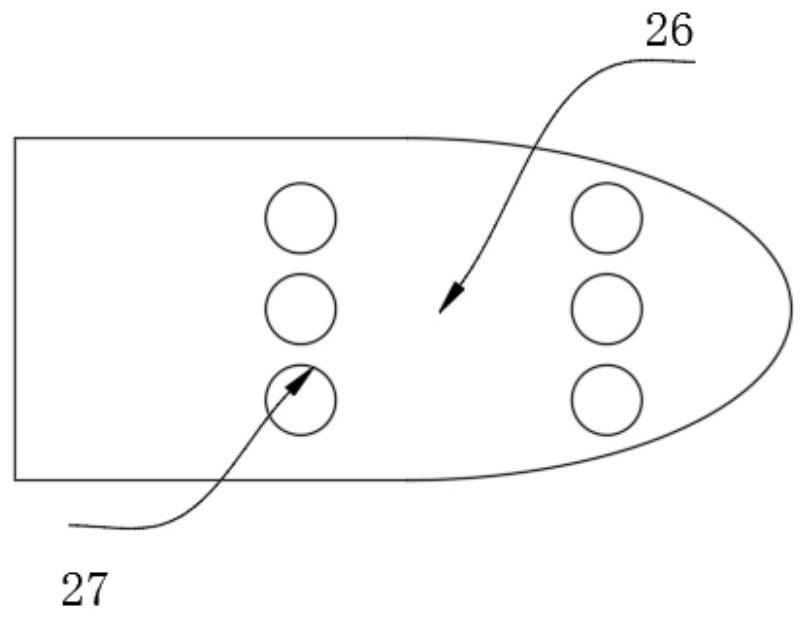

[0033] refer to Figure 1-3 , a kind of electronic grade nitric acid production technology, mainly comprises the following processing steps:

[0034] S1. Assembly and cleaning of the equipment: connect the intake pipe of the vortex tube 12 to the external air compressor, and connect the external air compressor to the air purifier to ensure that the air entering the vortex tube 12 is purified dust-free air. The use of dust-free air to replace the commonly used high-purity nitrogen can greatly reduce the processing cost and ensure that it will not cause pollution to subsequent processing; the interior of the heating jacket 5 is filled with water to clean the interior of the heating jacket 5 to ensure that the interior of the heating jacket 5 is clean, thereby reducing subsequent distillation impurities;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com